This article explores the importance, functionality, and different aspects of automotive slip rings and addresses users’ common concerns. Gain insights into technological advancements, future predictions, and tips for buying and maintaining automotive slip rings.

Introduction to Automotive Slip Rings

As vehicles incorporate more advanced features and complex systems, the significance of efficient power and signal transmission between components has grown. In this article, we take an in-depth look into automotive slip rings, essential devices that ensure smooth electrical communication between stationary and rotating parts in vehicles.

This comprehensive guide delves into the importance of automotive slip rings in the auto industry, their various applications, advantages, and potential drawbacks, as well as tips for buying and maintaining them. The article also discusses recent technological advancements, and the future of automotive slip rings, and addresses common issues faced by users.

Within the context of an increasingly connected and technologically driven automotive landscape, automotive slip rings play a vital role in modern vehicles, ensuring reliable functionality of electrical and electronic components. This, in turn, enhances the driving experience and elevates the overall performance of advanced automotive systems.

Understanding Automotive Slip Rings

In an era where technology underpins the operation of most, if not all, vehicle systems, understanding the devices that facilitate this seamless operation has become imperative. Automotive slip rings fall into this category of vital components that often go unnoticed.

An automotive slip ring, in its simplest terms, is an electromechanical device designed to transmit electrical power and signals from a stationary to a rotating structure within a vehicle. The need for this transmission arises from systems where turntable operations occur, such as steering controls or alternator systems, which are physically separated but require a consistent electrical connection to function effectively.

Functionally, an automotive slip ring mechanizes a connection via conductive tracks and brushes. As the rotating part moves, the stationary brushes maintain contact with the conductive tracks, allowing continuous electrical communication between the stationary and moving sections. This ensures the uninterrupted operation of various systems dependent on this electrical transmission.

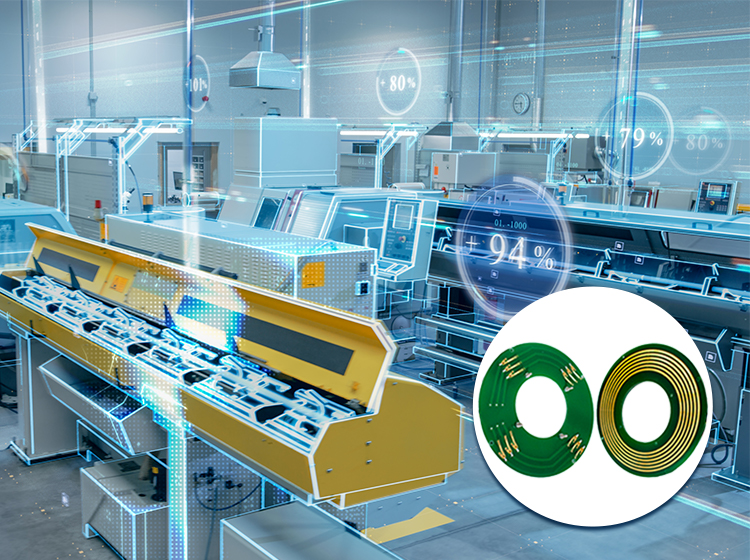

Diverse vehicle systems accommodate slip rings of varying kinds. The type of automotive slip ring employed largely depends on its intended application. Broadly, these can be classified into three types – Pancake slip rings, which are flat and circular; Capsule slip rings, small-size slip rings used for signals and data transfer; and Through Bore slip rings, which allow additional mechanical or fluid rotary joints to pass through the center. Each type of slip ring caters to different functional requirements based on vehicle design and specific applications.

In a world where vehicles are evolving into complex machines with interconnected systems, understanding the role and function of components like automotive slip rings further enhances our grasp of modern vehicle dynamics.

The Automotive Slip Ring: A Deep Dive

As components of vehicles become more sophisticated, the interplay between fixed and moving parts takes on an additional layer of complexity. This is where an automotive slip ring, a vital but often underappreciated player in the automotive industry, steps in.

