In this article, we will delve into the intricacies of electric slip rings—devices that play a crucial yet often overlooked role in myriad electrical applications. From understanding their fundamentals to exploring future trends, this article provides a comprehensive guide on electric slip rings.

Introduction to Electric Slip Rings

An electric slip ring can be loosely likened to a bridge – it forms a critical link between static and rotating parts of an electromechanical system. Think of a playground merry-go-round: if you had to pass a glass of water to someone on the other side, it would be challenging without spilling water. However, if you were both on the routine together, despite the spinning motion, passing water is easy. Electric slip rings perform a similar role in electrical engineering, where they prevent ‘spilling’ or loss of electrical signals.

The primary function of an electric slip ring is to facilitate the transmission of power and electrical signals from a stationary part to a rotating component of an electromechanical system. This functionality is crucial because rotating parts cannot connect to power sources or transmit data using stationary wires as they would tangle or snag.

Essentially, electric slip rings allow us to overcome a major roadblock in systems involving rotation. By doing so, they have paved the way for innovative devices, machines, and technologies, thus anchoring their importance in the heart of modern engineering.

Understanding Electric Slip Rings

Electric slip rings are deceptively simple in their operation but incredibly ingenious in the problem they solve. At the core of their functionality is the principle of maintaining an electrical connection between a stationary system and a rotating one, a task that seems straightforward until one considers the complexities of continuous rotation and the need for uninterrupted power and data transmission.

How Electric Slip Rings Work

Imagine a wind turbine, its blades turning tirelessly against the sky. Inside, electrical components need to communicate with static infrastructure—enter the slip ring. A typical electric slip ring consists of a metal ring that rotates along with the turbine blades (or any rotating part of a machine). Against this ring, at least one stationary brush presses gently, creating a continuous electrical circuit as the ring spins. This brush is connected to the stationary structure and channels electrical signals and power through the rotating ring, allowing for seamless operation of the rotating parts without the risk of wire tangling or snapping.

Key Components of Electric Slip Rings

To appreciate the complexity and ingenuity of slip rings, it helps to understand their key components:

- The Rotor: This is the part of the slip ring assembly that rotates. It is typically a metal cylinder or ring that’s attached to the rotating part of the machine. The exterior surface of the rotor is conductive, usually made of metal, facilitating the transfer of electrical signals and power.

- The Brush: The brush, or several brushes, remain stationary and are in constant contact with the rotating ring. Made from materials that conduct electricity, these brushes pick up or transfer electrical signals and power from the stationary part of the assembly to the rotor, ensuring uninterrupted transmission as the rotor spins.

- Housing: The structure encasing the rotor and brushes protects them from environmental factors, such as dust, moisture, and potential mechanical wear and tear. It also secures the components in place, ensuring that the brushes maintain proper contact with the rotor.

Types of Electric Slip Rings

Given the diverse needs of industries that utilize rotating machinery, several types of electric slip rings have been developed, each tailored for specific applications:

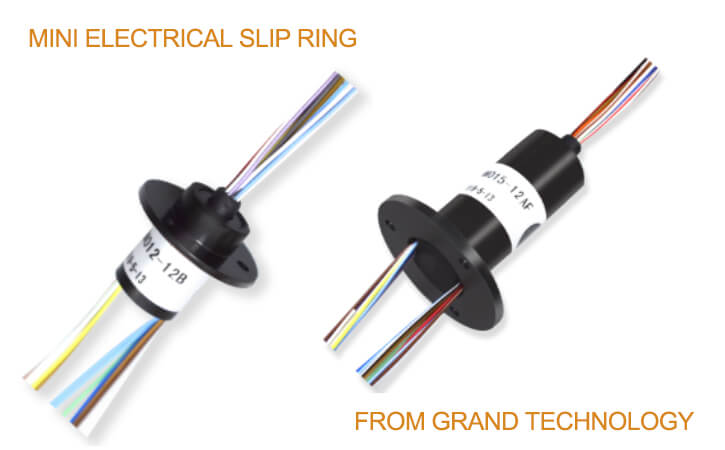

Capsule Slip Rings

Compact and designed for small-scale applications, capsule slip rings are often found in CCTV cameras and robotics. Their small footprint makes them ideal for limited spaces, offering reliable power and signal transmission in a diminutive package.

Through-Bore Slip Rings

These slip rings feature a hollow center, allowing them to be mounted over a cylindrical shaft. This design is common in machinery requiring central mounting, such as medical equipment and wind turbines, providing a neat solution for complex assemblies.

