In the realm of marine exploration, few innovations have proven as transformative as Remotely Operated Vehicles (ROVs). These unmanned submersibles have emerged as indispensable tools across a spectrum of industries, including offshore oil and gas, marine research, and underwater inspections. ROVs are the unsung heroes of underwater missions, enabling humans to venture into the depths where the crushing pressure, frigid temperatures, and total darkness render conventional exploration methods impractical or even impossible.

However, the successful operation of ROVs hinges on a delicate interplay of intricate components and systems. While their maneuverability, cameras, and propulsion mechanisms are readily acknowledged for their contributions, one often-overlooked element holds a pivotal role in the ROV’s functionality – the humble slip ring.

In this comprehensive guide, we will embark on a journey deep into the heart of marine ROV system slip rings. Our exploration will take us through various aspects, unraveling the intricacies of these unassuming yet critical components. We will address the significance of slip rings in the world of underwater exploration, elucidate the mechanics behind their operation, and provide valuable insights into their selection, installation, and maintenance.

Moreover, we will delve into the diverse types of slip rings that cater to specific ROV needs and present real-world case studies to showcase their practical applications. Stay tuned as we also uncover the latest trends and future developments in slip ring technology, equipping you with the knowledge to make informed decisions when choosing slip rings for your ROV system.

Now, let’s plunge into the depths of knowledge about marine ROV system slip rings and unlock the secrets that empower these remarkable underwater explorers.

What Is Marine Rov System Slip Ring?

Defining ROVs and Their Applications in Marine Industries

To truly appreciate the significance of marine ROV system slip rings, it’s imperative to first gain a comprehensive understanding of what ROVs are and the pivotal roles they play in diverse marine industries.

Remotely Operated Vehicles, or ROVs, represent the technological epitome of underwater exploration and intervention. These ingenious machines, often resembling compact submarines, are purpose-built to withstand the hostile and unforgiving conditions found beneath the ocean’s surface. They are the mechanical extensions of human curiosity, enabling us to venture into the deep-sea abyss and conduct a wide array of tasks with precision and efficiency.

ROVs find their calling in a multitude of marine industries. In offshore oil and gas operations, they are deployed for tasks such as pipeline inspections, subsea equipment maintenance, and drilling support. In the field of marine research, ROVs allow scientists to study ocean ecosystems, explore geological formations, and retrieve samples from the depths. They are also indispensable for underwater archaeology, salvage operations, and environmental monitoring. The applications are as diverse as the ocean itself.

Explaining the Components and Systems that Make Up an ROV

The complexity of ROVs lies not only in their missions but also in their internal architecture. These high-tech submersibles are equipped with a symphony of components and systems that work in harmony to ensure their functionality.

At the heart of an ROV is its power source, typically an array of batteries or, in some cases, a tethered power supply from the surface vessel. Propulsion systems, often comprising thrusters, enable precise maneuverability and navigation through the water column. Cameras and sensors provide the ROV’s “eyes” and “ears,” relaying vital visual and environmental data to the operators above. Manipulator arms, equipped with various tools, extend the ROV’s reach for tasks like sample collection or equipment manipulation.

Emphasizing the Importance of Reliable Electrical Connections in ROV Systems

Within this intricate web of systems and components, the thread that holds it all together is reliable electrical connections. Without seamless electrical communication, the ROV would be rendered inert, blind, and impotent in the ocean’s depths.

Imagine an ROV tasked with inspecting a deep-sea pipeline or conducting a scientific survey. It relies on real-time data transmission to guide its movements, capture images, and relay critical information back to operators aboard the surface vessel. The loss of electrical connectivity in such scenarios is not merely an inconvenience but a potential disaster.

In this context, marine ROV system slip rings emerge as the unsung heroes of underwater exploration. These unassuming components bridge the gap between the stationary vessel and the agile ROV, ensuring a continuous flow of electrical power, signals, and data. Slip rings are the guardians of uninterrupted operations, and their significance cannot be overstated.

