This article provides a comprehensive insight into the wound type rotor with slip rings, discussing their construction, working principles, types, applications, advantages, user concerns and solutions, purchasing guide, maintenance tips, and future predictions.

Introduction to Wound Type Rotor with Slip Rings

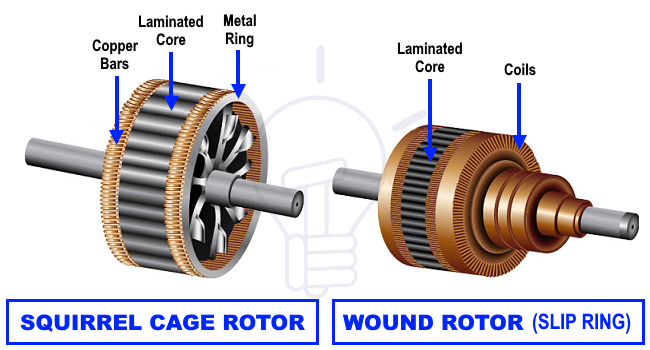

A wound type rotor is a crucial component of an AC induction motor. Essentially, it includes an iron core that is wound with conductive wire. Compared to their counterpart, squirrel cage rotors, the windings of a wound type rotor are connected through slip rings to external resistance.

The primary purpose of these wound type rotors is to convert electrical energy into mechanical energy through the rotating magnetic field created in the rotor, which, in turn, rotates and drives the machinery. The fact that additional resistance can be added to the rotor circuit makes these types of rotors highly adaptable to different load conditions, therefore enhancing the efficiency of the engine. With the right balance between the input factor, resistance, and rotor speed, these rotors function at optimal performance, contributing significantly to overall motor efficiency.

Now, that’s where slip rings come into play. Slip rings are essentially electrical connectors that allow the transmission of power and electrical signals from a stationary structure to a rotating one. Fitted on the shaft of the rotor, these rings allow for a smooth transfer of currents between two electrically conducted parts, without hindering the rotor’s movement.

In the context of a wound rotor, the slip rings and brushes provide a means for the rotor windings to be connected to external circuits while in rotation. The current induced in the rotor windings is transferred through the slip rings to the external resistors during start-up. Following the torque-speed characteristics, the resistors are gradually cut off as the motor increases speed, eventually leaving the rotor windings directly connected to the power supply.

In summary, wound type rotors with slip rings allow for precise control over the motor’s speed, providing valuable versatility in industrial applications where varying speeds and torques are required. Moreover, the use of slip rings ensures a steady yet flexible connection between the rotor windings and the external circuit, allowing for a smooth operation of the motor.

Construction and Working of Wound Type Rotor with Slip Rings

Design and Construction of Wound Type Rotor

A wound type rotor’s primary component is the core, generally made from laminated iron sheets arranged in a cylindrical shape and held together using strong rivets or welding methods. The laminations help to reduce eddy current losses and consequently, minimize heating within the rotor due to induced rotating magnetic fields.

Wrapped around the core are copper or aluminum windings, known as rotor windings, which are evenly distributed over the core surface. These windings are electrically connected in a series or parallel configuration, forming a closed-loop circuit. The rotor’s ends are connected to insulated conductive segments, which, in turn, are connected to slip rings.

Design and Construction of Slip Rings

Slip rings are circular, conductive bands, typically made from copper, brass, or silver, depending on the specific motor application and conductivity requirements. They are secured around the motor shaft and electrically connected to the rotor windings. The motor shaft holds these rings in place and ensures that the rings maintain their concentricity despite the rotation.

Brushes, typically made of graphite or other conductive materials, press gently against the slip rings, constantly maintaining an electrical connection between the rotating slip rings and the stationary external circuitry. The brush assembly is designed to ensure minimal wear and tear on both the brushes and the slip rings to maintain a reliable connection throughout the operational life of the motor.

Working Principle of Wound Type Rotor with Slip Rings

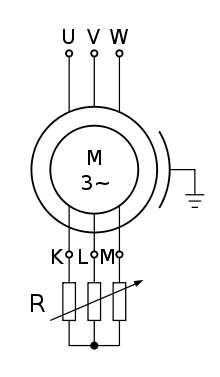

In a wound rotor induction motor operation, a three-phase power supply is applied to the stator windings. The stator windings then generate a rotating magnetic field, inducing a voltage in the rotor windings.

