Delving into the realm of electromechanical devices, this article uncovers the complexities and functionalities of an integral component – the AC (Alternating Current) Slip Ring. For the uninitiated and the industry experts alike, this comprehensive guide offers an insight into its design, operation, and vital role played in diverse fields. A silent workhorse behind many systems, from weather-resistant wind turbines to advanced medical equipment, the AC Slip Ring facilitates uninterrupted power and signal transmission between stationary and rotating parts.

This all-inclusive guide enriches your understanding of AC Slip Rings, exploring their construction, working mechanisms, types, applications, and benefits. It also navigates through the associated challenges, providing crucial tips for installation, maintenance, and troubleshooting. Further, it glimpses into future trends and finally, distills common queries in a FAQ section, ensuring a complete understanding of this essential electromechanical marvel.

What Is an AC Slip Ring?

An AC Slip Ring is a sophisticated electromechanical device designed to transmit both power and electrical signals from a stationary to a rotating structure. Its configuration incorporates the use of ‘slip’ or ‘rotary’ interfaces, facilitating the connection, reduction of machine wear, and improvement of machine performance. More than a simple mechanical assembly, the AC Slip Ring, in reality, is a testament to years of scientific research and technological advancements, straddling the disciplines of physics, engineering, and materials science.

While AC Slip Rings may share their basic functionality with their DC counterparts, the separation lies in the details. The primary distinction is the type of current they are designed to handle. An AC Slip Ring manages the transmission of alternating current (AC), which changes its direction frequently. On the other hand, a DC Slip Ring is used for direct current (DC) transmission, where the current flows in a constant direction. The handling of high-frequency signals and efficient power transfer gives AC Slip Rings a distinctive edge, augmenting their importance in several hi-tech applications.

The multifaceted role of AC Slip Rings can be seen across a range of industries, reinforcing their importance in today’s world. From large-scale applications like power generation and transmission in wind turbines and cable reels as seen in the renewable energy sector to the microscopic precision required in medical imaging devices and radar antennas in the healthcare and defense industries respectively. The critical task of facilitating a seamless flow of power and data signals in moving parts is entrusted with AC Slip Rings. As rotating applications continue to ascend in complexity and variety, the utility and importance of AC Slip Rings follow suit, molding them into an indispensable part of modern machinery and systems.

What Is an AC Slip Ring Made of?

Diving beneath the surface into the construction of an AC Slip Ring, one can uncover the meticulously chosen materials that shape this electromechanical device. The fundamental components of any AC Slip Ring are the ring itself and the brushes that maintain the electrical connection. Metals such as brass, copper, or even gold are often employed to craft the rings due to their excellent electrical conductivity. Similarly, the brushes are composed of precious or semi-precious materials like silver graphite or gold wire, chosen specifically for their robust conductivity and low friction characteristics.

The careful selection of these materials doesn’t happen by chance but is a result of deliberate design decisions based on the properties required for successful operation. Key factors such as electrical conductivity, durability, resistance to corrosion, and the generation of minimal dust and debris during operation play significant roles in what materials are chosen for the construction of these rings and brushes. Electrical conductivity is pivotal for efficient power and signal transmission, while durability ensures the device can weather the wear and tear of continuous operation, thereby extending the device’s lifespan.

The implications of such careful material selection are evident in the durability and reliability of AC Slip Rings. High conductivity metals ensure smooth, efficient signal transmission even under constant use, while low friction materials minimize wear, reducing the frequency of replacements and system downtimes. This in turn promotes longevity and maintains system integrity, making AC Slip Rings a reliable choice for various critical applications in diverse industries. In effect, the heart of an AC Slip Ring’s performance and reliability lies nestled within the materials used in its construction, thus underscoring their careful selection as a hallmark of quality, practical design, and foresight.

How Does an AC Slip Ring Work?

Delving into the operational intricacies of an AC Slip Ring, we begin by examining its primary purpose, which is the seamless transmission of power and electrical signals from a stationary component to a rotating one, or vice versa. Crucial in countless applications with moving parts, the AC Slip Ring is an electromechanical device that leverages the principles of physics and engineering to bridge the gap between still and moving components.