The Crucial Role of Slip Rings in ROV Systems

Slip rings are ingenious devices that facilitate continuous electrical connections in rotating systems. In essence, they allow electrical power, signals, and data to be transmitted between stationary and rotating parts of a machine. We’ll delve into the mechanics of slip rings and how they’re vital for maintaining seamless communication within ROV systems.

Before we dive into the intricacies of marine ROV system slip rings, it’s essential to understand the unique demands these vehicles face beneath the waves. ROVs are tethered to the surface by cables, which serve as lifelines, carrying both power and data to and from the depths. Yet, as these agile machines explore the ocean’s mysteries, they twist, turn, and pivot in all directions. The cables must follow suit, spiraling and unwinding without hesitation.

This is where slip rings come into play. Slip rings are ingenious devices that serve as the unsung heroes of the ROV world. They are the guardians of continuous electrical connections in the midst of this mechanical ballet. Slip rings allow electrical power, signals, and data to flow seamlessly between the stationary and rotating parts of the ROV, ensuring that vital functions like camera operation, data transmission, and even the ROV’s power source are maintained without interruption.

In the following sections, we will delve deeper into the mechanics and significance of slip rings, exploring their various types, installation, maintenance, and their pivotal role in enabling ROVs to fulfill their missions beneath the waves.

The Role of Slip Rings in Marine ROVs

Detailing Why Slip Rings are Crucial in ROV Applications

To grasp the full significance of slip rings in marine ROV systems, one must dive into the heart of their operational challenges. Imagine an ROV exploring the ocean’s depths, tasked with meticulously inspecting a subsea pipeline or investigating an archaeological site miles beneath the surface. In these high-pressure, low-visibility environments, the ROV’s ability to function seamlessly is nothing short of miraculous.

Crucial to this functionality is the continuous exchange of information and power between the stationary surface vessel and the dynamic ROV below. This is where slip rings step onto the stage as indispensable components. Unlike traditional electrical connectors, which would inevitably twist and tangle, slip rings enable the seamless transmission of electrical signals, data, and power even as the ROV performs its intricate underwater ballet.

Without slip rings, ROV missions would be fraught with interruptions and complications, potentially compromising safety and data integrity. Slip rings serve as the vital conduits that bridge the physical gap between the static world above and the dynamic realm below the waves.

Discussing How Slip Rings Enable Data and Power Transmission in Underwater Environments

The role of slip rings becomes all the more profound when one considers the formidable challenges of underwater data and power transmission. The subaquatic realm is a hostile environment, characterized by extreme pressure, corrosive saltwater, and minimal visibility. Traditional electrical connectors, if used, would quickly succumb to these harsh conditions, leading to costly and potentially catastrophic mission failures.

Slip rings, however, are engineered to thrive in this aquatic arena. They are designed with materials and construction techniques that resist corrosion and maintain their performance under pressure. Moreover, slip rings enable the seamless transfer of critical data and power, allowing ROVs to carry out their missions with precision and efficiency.

In the murky depths, where visual feedback is often the sole means of navigation and data collection, the importance of uninterrupted electrical connections cannot be overstated. Slip rings facilitate the real-time transmission of high-definition video feeds, environmental sensor data, and control signals, ensuring that operators on the surface vessel have a clear window into the underwater world.

Highlighting the Challenges of Maintaining Electrical Connections in Underwater ROVs

Underwater ROVs face a unique set of challenges that demand robust solutions. Traditional electrical connectors and cables, which are suitable for land-based applications, are ill-equipped to handle the dynamic, corrosive, and high-pressure conditions of the ocean’s depths.

For instance, the continuous rotation, tilting, and panning of an ROV’s camera system could cause ordinary cables to twist and fray, resulting in signal degradation or loss. Similarly, the corrosive effects of saltwater can swiftly degrade electrical contacts, leading to unreliable connections and, potentially, mission failures.

Slip rings rise to the occasion by offering a reliable, low-maintenance solution to these challenges. By providing a constant electrical pathway between the ROV and the surface vessel, they eliminate the need for cables that could twist or break. Moreover, their corrosion-resistant design ensures that they can withstand prolonged exposure to saltwater, maintaining the integrity of the electrical connections.