The slip rings ensure a continuous electrical connection between the rotating rotor windings and the stationary external resistor, even during the rotor’s rotation. The externally connected resistors, adjustable by the user, provide resistance to the induced rotor current.

During the motor start-up phase, the external resistance is at its maximum value. This results in high starting torque and low starting current for the motor. As the motor accelerates, the induced rotor current starts decreasing, and the external resistance is gradually reduced. Eventually, when the motor reaches its operating speed, the external resistors are fully bypassed, and the rotor windings are directly connected to the power supply.

In summary, the construction and working of wound type rotors with slip rings involve a combination of thoughtfully designed rotor windings, slip rings, and brush assembly, which enable highly controlled torque and speed adjustments. These rotors offer a stable and efficient power transmission solution for various industrial and commercial applications.

Types of Wound Type Rotors with Slip Rings

Wound type rotors accompanied by slip rings have diverse forms tailored to suit different motor applications. Among them are the following:

Standard Wound Type Rotors with Slip Rings

The standard model of wound type rotors comprises of laminated core with evenly distributed copper windings that conceptually take a 3-phase, double-layer, concentric type of winding configuration. The slip rings made from conductive materials are mounted on the shaft and are in conduction with the rotor windings. This type is ideal for heavy start-up load applications like compressors and conveyance systems due to its controllable speed and high starting torque.

Single-Phase Wound Type Rotor with Slip Rings

Single-phase wound type rotors also have their particular use cases. They may be applied in small power appliances, pumps, fans, and other domestic appliances. While they share essential characteristics with their 3-phase counterparts, these models only involve a single-phase winding on the rotor. This difference leads to a simpler design but a lower starting torque compared to three-phase wound rotors.

Integrated Control Wound Type Rotors with Slip Rings

In an increasingly automated industrial environment, an integrated control wound type rotor with slip rings is gaining momentum. The slip rings in this rotor type are connected to advanced control systems for regulating the additional resistance in the rotor circuit precisely. Moreover, instead of traditional graphite brushes, they use mercury or use wireless technology to transmit signals and power with reduced friction and maintenance requirements. These types of motors offer an enhanced level of control over motor speed and torque, making them suitable for sophisticated robotic, machining, or automation tasks.

While all these wound type rotors capitalize on the ability to control motor characteristics through the regulation of rotor circuit resistance, their designs and implementations vary significantly. Understanding these differences is crucial when selecting a rotor type, considering factors such as the application’s power requirement, operating conditions, maintenance cost, and desired level of control over motor operation.

Wound Type Rotor with Slip Rings Application Areas

As inherently versatile equipment, wound type rotor motors with slip rings find diverse applications across a range of industrial, commercial, and domestic sectors. They are the preferred choice wherever controlled speed, high starting torque, and efficient operation under varying load conditions are required.

Industrial Applications

In the industrial sector, wound type rotors with slip rings are particularly utilized in heavy machinery and high-torque applications. Examples include cranes and hoists, where motors with high starting torques are essential, and the torque needs precise control to handle materials safely. Wind turbines also use these rotors due to the variability in wind speed requiring flexible control. Similarly, in industrial conveyor systems, the ability to control motor speed becomes crucial in handling different throughput rates.

Commercial and Domestic Applications

In commercial and domestic settings, single-phase wound type rotor motors with slip rings can often be found in appliances like washing machines and fans. These applications demand motors that can start under load and run at different speeds, attributes offered by wound type rotors efficiently.

Electric Vehicle Applications

In the growing field of Electric Vehicles (EVs), wound type rotor motors with slip rings are beginning to carve a space for themselves. The ability to control the motor’s torque and speed directly is crucial while navigating different road conditions and gradients, which is achievable with these types of motors.

Mining Industry

The mining industry, which requires machinery to operate under high-torque and varying load conditions, also employs wound type rotors with slip rings. Applications include drilling machines, excavators, and conveyor systems, where a high degree of speed control is essential.

To sum up, the industries where wound type rotors with slip rings find use are diverse, and the applications innumerable. The blend of excellent speed control, high starting torque, and operational efficiency ensures their pivotal role in an array of systems, whether it is moving a crane, washing clothes, powering an electric car, or mining for resources.

