In the world of electromechanical, there are many types of slip rings. Manufacturers strive to make slip different slip rings that solve issues transmission of power and signals in devices that rotate as they work. One of the slip rings is the through-hole slip ring.

It is a slip ring that has uses in various devices and automotive. To answer the question of what the through hole slip ring is, you are going to read what the slip ring is, its components uses, and advantages of using the slip ring. Scroll along and learn.

Table of Contents

- What Is Through-Hole Slip Ring?

- History of the Through Hole Slip Ring

- Standard of Through Hole Slip Ring

- Components of Through-Hole Slip Ring

- Through Hole Slip Ring Made of Material

- How to Make a Through Hole Slip Ring

- How Does the Through-Hole Slip Ring Work?

- Different Types of Through Hole Slip Rings

- Why Through Hole Slip Ring Is Important

- Through-Hole Slip Ring – the Applications

- What Are the Characteristics of the Through Hole Slip Ring?

- Advantages of Using the Through-Hole Slip Ring

- Where to Buy Through Hole Slip Ring

- Some Important Things About Through Hole Slip Ring

- Frequently Asked Questions

What Is Through-Hole Slip Ring?

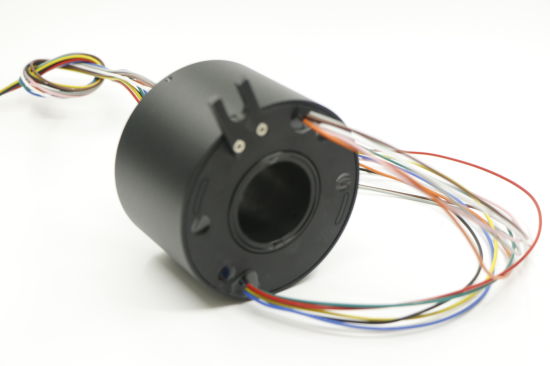

If you have a look at slip rings, the through-hole slip ring is one that has a hollow shaft at the center. The manufacturers make the slip ring for you to install with a flange on a sleeve bracket. It has a free inner space for the internal connecting of the rotor to the rotating shaft of your machine or device. The hole can also lead through pipes or cables connected to the rotating part.

Due to the design of the slip ring, many people are finding it convenient to use the slip ring. That is because it is easy to install, carries more power, and you can install it on many devices. So, what is a through-hole slip ring? What is its composition?

History of the Through Hole Slip Ring

Through-hole slip rings, also known as “Hollow Shaft Slip Rings”, have evolved significantly over time. Birthed from the necessity for a slip ring to provide not just the rotational electrical connection but also allow space for other operational components, Through hole slip rings marked a significant leap in the slip ring technology. Through hole slip rings, a custom variant of traditional slip ring assemblies was developed in response to specific industry needs. Over time as technology advanced and became more complex, the requirement for a more accommodating design of slip rings grew. This led to the progression from standard slip rings to through-hole slip rings, designed to handle concurrent channels such as wiring, pipes, or other hardware, through the center hole. Over the years, they have grown to accommodate diverse applications ranging from CCTV systems to wind turbines, showcasing their adaptability and innovation in overcoming technical challenges.

Standard of Through Hole Slip Ring

When discussing standards, it’s vital to note that these often reflect the electrical and safety requirements of the specific region or industry in which the slip ring is used. Slip rings should typically accord with the International Electrotechnical Commission’s IEC 60077-5, which states the requirements for slip ring assemblies for power and auxiliary circuits. Another important standard is IECEx, certifying slip rings for potentially explosive environments. Specific industries may also have additional standards that need to be met. Specifically, standards related to electrical safety, performance, and environmental influence are taken into account. These standards ensure quality, safety, and reliability in the design and operation of the slip ring.

Components of Through-Hole Slip Ring

What makes the through-hole slip ring? What makes you distinguish it from the other slip rings? The slip ring has two distinctive parts. The following are the parts that make a through-hole slip ring:

- The stationary part: It is the part that does not move. In most through-hole slip rings, it is of graphite or metallic brush. It is the one that is responsible for the transmission of power to the metallic ring while rotating.

- The rotating part: It is in the vacant space in the middle. The material, make, and what it transmits differs from the companies that manufacture the slip ring.