In essence, slip rings are the linchpin that enables underwater ROVs to overcome the formidable challenges of their operating environment. They ensure that these remarkable machines can operate with precision and reliability, conducting critical tasks and gathering valuable data from the darkest and most inaccessible corners of the ocean. In the subsequent sections, we will delve deeper into the intricacies of slip rings, exploring their types, installation, maintenance, and practical applications in the world of marine exploration.

Key Features to Look for in Marine ROV System Slip Rings

Describing the Essential Attributes of Slip Rings Suitable for Marine ROV Systems

As we embark on our exploration of marine ROV system slip rings, it’s imperative to understand the critical attributes that make these components suitable for the demanding world of underwater robotics. The choice of slip rings is not arbitrary; it directly impacts the performance and reliability of an ROV’s electrical connections in the harsh subaquatic environment.

Factors like Corrosion Resistance, Durability, and Precision

First and foremost, slip rings for marine ROV systems must exhibit exceptional corrosion resistance. The corrosive effects of saltwater are relentless, and any vulnerability in the slip ring’s construction could lead to premature failure. Slip rings engineered for the marine environment employ materials and coatings that can withstand prolonged exposure to saltwater without compromising their performance.

Durability is another paramount consideration. ROVs are subjected to rigorous missions that may involve contact with underwater structures, harsh currents, and turbulent conditions. Slip rings must be built to withstand physical stresses and shocks without succumbing to damage.

Precision is equally crucial. ROVs rely on highly accurate data transmission for tasks such as inspecting subsea equipment or collecting scientific data. Slip rings must maintain signal integrity and minimize signal loss to ensure that the data transmitted between the ROV and the surface vessel is both accurate and timely.

Providing Information on IP Ratings and Material Selection

To assist in selecting the most appropriate slip rings for marine ROV systems, it’s essential to delve into the world of IP (Ingress Protection) ratings and material selection.

IP ratings classify the degree of protection a slip ring offers against intrusion by dust and moisture. In the context of marine ROVs, slip rings with high IP ratings are preferred as they provide an additional layer of defense against the ingress of salt water and particulate matter. This protection ensures the slip rings continue to function optimally in the challenging underwater environment.

Material selection plays a pivotal role in the longevity and performance of slip rings. Marine ROV system slip rings are typically crafted from materials such as stainless steel, bronze, or specialized alloys. Each material offers specific advantages in terms of corrosion resistance and durability. Understanding the advantages and limitations of each material helps ROV operators make informed decisions when selecting slip rings tailored to their operational requirements.

In summary, the selection of slip rings for marine ROV systems is a critical decision that hinges on several key attributes. Slip rings must exhibit corrosion resistance, durability, and precision to ensure reliable electrical connections in challenging underwater conditions. Additionally, understanding IP ratings and material options empowers ROV operators to make choices that align with their specific needs, ensuring the seamless functionality of these vital components in the unforgiving depths of the ocean. In the upcoming sections, we will delve further into the types of slip rings suitable for marine ROVs and explore their installation, maintenance, and practical applications.

Types of Slip Rings for Marine ROVs

In the intricate realm of marine ROV system slip rings, one encounters a diverse array of options, each tailored to specific operational requirements and environmental challenges. To make informed decisions when selecting slip rings for your underwater explorations, it’s crucial to delve into the world of slip ring types.

Comparing and Contrasting Capsule Slip Rings, Through-Bore Slip Rings, and Pancake Slip Rings