An automotive slip ring is an ingenious device delivering an array of solutions for transmitting power and signals between stationary and rotating parts. Imagine a scenario where a cable is connected to a rotating mechanism without a slip ring; the cable would inevitably twist upon rotation, affecting the function and efficiency of the system. This is where automotive slip rings literally ‘step up and turn’, acting as an interface to bridge this rotating gap, ensuring cables and wires are free from twists and spins. They maintain constant, uninterrupted connections that enable power or data to be transferred seamlessly, regardless of the position of the rotating component.

One of the most critical aspects of automotive slip rings is their versatility and adaptability, filling in essential roles across a variety of vehicle systems. For instance, one of their common deployments is within the steering wheel assembly. Here, they support an array of controls, including the horn, audio systems, airbags, and other steering wheel-mounted controls, all while allowing the steering wheel unrestricted, circular motion.

They also serve a key role in electric vehicles, ensuring the steady operation of the powertrain control module (PCM), and facilitating the smooth operation of the vehicle’s high-speed rotating systems. Other traditional roles include their use in alternators, wind turbine generators, cable reels, and test equipment.

Imagining a modern vehicle without slip rings is tantamount to visualizing a computer without a processor. They serve a multitude of functions, each equally integral to vehicle operation and performance. As we continue to update and innovate automotive technology, the vital role that automotive slip rings fill can only grow more pronounced.

Application and Uses of Automotive Slip Rings

In the world of automobiles, where designs and technologies are continually evolving, the importance and application of automotive slip rings have witnessed a remarkable scale-up. They cater to an array of applications where durable and reliable transmission of electrical power and signals from a stationary platform to a rotating part is required. As such, they hold a key role in different vehicle systems, ensuring smooth operational flows and contributing to the automobile’s overall performance.

One of the primary applications of automotive slip rings is within the steering wheel assembly. Here, they enable the connection of crucial electronic systems such as airbag systems, horns, audio controls, and cruise control settings. The automotive slip ring ensures that even as the steering wheel rotates, there’s an uninterrupted flow of power and data to these components. It adapts to the steering wheel’s rotational movement to keep these systems working flawlessly, enhancing the safety and convenience of the driving experience.

In the domain of alternate power generation within vehicles, automotive slip rings are vital components of alternators. They help maintain an efficient transmission of the power generated by the engine to charge the vehicle’s battery and power the electrical systems.

Moreover, as the world is swiftly moving toward electric vehicles, the role of automotive slip rings in this sector cannot be understated. They are crucial to the functionality of electric vehicle charging stations, where their key role is to ensure an efficient transfer of power during the charging process. Furthermore, they support the management of powertrains in electric vehicles, facilitating the vehicle’s continual access to power while on the move.

This broad range of applications and use cases of automotive slip rings within various vehicle systems underscores their versatile functionality in the real world. Their ability not just to fit into but also enhance the efficient operation of diverse vehicle systems truly highlights their importance in the automotive industry.

Advantages and Disadvantages of Automotive Slip Rings

Automotive slip rings, like any other intricate automotive component, come with their share of advantages and disadvantages. They have a significant role to play in ensuring the smooth operation of vehicle systems, yet they present certain challenges that users need to be mindful of in the pursuit of vehicle efficiency and longevity.

Among the benefits, the key advantage of automotive slip rings is the enhancement in performance and management they bring to various vehicle systems. By enabling seamless transmission of electricity between stationary and rotating components, they help facilitate the efficient operation of systems like alternate power generation, steering controls, and electric vehicle power management.

In addition, they help minimize wear and tear on vehicle systems. By ensuring that cables and wires do not twist or fray due to continuous rotation, slip rings contribute to the increased durability of these components, saving costs on frequent repairs or replacements.

Moreover, automotive slip rings are engineered to be reliable and durable. Thanks to their rugged design, they can withstand harsh environments and conditions that are commonly encountered in automotive operations, further adding to their longevity.

However, despite these advantages, automotive slip rings are not without their limitations. One of the primary concerns is regular maintenance and cleaning requirements. Being electromechanical devices, these slip rings are subject to wear and tear and demand regular cleaning to prevent dust and grime build-up, which can cause inefficient operations.