Through Hole Slip Ring Made of Material

The material selection of through-hole slip rings is similar to traditional slip rings. The ring components of slip rings, including those of the through-hole variant, are usually made of conductive metals, mainly copper, but also silver and gold for high-performance applications. Rarely can other metals be used such as brass or even aluminum. Brush material is primarily a function of desired life, environmental factors, and cost considerations. It ranges from carbon, metalized carbon, and silver graphite to precious metal wire brushes. By using tough materials such as stainless steel or aluminum, you can ensure that there is enough housing to protect the components. The housings of these components are usually made of aluminum or stainless steel and are able to withstand environmental influences and mechanical stress.

How to Make a Through Hole Slip Ring

The creation of a through-hole slip ring starts with a detailed analysis of application requirements. This would include the desired inner diameter, the number of circuits it needs to accommodate, the nature and magnitude of the signals or power to be transmitted, rotational speed, and more. Following the design phase, the precision manufacturing of the slip ring components begins, involving multiple stages such as raw material selection, machining, plating, assembly, and rigorous testing.

The manufacturing of a through-hole slip ring involves several steps including designing, selecting, and machining materials, assembly, and testing. The design is specific to the application and considers factors such as the dimensions of the hole, number of circuits, voltage, and current ratings. Once the components (rings and brushes) are fabricated, they are carefully assembled with adequate alignment. After assembly, the slip ring is put through several tests, such as electrical and noise tests, to ensure functionality and reliability.

How Does the Through-Hole Slip Ring Work?

As said earlier, the slip ring has extensive use. Many automotive devices that rotate 360 are using a through-hole slip ring to transfer power and signals from the rotating parts to stationary ones. To understand how the slip ring works, let’s look at the following:

- The mechanical part: The mechanical part is the equipment or device that you install the slip ring. It is the one responsible for housing the slip ring for it to work. The mechanical part support and enable the slip ring to function effectively. Kt also gives the slip ring grade, dimension, weight, and protection.

- The electrical part: According to many, it is the complicated part of the slip ring. It is the one responsible for the transmission of electric currents or the signals that you want to transfer. Due to its complication, everything at this part should be right as the electrical part. Manufacturers take time and are careful when making this part. The electrical is responsible for transferring and communicating between the channel or hole part and the fragile outer part.

So how does the slip ring work? Well, just like any other slip ring, after installation, the through-hole slip ring transfers signals and power when the brushes brush against the stationary as it rotates.

Different Types of Through Hole Slip Rings

The diverse categories of through-hole slip rings are often classified based on their bonding types that include:

- Capsule Through Hole Slip Rings: Compact and efficient, they are designed for transmitting signals and/or power. They are primarily used in CCTV systems, robotics, rotary sensors, and more.

- Large Diameter Through Hole Slip Rings: These cater to large industrial machinery that requires the passage of large cables, mechanical parts, or gas/liquid mediums through the central hole.

- Modular Through Hole Slip Rings: They provide customization flexibility and can be easily integrated with other rotary joints or devices requiring rotary transmission.

Each type is designed to cater to specific needs based on the overall system requirements to ensure optimal performance.

Why Through Hole Slip Ring Is Important

Today’s technology landscape demands increasingly advanced and versatile solutions that ensure seamless operation. Herein lies the pivotal role of through-hole slip rings. They are a significant enabler for systems requiring rotation along with the transmission of power and signals, like radar systems, CT scanners, wind turbines, and robotics, to mention a few.

Through-hole slip rings are critical because they allow for mechanical flexibility, ease of system assembly, and smoother operations. They not only facilitate the transmission of power and signals from stationary to revolving parts but also allow for the concurrent passage of other mechanical or fluid elements through the central hole. This enhances the functionality and adaptability of the system.

Through-Hole Slip Ring – the Applications

Where can you find the through-hole slip ring? Many electromechanical uses the slip ring. That is because of the advantages the slip ring brings in a machine, as you shall read below. The following are the uses of the through-hole slip ring:

- Loading and offloading: Have you ever been to a port? The workers at the port use machines to load and unload. Those machines have a through-hole skip ring in them. The devices include stakes, power plants, heavy mass lifters, and high-voltage machines. The slip ring is suitable for lifting heavy loads due to how it is capable of transmitting high voltage.

- Heavy motors in mining industries: In a mining firm, there are powerful machines that grind and break down different raw materials. The tools require a higher voltage, and that is why a through-hole comes in handy. It facilitates the transfer of power for devices and other automobiles to work in mining and cement companies.