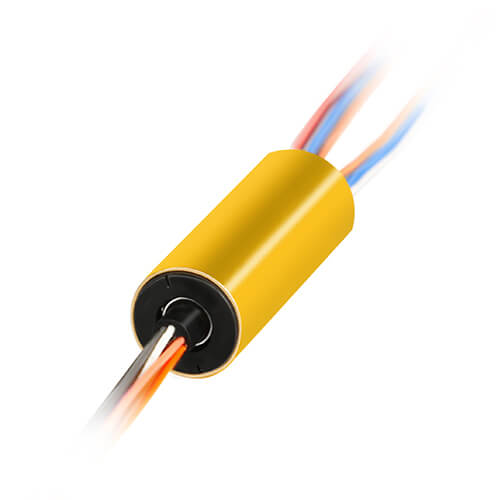

Capsule Slip Rings

These compact and cylindrical slip rings are a popular choice in marine ROV systems due to their space-efficient design. Capsule slip rings are ideal for applications where space is limited and the need for continuous electrical connections is paramount. They are known for their robustness and ability to withstand harsh underwater conditions. Capsule slip rings are often employed in ROVs for their reliability and resistance to corrosion, making them a dependable choice for mission-critical tasks.

Through-Bore Slip Rings

Through-bore slip rings are characterized by their central hollow core, allowing the passage of cables or other elements through the slip ring itself. This feature is particularly valuable in ROV systems where cable management is essential. Through-bore slip rings excel when there is a need to transfer not only electrical signals but also hydraulic or pneumatic lines through the same assembly. This versatility makes them a valuable asset in ROVs with complex mission requirements.

Pancake Slip Rings

Pancake slip rings, as the name suggests, are flat and compact, making them suitable for applications with space constraints. They are often used in ROVs where size and weight limitations must be considered. Despite their compact design, pancake slip rings deliver impressive performance and reliability. Their low-profile construction allows them to be seamlessly integrated into the ROV’s existing structure without impeding its maneuverability.

Explaining When to Use Each Type Based on Specific ROV Requirements

Selecting the appropriate slip ring type for your marine ROV system hinges on the unique demands of your underwater missions. Here’s a guideline on when to use each type:

– Capsule Slip Rings: Opt for capsule slip rings when reliability, corrosion resistance, and robustness are top priorities. These slip rings excel in harsh underwater environments and are well-suited for tasks where space may be limited, but a dependable electrical connection is non-negotiable.

– Through-Bore Slip Rings: Choose through-bore slip rings when your ROV missions demand versatility. If you require the simultaneous transfer of electrical signals, hydraulic or pneumatic lines, or any combination thereof, these slip rings offer the flexibility and space-saving advantages necessary for complex underwater tasks.

– Pancake Slip Rings: When space constraints or weight considerations are paramount, pancake slip rings are the go-to choice. Their low-profile design allows for seamless integration into compact ROV systems without compromising performance. They are an excellent option for ROVs that require unobtrusive yet reliable electrical connections.

In essence, the selection of slip ring types for marine ROV systems is a nuanced decision that hinges on the specific requirements of your underwater missions. By understanding the strengths and capabilities of each type, you can tailor your choice to ensure the optimal performance of your ROV in the challenging and dynamic underwater world. In the upcoming sections, we will delve further into slip ring installation, maintenance, and real-world case studies to shed light on their practical applications in the field of marine exploration.

Marine ROV System Slip Rings: Installation and Maintenance

Offering a Step-by-Step Guide on How to Install Slip Rings in an ROV System

The successful integration of slip rings into an ROV system is a critical step in ensuring seamless and uninterrupted underwater operations. Let’s embark on a step-by-step journey through the installation process, shedding light on the intricacies of this crucial task.

- Assessment of Requirements

Begin by comprehensively assessing your ROV’s requirements. Determine the number of slip rings needed, their types (capsule, through-bore, or pancake), and their specific functions within the system. Understanding these requirements is the cornerstone of a successful installation.

- Positioning

Carefully select the optimal location for the slip rings within the ROV. Consider factors such as accessibility, cable routing, and proximity to the devices or systems that will interface with the slip rings. This positioning should strike a balance between ease of maintenance and minimizing interference with other components.

- Cable Routing

Plan the routing of cables that will connect to the slip rings. Ensure that the cables are neatly organized and secured to prevent entanglement or damage during operation. Pay attention to strain relief techniques to safeguard against cable wear and tear.

- Mounting

Securely mount the slip rings in their designated positions, ensuring that they are firmly anchored to prevent vibrations or displacement during operation. Follow the manufacturer’s guidelines for the specific slip ring model to achieve proper mounting.