Stepping progressively into the details of the working process, the AC Slip Ring’s configuration consists of two key elements—the rings and the brushes. The rings, radially aligned around the rotating core, are electrically connected to the current-carrying conductors embedded within the stationary section. As the apparatus rotates, the brushes, also connected to different conductors, slide and maintain unwavering contact with the rings, ensuring the unbroken electrical connection between the stationary and rotating parts. This generates a continuous flow of electrical current and signal transmission despite the continuous movement across the components.

Examining the primary components and their functions, we first encounter the rings, composed of metals with excellent electrical conductivity. They serve as the primary conductive element, allowing electrical current and signals to traverse effortlessly. The brushes, crafted from precious or semi-precious materials, maintain contact with the rings during the rotating motion. For optimal performance, these brushes are designed to possess not only excellent conductivity but also low friction, minimizing wear and maximizing durability. Together, these elements form the mechanism of the AC Slip Ring, empowering it to maintain the electrical connection even amidst constant rotation, thus ensuring uninterrupted power and signal transmission in a host of applications.

Through the contextual understanding of the AC Slip Ring’s operation and its primary components, it becomes apparent that attention to detail, material selection, and engineering ingenuity define the seamless functionality of this electromechanical device.

Types of AC Slip Rings

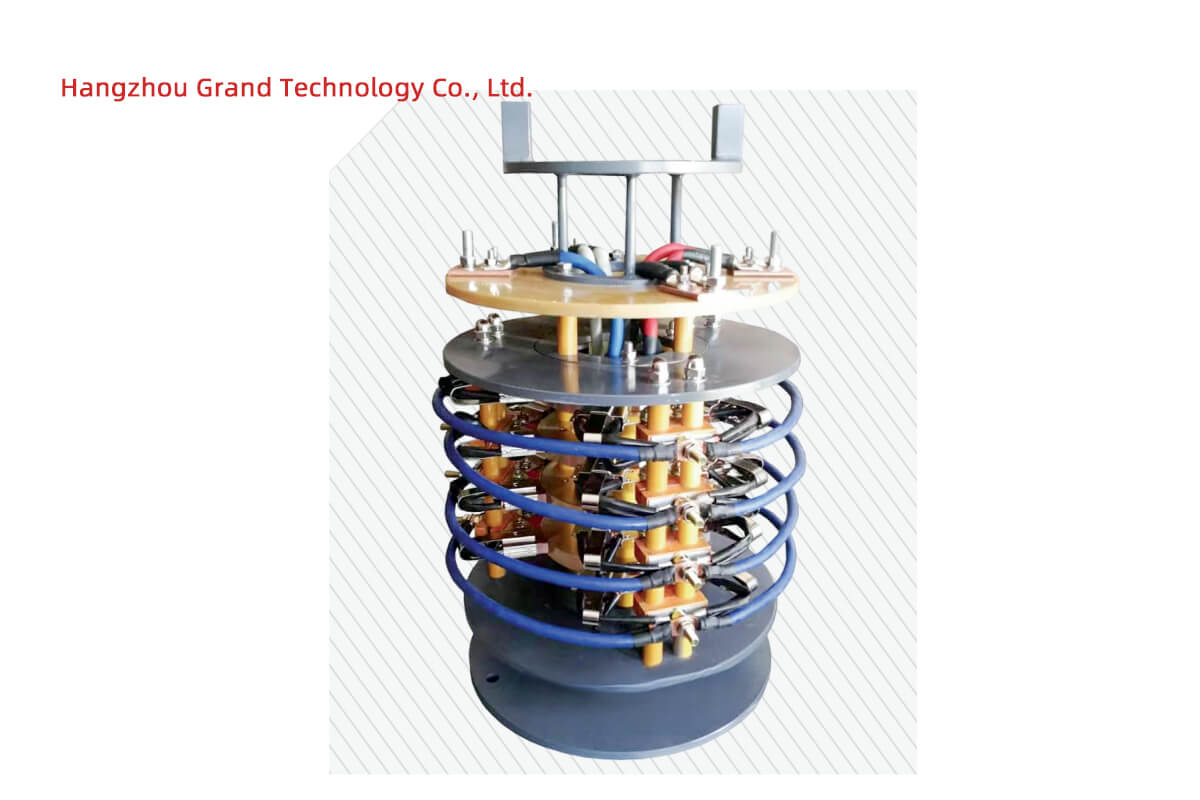

Just as applications and requirements vary from one field to another, AC Slip Rings also come in a variety of types to cater to these diverse needs. These variants range from simple designs to sophisticated, customized applications; each bringing its own unique set of features and advantages.

The most common types include Pancake Slip Rings – characterized by their flat, disc-like shape where the rings are arranged in concentric circles;

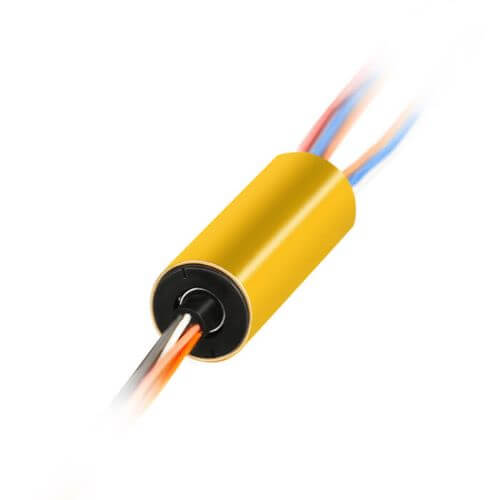

Capsule Slip Rings – compact in design, widely used in data transmission systems;

Through Hole Slip Rings– these feature a hole in the middle to facilitate additional installations;