Advantages of Wound Type Rotor with Slip Rings

Wound type rotors with slip rings offer several inherent advantages, making them a preferred choice for various applications across multiple industries. The key benefits revolve around their efficiency, adaptability, and longevity.

Efficiency

Wound type rotors are highly efficient due to their design and operation. The ability to adjust the external resistance allows these rotors to maintain optimal operation across different load conditions. These rotors are capable of creating high starting torques, minimizing the starting current, and avoiding electrical surges. The controlled operation ensures less energy dissipation as heat and better power utilization, contributing to higher overall efficiency.

Adaptability

The adaptability of wound type rotors with slip rings stands out amongst other alternatives. These motors have a capacity for a wide range of speeds and torques by adjusting external resistance, making them versatile for various applications. Whether it’s for domestic appliances or industrial machinery, where varying speed or high starting torque is required, wound type rotors can handle the task effectively.

Longevity

Dependable durability is another advantage of wound type rotors with slip rings. Though the casual impression may suggest that slip rings and brushes could wear out quickly due to constant physical contact, in reality, their design ensures reduced ware. Slip rings are usually made from highly conductive and durable materials, while the brushes are composed of materials like graphite, which has self-lubricating properties. With proper maintenance, these components demonstrate remarkable durability, leading to considerable motor life.

Moreover, the risk of motor burnout decreases with wound type rotors as they are capable of operating under higher loaded conditions without drawing excessive current.

In conclusion, the marked efficiency, superior adaptability, and notable longevity of wound type rotors with slip rings offer substantial benefits. These factors compound to not just enhance motor performance but also significantly contribute towards the sustainability of projects by reducing energy consumption and extending the operational life of the machinery.

Wound Type Rotor with Slip Rings User Concerns and How to Address Them

Given the crucial role of wound type rotors with slip rings in various applications, users understandably have certain concerns related to quality, maintenance, longevity, durability, and cost. Here’s a discussion of these concerns and effective ways to address them.

Quality

Quality assurance is a paramount concern, as inferior quality windings, slip rings, or brushes could lead to frequent motor failures and reduced efficiency. Users should ensure purchasing from reputable manufacturers that adhere to strict quality control procedures in their production process. Checking for appropriate certifications, like ISO or equivalent, is also advisable as it adds another layer of quality assurance.

Maintenance and Repair

Maintenance might seem daunting given the inherent moving parts (brushes and slip rings) involved. However, regular check-ups can ensure the optimal functioning of these rotors. Cleaning the brushes and slip rings, checking and maintaining brush pressure, and ensuring the insulation resistance of windings are part of routine maintenance. For repairs, it is always recommended to use professional services to prevent unintentional damage to the motor.

Longevity and Durability

Concerns about the lifespan of wound type rotors can be addressed by handling and maintaining them appropriately. Apart from regular maintenance, avoiding severe mechanical shocks and vibrations, ensuring sufficient cooling (ambient temperature and cooling method of the motor), and preventing the motor from running under extreme or severe overload conditions will help preserve the longevity of these rotors.

Costs

The economic aspect often gives rise to users’ concerns. The wound type rotors with slip rings may tend to be more expensive in terms of initial investment compared to other motor types. But looking at the bigger picture, the long-term benefits concerning efficiency, adaptability, and longevity, coupled with lower maintenance costs, make these rotors a cost-effective solution over their operational life span.

By appropriately addressing these concerns – assuring quality, conducting targeted maintenance and repairs, handling appropriately for extended service life, and linking initial costs to long-term benefits – users can draw significant value from wound type rotor motors with slip rings. They can thereby reap the value-for-money benefits offered by these motors, ensuring high operating efficiency across a range of applications.

Purchasing Guide for Wound Type Rotors with Slip Rings

When considering acquiring a wound type rotor with slip rings, there are several factors that potential buyers should pay attention to. The following detailed guidelines provide insights on certifications, technical specifications, warranty conditions, and other essential aspects to be aware of during the purchasing process.

- Certifications and Standards: Ensure that the manufacturer follows industry standards and possesses relevant certifications like ISO or equivalent. These certifications are indicative of the manufacturer’s commitment to quality control, safety, and reliability.

- Technical Specifications: Carefully examine the technical specifications of the motor, such as:

- Select a rotor that aligns with the specific requirements of your application in terms of power output, speed, voltage, and efficiency.