- Electrical Connections

Connect the cables to the slip rings according to the manufacturer’s instructions. Take care to maintain the correct polarity and ensure that connections are snugly tightened to prevent signal loss or electrical disruptions.

- Testing

Before finalizing the installation, perform comprehensive testing to confirm that all connections are functional. Test data transmission, power delivery, and any other signals passing through the slip rings. Identify and rectify any issues that arise during testing.

Have specific requirements for your Marine Slip Rings? Share your details in the form below, and we’ll tailor our solutions to meet your needs.

Providing Maintenance Tips to Ensure the Longevity and Performance of Slip Rings

Slip rings are designed to endure the challenging conditions of marine ROV missions, but they are not impervious to wear and tear. Regular maintenance is essential to ensure their longevity and optimal performance. Here are some key maintenance tips:

- Scheduled Inspections

Implement a routine inspection schedule to assess the condition of the slip rings. Regular visual inspections can identify early signs of wear, corrosion, or damage.

- Cleaning

Keep slip rings clean and free from debris or contaminants that can accumulate over time. Use manufacturer-recommended cleaning methods and materials to prevent damage to sensitive components.

- Lubrication

If the slip rings require lubrication, follow the manufacturer’s recommendations for the type and frequency of lubrication. Proper lubrication helps reduce friction and extends the slip ring’s lifespan.

- Tightening

Periodically check the tightness of electrical connections. Loose connections can lead to signal loss and should be tightened as needed.

- Discussing Common Issues and Troubleshooting Methods

Despite proactive maintenance, slip rings may encounter issues during operation. Familiarize yourself with common problems and troubleshooting methods:

- Signal Degradation

If you experience signal degradation, inspect the slip rings for corrosion or contamination. Clean or replace them as necessary.

- Intermittent Connections

Intermittent connections can be caused by loose cables or damaged connectors. Ensure all connections are secure and inspect cables for wear.

- Electrical Noise

Electrical noise can disrupt data transmission. Shielding and proper grounding can help mitigate this issue.

- Mechanical Damage

If slip rings sustain physical damage, they may need to be replaced. Regular inspections can help identify potential issues before they escalate.

By following these installation and maintenance guidelines and being prepared to address common issues, you can ensure the reliability and longevity of slip rings in your marine ROV system. In the subsequent sections, we will delve into real-world case studies to showcase the practical applications of slip rings in marine exploration and examine emerging trends in slip ring technology.

Marine ROV System Slip Rings: Case Studies

Presenting Real-World Examples of Marine ROV Systems and Their Slip Ring Setups

In the dynamic world of marine exploration, where every mission is a unique and complex endeavor, there is no better way to comprehend the importance of slip rings than through real-world case studies. These tangible examples shed light on how slip ring technology plays a pivotal role in the success of marine ROV systems.

Highlighting Success Stories and Challenges Overcome with the Right Slip Ring Technology

- Pipeline Inspection in Harsh Environments

Imagine an offshore oil and gas operation tasked with inspecting a critical subsea pipeline buried deep beneath the ocean floor. The harsh conditions, including corrosive saltwater and challenging currents, make this mission particularly demanding. In such scenarios, ROVs equipped with corrosion-resistant slip rings prove to be the heroes of the day. These slip rings maintain reliable electrical connections throughout the inspection process, enabling operators to remotely assess the pipeline’s integrity and make informed decisions regarding maintenance or repair.

- Scientific Exploration of Deep-Sea Ecosystems

Marine scientists embark on missions to study deep-sea ecosystems, striving to unlock the mysteries of life in the ocean’s abyss. ROVs equipped with precision slip rings play a vital role in these endeavors. High-definition cameras and sensors mounted on the ROV transmit invaluable data to researchers aboard the surface vessel. The reliability and precision of slip rings ensure that every detail, from the behavior of bioluminescent creatures to the composition of hydrothermal vent plumes, is captured without interruption.