Another issue is electrical noise and contact resistance, which may compromise the accuracy and integrity of the signal being transferred. Adverse effects of these can lead to malfunctioning systems and compromised vehicle performance.

Lastly, the cost of automotive slip rings can vary significantly. Depending on the quality, make, and specific application, acquiring and maintaining them could be an expensive affair.

Understanding the advantages and limitations of automotive slip rings is vital to maximizing their benefits and mitigating potential issues. By keeping these factors in mind, one can make an informed decision when buying and maintaining them, resulting in a better operational lifetime for the vehicle’s systems.

Technological Developments and Innovations in Automotive Slip Rings

Automotive slip rings, much like other automobile components, have been subject to continual innovation and advancements to meet the ever-evolving automotive industry’s needs. These developments have contributed to more efficient, reliable, and high-performing automotive slip rings, thereby expanding their use and improving overall vehicle performance.

Recent advancements have seen the emergence of automotive slip rings with improved design characteristics. For instance, the development of slip rings with contact technology that minimizes friction and wear contributes to their longevity and reduces the need for frequent maintenance. Additionally, high-end materials like precious metal brushes and rings have been introduced in the design to minimize electrical noise and enhance signal integrity.

Furthermore, the concept of modular slip rings has been introduced, which allows for easy customization depending on the specific application. This customizability makes them adaptable to different vehicle systems, eliminating the need for several unique slip rings, and therefore reducing costs.

From the functionality perspective, consistent improvements in technology have led to slip rings that provide even more reliable and efficient transmission of power and signals between the moving and stationary components of the vehicle. Signal stability and bandwidth capabilities have seen significant enhancements, ensuring smoother data and power transmission.

Another notable innovation is the development of slip rings capable of handling higher currents and power loads, which directly cater to the increasing power requirements of advanced electric and hybrid vehicles. This progression has ensured that slip rings stay relevant and efficient in the rapidly evolving electric vehicle segment.

Resilience in design has also been prioritized, with advancements leading to the development of slip rings that can withstand harsher environmental conditions. This makes slip rings more reliable and durable for use across various terrain and weather conditions, increasing their lifespan and thereby reducing overall maintenance costs.

These continual technological advancements and innovations in design and functionality exemplify the commitment to enhancing the automotive industry’s performance and output. As we move further into a technologically driven era, the bar for these solutions, including automotive slip rings, will only be raised higher.

Users’ Concerns about Automotive Slip Rings

While automotive slip rings play a prominent role in the smooth functioning of various vehicle systems, users may face challenges related to system performance, maintenance, repair, and associated costs. Understanding these concerns can help one make informed decisions about their investment in automotive slip rings and ensure the best possible outcomes.

Common Issues Faced by Users

Users might encounter issues related to poor performance of the slip rings if they become contaminated over time. The build-up of dust, debris, or grime could lead to increased friction and contact resistance, affecting the quality of the electrical signal and power transmission. Minor malfunctions caused by such factors could reflect poorly on the overall vehicle performance and efficiency.

Another concern is the potential premature wear and tear of low-quality slip rings. Users may experience shorter lifespans of such components, directly affecting the performance of the systems they support and necessitating frequent replacements.

Maintenance and Repair Requirements

Regular maintenance, including cleaning and timely replacement of worn-out parts, is necessary to keep automotive slip rings in optimal working condition. However, meeting these requirements can be time-consuming, and users may not be well-versed with the nuances of proper maintenance. Furthermore, wear and tear over time might necessitate repairs or replacement of certain components, which may be an added inconvenience if such issues aren’t addressed promptly.

Costs Associated with Automotive Slip Rings

Automotive slip rings can vary significantly in terms of costs, depending on factors such as quality, make, and specific applications. Users should be ready to account for initial purchase costs, as well as ongoing maintenance and potential repair or replacement costs.

Initial costs can be high, particularly for slip rings made with advanced materials such as precious metals or customized, high-performance designs. The necessary routine maintenance and component replacements, which ensure optimum functioning, can also add further expenses to the overall investment.