- Environment and Mounting Conditions: Consider the environment that the motor will be operating in and ensure the selected rotor is suitable for:

- Working temperature range: This includes the ambient temperature and the motor’s cooling method.

- Mounting arrangement: The position and configuration of the motor, such as horizontal, vertical, or other orientations. Make sure the chosen rotor is compatible with your installation requirements.

- Warranty and Support: Thoroughly read and understand the warranty conditions offered by the manufacturer. Additionally, check for the availability of after-sales support and services, such as maintenance and repair options, ensuring these provisions are easy to access for reliable long-term motor operation.

- Manufacturer Reputation: Research and verify the manufacturer’s reputation in the industry. Look for testimonials, referrals, or reviews from previous clients to gauge their experience with the manufacturer’s products and customer support.

- Price: Compare prices of wound type rotors with slip rings from various manufacturers to find one that offers a balance between cost-effectiveness and quality. Remember, the least expensive option may not always be the best when considering long-term performance and durability.

- Availability of Spare Parts: Ensure that spare parts, such as slip rings and brushes, are promptly available and can be easily procured from the manufacturer or their authorized distributors.

- Customization Options: Some manufacturers offer customization options to meet specific application requirements. If you need a unique design or performance, explore the manufacturer’s ability to provide customized solutions.

By carefully analyzing and considering all these factors during the purchase process, you can successfully select a wound type rotor with slip rings that aligns with your application requirements, ensuring optimal performance, durability, and value for money.

Maintenance Tips for Wound Type Rotors with Slip Rings

Proper maintenance of wound type rotors with slip rings ensures extended service life, reliability, and efficient operation. The following is a comprehensive breakdown of essential maintenance steps, schedules, and tips to help users maintain the efficiency and longevity of these rotors.

- Scheduled Routine Inspection: Perform routine inspections according to the manufacturer’s recommendations, which typically range from weekly to quarterly, depending on usage and operating conditions. Regular inspections can help identify and rectify minor issues before they escalate into more significant problems.

- Cleaning and Lubrication: Periodically clean slip rings and brushes to remove dirt, dust, and debris, which could hinder their performance and cause excessive wear. Ensure the brushes move freely in their holders. As most brushes are self-lubricating, extra lubrication is generally not needed. Instead, focus on checking brush pressure and contact to maintain optimal electrical contact with the slip rings.

- Brush and Slip Ring Examination: During routine inspection, check for excess wear or damage to the brushes and slip rings. Replace brushes when they reach their wear limit (usually indicated in their user manual). Resurface slip rings if they’re grooved, uneven, or burnt, and replace them if irreparably damaged.

- Insulation Resistance Testing: Regularly test the insulation resistance of the windings; this test helps identify potential motor issues such as insulation deterioration or moisture ingress. The frequency of testing depends on the motor type, age, and environmental factors; consult your user manual or motor professional for guidance.

- Vibration and Noise Monitoring: Routinely monitor the motor for aberrant vibration and noise levels, indicating possible mechanical issues like misalignment, bearing wear, or loosening of various components. Maintenance professionals can use specialized tools, such as vibration analysis equipment, to pinpoint the source of the issue and take corrective action.

- Bearing Maintenance: Check the bearings for signs of wear, corrosion, or abnormal heating, as these elements ensure smooth motor operation. Follow the manufacturer’s guidelines for lubrication, re-greasing, and replacement intervals, as well as using appropriate lubricants.

- Overload Protection: Avoid running the motor under extreme or prolonged overload conditions that can exceed its rated capacity. Overloads can contribute to accelerated wear and tear, reducing the rotor’s longevity and efficiency.

- Visual Inspection for External Damages: Carefully inspect the motor housing, casing, and other external components for signs of wear, corrosion, or damage. Ensure these components offer protection against environmental factors like dust, moisture, and impacts.

Overall, proper and timely wound type rotor maintenance, along with adherence to usage guidelines and environmental considerations, plays an essential role in prolonging rotor lifespan and maintaining peak efficiency. By following the above tips and seeking professional assistance when needed, users can ensure optimal performance and durability of their wound type rotors with slip rings.

Conclusion

With advancements in technology and evolving applications, wound type rotors with slip rings are anticipated to witness innovations and have expanding application areas. This section briefly predicts future trends and applications while summarizing the key points discussed throughout the article.