- Salvage Operations in Treacherous Waters

Salvage operations in tumultuous underwater environments present formidable challenges. ROVs are deployed to locate, assess, and recover valuable assets or wreckage. The right slip ring technology enables these ROVs to effectively manipulate equipment, gather crucial data, and execute precise maneuvers despite strong currents and limited visibility. Success stories in salvage operations are often intertwined with the seamless functionality of slip rings.

- Environmental Monitoring in Remote Ocean Regions

Monitoring the health of remote ocean regions is essential for understanding the impact of climate change and human activity on marine ecosystems. ROVs equipped with advanced slip rings enable scientists to deploy a wide array of sensors and instruments to collect data on temperature, salinity, and biological diversity. The uninterrupted data transmission facilitated by slip rings is instrumental in long-term environmental studies.

These case studies underscore the versatile and indispensable role of slip ring technology in diverse marine ROV applications. They exemplify how the right slip ring setup can lead to success in challenging missions and provide valuable insights for future endeavors. As we proceed, we will explore emerging trends and innovations in slip ring technology, ensuring that marine exploration continues to push the boundaries of discovery in the depths of our oceans.

Marine ROV System Slip Rings: Emerging Trends and Future Developments

Discussing the Latest Innovations in Slip Ring Technology for Marine ROVs

In the ever-evolving world of marine ROV systems, staying at the forefront of technological advancements is crucial. In this section, we delve into the latest innovations in slip ring technology, which are shaping the future of underwater exploration. These developments are not only enhancing the capabilities of ROVs but also expanding the horizons of what can be achieved beneath the waves.

- Miniaturization and Weight Reduction: One notable trend is the ongoing miniaturization and weight reduction of slip rings. As ROVs become more agile and versatile, the demand for compact slip rings that occupy minimal space has grown. Miniaturized slip rings maintain the same level of reliability while allowing for greater maneuverability and payload capacity.

- Increased Data Transmission: With the growing importance of data collection in marine research and industry applications, slip ring technology has evolved to accommodate increased data transmission rates. High-speed slip rings now facilitate the transfer of large datasets in real time, enabling ROVs to capture high-resolution imagery, conduct advanced sonar surveys, and gather extensive scientific data.

- Enhanced Materials and Coatings: Corrosion remains a primary concern in marine environments. Recent advancements in slip ring materials and coatings have improved corrosion resistance. Slip rings are now better equipped to withstand extended exposure to saltwater, reducing maintenance requirements and enhancing overall reliability.

- Integrated Electronics: Emerging slip ring designs feature integrated electronics that monitor the performance of the slip ring in real time. These intelligent slip rings can detect issues such as signal degradation or wear and proactively provide alerts to operators. This predictive maintenance capability reduces downtime and maintenance costs.

Mentioning Potential Advancements and Their Impact on Underwater Exploration

The future of slip ring technology for marine ROVs holds exciting potential for further advancements and their profound impact on underwater exploration:

- Energy Efficiency: Research is ongoing to develop slip rings that minimize energy consumption. Energy-efficient slip rings could extend the operational endurance of ROVs, allowing for longer missions and deeper dives.

- Adaptive Slip Rings: Future slip rings may incorporate adaptive features that adjust their performance based on environmental conditions. For example, slip rings could automatically modulate electrical connections to compensate for variations in water temperature or pressure, ensuring consistent performance.

- Distributed Slip Ring Systems: Distributed slip ring systems, where multiple slip rings work in coordination, are being explored. This innovation could enable redundancy and fault tolerance, ensuring uninterrupted operations even if one slip ring encounters an issue.

- Nanotechnology Applications: Researchers are investigating the integration of nanotechnology in slip rings. This could lead to slip rings with nanoscale coatings that offer unparalleled resistance to corrosion and wear.

- Wireless Data Transfer: Although slip rings primarily transmit electrical signals through physical contact, there is ongoing research into wireless data transfer technologies for specific applications. Wireless data transfer could reduce the need for physical connections, enhancing the maneuverability of ROVs.

