Who said you could not make your slip ring in the comfort of your house? Yes! It is possible. Well, like many manufacturers are making the devices, you can also make yours using readily available materials at home. Are you wondering how? Read below and learn.

Industrial settings and other devices use slip rings to transfer signals and currents. If you want the effectiveness of a slip ring at home, you can improvise what you have within your reach to make a slip ring to use if you do not want to spend money on one.

It can be for your windmill, local connections at home, or for your motor. Just as the slip ring finds extensive uses in marine, military, robotics, and wind turbines, you can use it too to transfer data, electric currents, or signals from rotating parts to stationary parts of your device.

Back to Basics, What Is a Slip Ring?

There is a lot of information on the internet about slip rings. Many manufacturers are making the device and selling it to manufacturers to use in their devices. Moreover, if you are looking for a way to make one at home, most probably you know what it is, right?

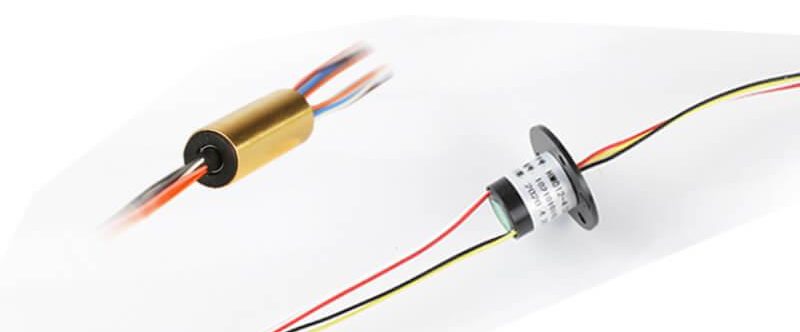

Quick fact, a slip ring is a device that efficiently transfers electric currents, signals, or data from stationary to rotary parts to effectively in rotating parts. They do so without any damage to any part. So, are you looking forward to making your first slip ring?

What Are the Rules?

The procedure is for you to learn how to make a windmill slip ring. It works if the rectifier is at the alternator, so what you need is a slip ring or two to transfer power down the mast. You use timber as an insulator since it is readily available, easy to work with, and will not melt.

Making a slip ring requires you to save the cash you could have bought it with. It means using what you have at hand or available in your local hardware store to make a slip ring that will function just like a slip ring from what you have at hand.

What is fantastic is that you make the slip ring perfect for your device. You know the device you want to make the slip ring for. It makes it easier for you to have a useful slip ring to work efficiently to give you the results you want.

What Do You Need?

· Zinc-coated steel plate/ copper sheet/ copper tube

· Wood to act as an insulator

· Bolts to hold them together

· Tape

· A motor

· Brass screw

· Steel strapping

· Sandpaper

The Procedure of Making a Robust Slip Ring for a Windmill

How do you come up with a slip ring that will suit your purpose of transferring electric current to and from your windmill? Follow the following procedure:

1. First, since you are going to use a mast, use the tape to fix the timber insulator onto the pole. To roll the slip ring, make a slightly smaller radius.

2. Next is to curve the steel for the slip ring. A scrap pipe can aid you in rolling the slip ring to get a nice round curve. Alternatively, you can use a large diameter exhaust, steel, or copper pipe that is large enough to fit at the mass with the wood insulator in place.

3. Once you have the correct diameter, cut the end square and put them together for welding. You have the option of using a plate behind the slip ring and riveting the ring together since welding can be a challenge.

4. File the sharp edges so as not to leave any sharp corners. For the rivets, make sure they are not in the path of the brushes. How do you do that? by placing them on the outside.

5. Next is making the connection joints. Drill the mounting holes evenly around the slip ring according to the timber insulators. Make sure the holes are 10mm in from one side. To give brushes a wide area to slide without hitting the mounting screw. Also, remember to drill a hole for the pole take-off point.

6. Drill the timber insulator onto the slip ring. Remember the 10mm space and allow 30m or more at the ends for the more comfortable placing of the slip ring onto the mast.

7. Next is the installation of the brushes. If you can find carbon brushes, they are the best. For the motor, you can look for one with a local electrical repair. They may have motors from washing machines, vacuum cleaners, or cloth dryers. Look for those with brushes in them.

8. Choose to use brass bolts as brush material, as they are naturally slippery and a good conductor of electricity, you can also use the brass knobs for drawers. Make sure you have to brush one on each side to ensure good contact.

9. To spring the brushes so they push against the slip ring, use a pliable material such as steel strapping. Cut the strapping tape to a length, then align it and tie it to the slip ring. Use straps that are more than twice or three times its length to increase tension.

10. To make a toothbrush holder, use square hardwood 20mm thick and two grooves to keep the strap square. Drill holes for the mounting bolts to fit right in. Check to make sure the brushes are on the opposite side of the slip ring and that the brushes do not foul the slip ring bolts.

11. In each brass bolt, feed the power. Do not use the steel strapping to supply power because the spring tension changes once it becomes hot.

12. To bend the brushes and give better electro connections between the slip rings and brushes, take 100-grip sandpaper and wrap it around the slip ring with the rough side out when rotating, rotate the brush assembly around the slip ring for several turns.

Conclusion

You see! It is that simple. You can make a simple slip ring for your windmill in the comfort of your homestead. Look for locally available materials and follow the above steps to make your first robust slip ring.

See What We Can Do