and Mercury Wetted Slip Rings – where the brushes are replaced with liquid mercury for higher conductivity and minimal wear and tear.

A comparative analysis reveals significant differences between these types. Pancake Slip Rings, with their flat shape, are ideal for installations with minimal axial height but larger diameter. Capsule Slip Rings, on the other hand, are perfectly suited for compact spaces and provide reliable signal transmission. Through Hole Slip Rings are highly versatile and easily incorporated into existing mechanisms, while Mercury Wetted Slip Rings promise high precision, and low electrical noise but require utmost safety precautions due to their use of liquid mercury.

Choosing the right type of AC Slip Ring for an application comes down to a careful evaluation of needs and constraints. For instance, if the application requires low axial height, Pancake Slip Rings might be the best choice. In the case of compact spaces, Capsule Slip Rings might be more appropriate, while high-precision tasks might lean towards Mercury Wetted Slip Rings. Through these examples, we can appreciate how the selection of the correct type of AC Slip Ring has a direct implication on the efficiency and effectiveness of the rotating systems they are implemented.

What Are the Applications of AC Slip Rings?

AC Slip Rings find use in a broad spectrum of applications, owing to their unique ability to facilitate uninterrupted power and signal transmission across moving parts. Their flexible design and versatility enable them to cater to a gamut of technical requirements across various industrial domains.

Venturing into specifics, let’s explore its far-reaching implications in different industries.

- Renewable Energy: AC Slip Rings are one of the vital components in wind turbines. They ensure smooth electrical connection, power transmission, and data communication between the turbine’s stationary and rotating parts.

- Military and Defence: In hi-tech radar systems and remotely operated vehicles (ROVs), AC Slip Rings support the seamless transmission of vital signals and data across rotating platforms.

- Healthcare: They are central to the operation of medical imaging equipment like MRI and CT scanners where the device parts rotate to capture comprehensive images while requiring uninterrupted power.

- Industrial Applications: In applications like cable reels, AC Slip Rings ensure the continuous transfer of electric power and communication signals from stationary to rotating parts.