These potential advancements not only hold promise for marine ROV systems but also have broader implications for ocean exploration, scientific research, and industrial applications. As slip ring technology continues to evolve, the boundaries of what can be achieved beneath the ocean’s surface will expand, opening up new avenues of discovery and innovation in underwater exploration. In the upcoming sections, we will provide a comprehensive buying guide for selecting the right slip rings for marine ROV systems, empowering operators and enthusiasts to make informed choices for their underwater missions.

Marine ROV System Slip Rings: Buying Guide and Recommendations

Providing a Checklist for Users to Consider When Purchasing Slip Rings for Their ROV Systems

Selecting the right slip rings for your marine ROV system is a critical decision that directly impacts the success of your underwater missions. To assist in making an informed choice, we present a comprehensive checklist of factors to consider:

- Operational Requirements: Begin by defining the specific requirements of your ROV system. Determine the number of slip rings needed, their type (capsule, through-bore, pancake), and the functions they must perform (data transmission, power transfer, etc.).

- Corrosion Resistance: Ensure that the chosen slip rings are engineered for corrosion resistance, as the marine environment is inherently corrosive. Look for materials and coatings that can withstand prolonged exposure to saltwater.

- Durability: Assess the durability of the slip rings. Consider the robustness of their construction and their ability to withstand physical shocks, vibrations, and the rigors of underwater operations.

- Precision: Verify the precision of the slip rings in maintaining signal integrity. High precision is crucial for tasks that rely on accurate data transmission, such as high-definition video feeds or scientific instrumentation.

- IP Ratings: Take note of the IP (Ingress Protection) ratings of the slip rings. Higher IP ratings indicate better protection against dust and moisture ingress, a critical factor for marine ROV systems.

- Material Selection: Understand the materials used in the slip rings’ construction. Stainless steel, bronze, and specialized alloys are common materials that offer corrosion resistance. Select the material that aligns with your specific requirements.

- Payload Capacity: Consider the slip rings’ payload capacity, which determines the maximum weight they can support. Ensure that the chosen slip rings can accommodate the cables and connectors required for your mission.

- Space Constraints: If your ROV has limited space, opt for compact slip rings that fit seamlessly within your system without impeding maneuverability.

- Manufacturer Reputation: Research the reputation of the slip ring manufacturer. Reputable manufacturers often provide high-quality products with reliable performance and customer support.

- Supplier Reliability: Choose a reputable supplier or distributor with a track record of delivering quality slip rings on time. Reliable suppliers can offer guidance and support throughout the purchasing process.

Recommend Reputable Manufacturers and Suppliers

While the market for slip rings is diverse, several manufacturers and suppliers have established themselves as reliable sources of high-quality slip ring technology. Here are a few reputable options to consider:

| No. | Manufacturer | Website |

|---|---|---|

| 1 | Hangzhou Grand Technology | https://www.grandslipring.com/ |

| 2 | Moog Inc. | https://www.moog.com/ |

| 3 | Stemmann-Technik | https://www.stemmann.com/en/home |

| 4 | Schleifring | https://www.schleifring.com/ |

Hangzhou Grand Technology

Hangzhou Grand Technology Co., Ltd. started as a special slip ring manufacturer in 2011. Grown into slip rings, rotary joints, and slip ring assembly experts of today with 6,000 square meter manufacture complex.

Obtained ISO9001, Rosh, CE, and GJB9001B certificates a number of slip rings, rotary joint patents, and proud of our products can meet military grade. Collaborated with universities, institutes, and renowned factories across Asia and Europe including Panasonic, SIEMENS, CSIC, SAMSUNG, HUAWEI, etc.

Moog Inc.

Moog is a leading supplier of high-performance slip rings for various industries, including aerospace. Among their offerings, Moog’s SR Series Slip Rings are designed for the demanding environments of helicopters, excelling in performance, reliability, and customization potential.

Stemmann-Technik

Stemmann-Technik, a part of the Conductix-Wampfler Group, offers a broad range of slip rings, including solutions for helicopters. Their Livietta Slip Ring Assemblies are designed explicitly for harsh and demanding environments in the aviation sector, providing reliable signal and power transmission.