- Electricity generators: Here, slip rings are used more. That is because most power plants have a lot of rotating parts that require a slip ring. The generator needs a slip ring that can transfer high voltage without any damage, and this is why the through-hole slip ring comes in handy. For example, wind turbines and windmills have through-hole slip rings to aid in the transfer of power and signal.

- Offshore cranes: When making cranes, different slip rings are placed in rotating parts to make the crane work efficiently without any limitations. One of the slip rings used the through-hole slip ring. Cranes are used in the construction industry to move materials from one place to another.

What Are the Characteristics of the Through Hole Slip Ring?

Their unique design allows these slip rings to handle any combination of power, signal, and data transmission while allowing other operational necessities to pass through their hole. They are celebrated for their compatibility with high rotational speeds, long operational life, low electrical noise, and reliable performance even in demanding operational environments.

- Are designed for long-life performance

- Exhibit low electrical and mechanical noise

- Accommodate high rotational speeds

- Show high levels of electrical and mechanical reliability

Advantages of Using the Through-Hole Slip Ring

- The slip ring can transfer both power and signal. It makes it convenient to use since you don’t have to have different channels to transfer both signals and power. That makes it comfortable to use in turbines, processing plants, and generators.

- Manufacturers use fiber tech to make the brushes in the through-hole slip ring. That makes the slip ring durable, and rust-free. It does not make noise while working. That overall reduces the cost of production since maintenance cost is low.

- This slip ring can stand the test of extreme weather conditions. That is because it is of good quality material that is resistant to wear, harsh weather conditions, and extremely high temperatures. That explains why slip rings are used in high-voltage power plants.

Where to Buy Through Hole Slip Ring

Most reliable manufacturers of slip rings have dedicated websites where you can get detailed product catalogs. You can also make use of online trade platforms like Alibaba, IndiaMART, and even global e-commerce platforms like eBay and Amazon. However, it is crucial to research quality certificates, customer reviews, and product specifications before purchase.

You can also purchase slip rings through our website. As a slip ring manufacturer established in 2011, we have a professional R&D team and production team.

Some Important Things About Through Hole Slip Ring

Through-hole slip rings are key components in many modern machinery and systems. When choosing a through-hole slip ring, it is important to assess parameters such as current/voltage requirements, rotational speed, required life cycle, the environment (temperature, dust, humidity), maintenance needs, and cost-effectiveness.

Frequently Asked Questions

Q: What exactly is a through-hole slip ring?

A: It’s a type of slip ring with a hole in its center, allowing for other mechanical elements or fluids to pass through.

Q: What are the applications of through-hole slip rings?

A: They’re used in many devices and systems requiring continuous rotation, such as wind turbines, medical imaging machines, cable reels, rotary tables, etc.

Q: How is the size of the through hole determined?

A: The size of the hole is typically determined by the system requirements, specifically the channels passing through the hole.

Q: What materials are used in the production of through-hole slip rings?

A: The rings often utilize metals with high electrical conductivity like copper, silver, or gold, while brushes are usually made from graphite or metal alloys.

Q: What maintenance is needed for through-hole slip rings?

A: Similar to traditional slip rings, they need periodic cleaning, inspection, and potential component replacement.

Q: How is a through-hole slip ring different from a standard slip ring?

A: The key difference lies in the central hole of the through-hole slip ring, which allows for the concurrent passage of other elements.

Q: Can a through-hole slip ring be customized?

A: Yes, vendors usually offer customizations depending on the specific requirements of the application.

Q: What factors should I consider when buying a through-hole slip ring?

A: Consider factors such as the dimensions of the hole, number of circuits, voltage and current rating, expected lifespan, and environmental conditions, among others.

Q: Are there different types of through-hole slip rings?

A: Yes, there are different types such as the capsule, large diameter, and modular through-hole slip rings.

Q: Can I use a normal slip ring in place of a through-hole slip ring?

A: It typically depends on the exact requirements of your system. If a central hole is necessary for other elements to pass through, a standard slip ring may not suffice.

Manufacturers are striving to make slip rings that suit all industrial purposes. One such slip ring is a through-hole slip ring. It is an electromechanical device that has a hole at the center and is used in high-voltage power plants, cranes, and heavy motors because of its advantages.

See What We Can Do