To illustrate with real-world examples, the viability of wind turbines for power generation often relies on AC Slip Rings for transmitting power from the moving blades to the grid, while ensuring constant data transmission for monitoring and automation. Similarly, the precision and reliability of images produced by an MRI scanner essentially depend on the seamless operation of AC Slip Rings in managing power and signal transmission amongst moving parts.

Through these implementations across various industries, the vital role AC Slip Rings play in the proper functioning of numerous critical applications comes to the fore, spotlighting its importance and versatility.

What Are the Benefits of Using an AC Slip Ring?

The application of AC Slip Rings seeks to bring an array of benefits to the table, enhancing the operational efficiency and durability of the systems they’re incorporated into.

A few major benefits include:

- Uninterrupted Signal and Power Transmission: Perhaps the most significant advantage of an AC Slip Ring is facilitating continuous power and signal transmission between stationary and rotating parts of a system, effectively bridging the disconnect that can occur due to rotation or movement.

- Durability: The materials used in constructing AC Slip Rings are selected for their high conductivity and low wear properties, resulting in a robust and hard-wearing device that can withstand the demands of continuous operation.

- Versatility: AC Slip Rings can be custom-designed to meet specific requirements of varying applications and industries. This includes crafting slip rings to cater to a range of sizes, power requirements, and signal types.

When compared to other similar technologies such as wireless solutions, AC Slip Rings provide a more stable and reliable connection, unaffected by interferences. Also, unlike mechanical commutators that can wear out due to sparking, AC Slip Rings ensure a smooth, spark-free transmission, thereby ensuring safety and reducing maintenance needs.

As far as user concerns are related to these benefits, it’s essential to remember that while AC Slip Rings do offer many advantages, their performance and benefits depend heavily on their adequate installation and maintenance. For example, installation should ensure proper alignment to avoid undue wear and tear, and routine checks should be performed to ensure the device is functioning optimally. Thus, a rightly maintained AC Slip Ring can bring a host of benefits to a rotating system, enhancing its overall performance and longevity.

Challenges and Limitations of AC Slip Rings

Despite the numerous advantages of AC Slip Rings, they also come with their own set of challenges and limitations, which users should be aware of to ensure optimal operation and extended service life.

A brief outline of associated challenges highlights issues like the need for periodic maintenance, the potential for wear and tear due to continuous operation, the risk of degradation in environments with extensive dust or moisture, and the inherent complexity involved in the installation and integration of AC Slip Rings into existing systems.

Delving into limitations, one of the principal concerns is the physical wear that occurs due to the constant contact between the brushes and rings. This not only requires regular maintenance and potential replacement of the brushes but also impacts system efficiency. Another significant limitation is the noise and potential signal distortions caused by continuous contact, especially at high rotation speeds or when transmitting sensitive data signals. Lastly, despite their incredible versatility, standard AC Slip Rings might not be suitable for some specific applications requiring high-frequency transmission or handling of unique signal types.

Addressing these challenges and limitations requires a multi-faceted approach. Installing high-quality AC Slip Rings can reduce wear and tear, while regular maintenance checks can ensure they are in good operating condition. Employing brushless designs or adopting newer technologies like fiber optic rotary joints may alleviate some limitations related to high-frequency signal transmission.

In a nutshell, being aware of the potential challenges and limitations associated with AC Slip Rings, and the ways to overcome them, can help users extract the maximum utility from these devices through optimal performance and longevity.

Installation and Maintenance Tips for AC Slip Rings

Ensuring optimal performance from an AC Slip Ring encompasses not only its manufacturing process but also the installation and maintenance procedures.

Installation:

- Read the Manual: Begin by thoroughly reading the user manual to familiarize yourself with the specific model of the AC Slip Ring to be installed.

- Ensure Alignment: Proper alignment is critical during installation. Misalignment can lead to excessive wear and tear.

- Connect Properly: Correctly connect the power and signal lines as per instructions. Incorrect connections may cause malfunction or even damage.

- Verify Installation: After installation, conduct a dry run to confirm that the AC Slip Ring is functioning as expected.

Maintenance:

Proactive maintenance not only extends the life of an AC Slip Ring but also enhances its operational efficiency.