Schleifring

Schleifring is a well-known manufacturer of electromechanical systems, including slip rings customized for various industries. Their Aircraft Slip Rings cater specifically to helicopters, offering robust performance, low wear, and high reliability to meet the challenges of aviation applications.

In summary, the helicopter slip rings market is shaped by multiple players, factors, and technological advancements. Key manufacturers and their products play a critical role in addressing industry demands for high-quality, reliable, and customized slip ring solutions.

If you want to know more about other slip ring manufacturers, you can read Top 10 Slip Ring Manufacturers in China, Top 10 Slip Ring Manufacturers In the USA Market 2023, and Top 10 Slip Ring Industry Key Manufacturers 2023

By considering the checklist and exploring reputable manufacturers and suppliers, you can make informed decisions when purchasing slip rings for your marine ROV system. These considerations and recommendations are essential for ensuring the reliability and success of your underwater missions, enabling you to explore the ocean’s depths with confidence.

Conclusion

In the depths of the world’s oceans, where exploration meets the unknown and challenges abound, marine ROV systems emerge as our windows into the enigmatic underwater realm. These remarkable machines are our eyes, hands, and instruments in a world where humans cannot tread. Yet, behind their intricate systems and multifaceted missions lies a silent hero – the marine ROV system slip ring. In this guide, we have unveiled the hidden yet pivotal role of slip rings and explored their significance in the context of marine exploration. As we conclude our journey, it is crucial to reflect on the importance of slip rings in marine ROV systems and the key takeaways from our exploration.

Slip rings are the unsung heroes of marine ROV systems, serving as the vital bridge between the stationary world above and the dynamic world below the waves. They facilitate seamless electrical connections, enabling the transmission of power, signals, and data essential for the success of underwater missions. Whether inspecting subsea pipelines, conducting scientific research, salvaging valuable assets, or monitoring the health of our oceans, ROVs rely on the reliability and precision of slip rings to fulfill their missions in the challenging marine environment.

Throughout this guide, we have uncovered a wealth of information about marine ROV system slip rings:

- Understanding ROVs: We began by introducing ROVs and their diverse applications in marine industries, emphasizing the critical role of reliable electrical connections in these systems.

- The Role of Slip Rings: We delved into the mechanics and significance of slip rings, exploring how they enable data and power transmission in underwater environments and overcome the unique challenges of maintaining electrical connections in ROVs.

- Key Features to Look for: We discussed essential attributes of slip rings suitable for marine ROV systems, including corrosion resistance, durability, precision, IP ratings, and material selection.

- Types of Slip Rings: We explored various types of slip rings commonly used in marine ROV systems, comparing and contrasting capsule slip rings, through-bore slip rings, and pancake slip rings, and explaining when to use each type based on specific ROV requirements.

- Installation and Maintenance: We offered a step-by-step guide on how to install slip rings in an ROV system and provided maintenance tips to ensure their longevity and performance. We also discussed common issues and troubleshooting methods.

- Case Studies: Real-world case studies highlighted the pivotal role of slip rings in various marine ROV applications, showcasing success stories and challenges overcome with the right slip ring technology.

- Emerging Trends and Future Developments: We explored the latest innovations in slip ring technology for marine ROVs and mentioned potential advancements and their impact on underwater exploration.

- Buying Guide and Recommendations: We provided a checklist for users to consider when purchasing slip rings for their ROV systems and recommended reputable manufacturers and suppliers.

As you embark on your own underwater missions and explore the mysteries of the deep, remember that the reliability and performance of your marine ROV system are intrinsically linked to the slip rings you choose. By making informed decisions and considering the checklist provided in this guide, you can ensure that your ROV’s electrical connections remain robust and dependable, allowing you to unlock the secrets hidden beneath the ocean’s surface. Whether you are a seasoned marine explorer or a newcomer to the world of ROVs, let the knowledge shared in this guide empower you to navigate the depths with confidence, knowing that your slip rings are the steadfast companions of your underwater adventures.

Have questions about our Marine Slip Rings? Fill out the form, and our specialists will get back to you with detailed answers.