In conclusion, addressing the concerns related to automotive slip rings involves understanding the user’s specific needs and budget constraints. Making informed decisions about the selection, maintenance, and repair of these crucial components can significantly impact associated costs and the overall performance of the vehicle systems they support. Investing prudently in high-quality products and proper upkeep can lead to better outcomes and increased satisfaction for users.

Tips for Buying and Maintaining Automotive Slip Rings

Given the vital role of automotive slip rings in the efficient functioning of vehicle systems, making informed purchase decisions and committing to regular maintenance can significantly impact their performance and longevity. Below are some guidelines to assist in the process of buying and maintaining these crucial components.

Guide to Choosing High-Quality Automotive Slip Rings

When choosing automotive slip rings, consider their intended application. Different systems may require different designs or specifications, so it’s essential to confirm compatibility with the vehicle’s requirements.

Quality is a critical factor when investing in automotive slip rings. Materials used in the slip ring construction should be durable and reliable to ensure optimal performance. Rings made from high-end materials like precious metals may have better electrical properties and longer operational life.

It’s important to consider the reputation of the manufacturer. Those with a solid track record for producing reliable and high-performing automotive slip rings are more likely to provide a product that meets or exceeds expectations. Furthermore, warranty policies can offer some level of protection for your investment.

Recommendations for Maintaining Automotive Slip Rings

Regular maintenance of automotive slip rings is essential to preserving their efficiency and extending their lifespan. This typically involves periodic cleaning to remove any built-up dust, grime, or debris that could cause unnecessary friction and wear.

It’s also necessary to inspect slip rings regularly for signs of wear or damage. Any components showing early indications of wear and tear should be promptly replaced to prevent more substantial issues or system malfunctions.

Using compatible and high-grade contact materials can also prolong the life of automotive slip rings. These materials can enhance electrical properties and reduce wear, leading to more effective power and signal transmission.

Lastly, it is highly recommended to consult the manufacturer’s guidelines for maintenance and part replacement schedule. These instructions are designed for the specific product and will likely lead to a longer operational life and optimal function.

To conclude, purchasing high-quality automotive slip rings and committing to their regular maintenance can ensure their efficient functioning. It will indeed be a valuable investment that pays off in long-term vehicle performance and safety.

The Future of Automotive Slip Rings

Automotive slip rings have become increasingly indispensable components in the automobile industry with advancements in technology. However, as the industry continues to evolve with its rapid adoption of new-age innovations like autonomous vehicles, electric vehicles, and various communication systems, the future of automotive slip rings promises to be even more eventful and significant.

One of the key advancements likely to shape the future of automotive slip rings lies in the growth of electric and hybrid vehicles. These rapidly advancing sectors pose specific challenges like higher current and power loads due to their advanced power systems. To cater to these needs, automotive slip rings are expected to continue evolving toward handling higher capacities. The development of slip rings that can withstand these increased power loads will be essential to maintaining the efficiency of these modern vehicles.

Alongside, the push towards autonomous and connected vehicles calls for efficient and highly reliable data transfer systems. This implies that future slip rings might warrant even greater emphasis on signal integrity and minimizing electrical noise, as high-speed data transmission would be key to achieving the operational efficiency of these vehicles.

Moreover, the push for highly customizable and modular slip rings is likely to continue, which will allow for greater flexibility and adaptability to different vehicle systems and needs. This approach could help in cost reduction and ease of installation, making the automotive slip rings even more user-friendly.

Further down the line, with advancements in material science and engineering, we might see materials with superior electrical properties and wear resistance being used in the construction of slip rings. This could drastically enhance their performance, significantly reduce wear and tear, and ultimately lead to greater durability.

The future of automotive slip rings is paved with potential advancements in design, functionality, material science, and even the very concept of what a slip ring can achieve. With their pivotal role in modern and futuristic vehicles becoming more entrenched, these advancements come as promising news for more efficient, reliable, and user-friendly automotive systems.

Conclusion

Automotive slip rings are essential components in modern vehicles, ensuring efficient power and signal transmission between stationary and rotating parts. As automotive technology advances, the role of slip rings will continue to evolve, making it crucial for users to understand their importance, address common concerns, and maintain optimal functionality.

See What We Can Do