- Routine Check: Regular inspection of brushes and rings can help identify wear and tear early, allowing timely replacement.

- Clean Environment: Working in a clean, dust-free environment could reduce potential abrasive wear.

- Lubrication: Some AC Slip Rings may benefit from periodic lubrication to reduce friction.

Troubleshooting:

Familiarizing oneself with common issues and their solutions can save time and avoid unnecessary downtime.

- Intermittent Signal: If there’s an intermittent signal, check for wear or inadequate pressure on brushes.

- Noise: Noise can be a result of scratches on the rings or dust on the brushes. Thorough cleaning may resolve the issue.

- Reduced Efficiency: This might be due to the aging of components, demanding attention for a parts review and perhaps replacement.

In conclusion, adopting these installation and maintenance tips can yield dividends in the form of the extended lifetime and superior performance of AC Slip Rings.

Future Developments and Market Trends for AC Slip Rings

The world of AC Slip Rings is one of constant evolution, shaped by emerging trends and future developments heavily influenced by technological advancements and changing industrial needs.

Current Market Trends:

At present, the key market trends show a growing inclination towards compact and reliable slip rings. There’s a surge in demand for modular slip rings that can easily integrate with existing systems. Also, the rising importance of renewable energy sources, especially wind power, has amplified the demand for high-quality AC Slip Rings.

Future Developments:

Looking forward, the industry is likely to witness significant technological enhancements. The focus is likely to shift towards brushless designs, increasing longevity and reducing maintenance requirements. Advancements in material science may yield slip rings capable of withstanding higher speeds and temperatures.

The integration of digital technologies is another potential area of development. IoT-enabled AC Slip Rings could provide real-time valuable insights into wear and tear, preemptive maintenance alerts, and increased system automation.

Technological Impact:

Technological advancements have a massive impact on the future of AC Slip Rings. Incorporation of nanotechnology might refine the conductive properties of Slip Rings, enhancing their data transmission capabilities. Developments in AI and Machine Learning can optimize the operation of AC Slip Rings – increasing efficiency, reducing interference, and foreseeing maintenance needs.

To wrap up, the AC Slip Rings industry is poised for significant expansion and evolution, driven by a blend of market dynamics, customer needs, and technological advancements. This progression will likely aid in overcoming existing limitations while expanding the applicability of this crucial technology.

Conclusion

AC Slip Rings have a broad spectrum of applications and benefits, showcasing their importance in the industrial landscape. Comprehensive understanding leads to optimal usage and capitalizes on its vast potential.

FAQs about AC Slip Rings

This section addresses a compilation of frequently asked questions related to AC Slip Rings and dispels common misconceptions about them.

Q1. What is the main function of an AC Slip Ring?

A: The primary function of an AC Slip Ring is to deliver uninterrupted transfer of electrical power and signals between stationary and rotating parts within a system.

Q2. How do AC Slip Rings differ from other types of Slip Rings like commutators?

A: AC Slip Rings are designed to transmit both AC and DC electrical power and signals, while commutators are geared towards transmitting just DC electrical power.

Q3. Can AC Slip Rings be used for data and signal transmission?

A: Absolutely! AC Slip Rings can effectively transmit analog, digital, video, and Ethernet data and signals between stationary and rotating components.

Q4. Can wireless connections replace AC Slip Rings?

A: While wireless connections can facilitate the transfer of data and signals without physical interaction, they often face issues with interference and range limitations. Thus, AC Slip Rings providing stable and continuous connections are ideal for safe data signal and power transmission.

Q5. Are Slip Rings incapable of custom adaptations as per specific requirements?

A: Contrary to this belief, many Slip Ring manufacturers create custom designs to cater to specific requirements across different applications.

Q6. Do AC Slip Rings always produce sparks when in operation?

A: Sparks typically occur in outdated or poorly kept Slip Rings. Modern, well-maintained AC Slip Rings can maintain spark-free contacts, ensuring steadiness during operation.

See What We Can Do