Pancake Slip Rings

Characterized by their flat, disc-like shape, pancake slip rings are suited for applications where height is constrained. Though they offer a larger diameter, their design minimizes vertical space usage. They’re commonly used in equipment where space is at a premium but a large contact area is needed for high power or signal transmission requirements.

Each type presents a unique set of characteristics, tailored to meet the diverse requirements of various applications, showcasing the adaptability and essential nature of slip rings in modern electromechanical systems. Whether transmitting power to a rotating camera or ensuring the operation of a grand wind turbine, electric slip rings are the unsung heroes in the background, ensuring efficiency and innovation in countless applications across the globe.

Applications of Electric Slip Rings

Electric slip rings have become an indispensable component across various sectors where rotational motion and electrical signaling or power transfer intersect. Their flexibility and adaptability to different engineering requirements make them a universal solution to a common mechanical constraint—how to maintain an electrical connection with rotating components without hindering their movement.

Diverse Industries Harnessing Electric Slip Rings

- Renewable Energy: In the realm of renewable energy, particularly wind turbines, slip rings play a vital role. They enable the transfer of control signals and power to the yaw and pitch mechanisms, which are essential for optimizing the position of the blades and the orientation of the turbine according to wind conditions.

- Industrial Machinery: Many automated manufacturing processes utilize rotary tables, which require slip rings. They enable these tables to rotate smoothly while controlling robotic arms or tools, thus streamlining production processes where precision and reliability are paramount.

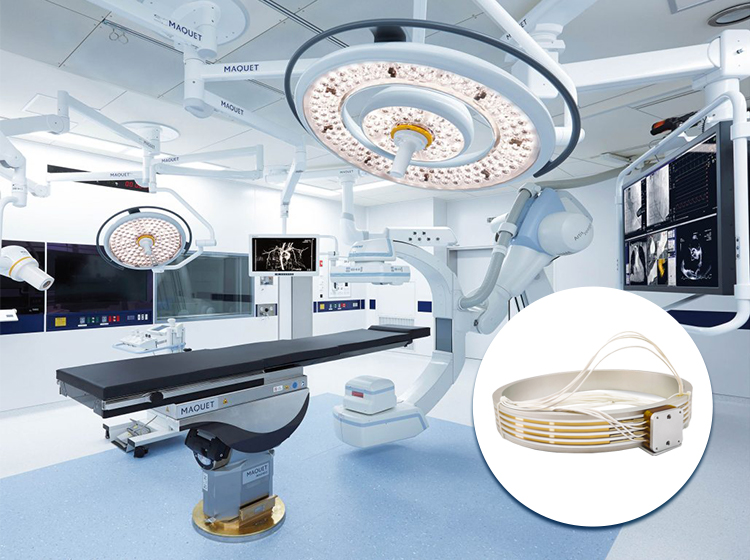

- Medical Equipment: The healthcare sector benefits immensely from slip capabilities in advanced diagnostic imaging machines, such as CT scanners. Slip rings in these machines allow the gantry to rotate around the patient, capturing numerous images from different angles which are crucial for creating detailed cross-sectional views of the body.

- Surveillance Systems: Similarly, in the security industry, CCTV cameras often incorporate electric slip rings. These allow for uninterrupted 360-degree rotation, providing a comprehensive field of surveillance without the need to constantly reset the camera’s position.

The Role of Electric Slip Rings in Specific Applications

Each application capitalizes on the basic principle of an electric slip ring but adapts it to meet unique requirements:

- In wind turbines, the slip ring may carry high currents for power and delicate signals for control systems simultaneously, designed to withstand the harsh environmental conditions found at great heights.

- Regarding rotary tables, slip rings often integrate into the tabletop’s center, providing a clean and controlled electrical interface that can handle the complex, multi-channel signaling required for automation.

- In medical equipment, particularly imaging systems like CT scanners or MRI machines, slip ring technology ensures the transmission of data and power to the rotating parts of the scanner, supporting the machine’s demanding performance criteria and patient safety requirements.

- For CCTV cameras, slip rings must be compact and highly reliable, ensuring smooth operation over extended periods, as security cameras are operational round the clock and often exposed to various environmental conditions.

Each application highlights a specific facet of an electric slip ring’s utility: the ability to support complex electrical systems in motion, fulfill exacting industry standards, and adapt to the operational demands of high-stakes environments. This diversity speaks to the inherent versatility of slip rings, reflecting their integral role in the smooth operation of equipment across multiple sectors.

Electric Slip Ring User Concerns and Considerations

Electric slip rings serve as a pivotal component in a multitude of applications. Users considering slip rings must weigh several factors to ensure that the solutions they adopt not only fulfill technical requirements but also offer reliability and value over time.

Durability and Maintenance

The durability of a slip ring is a significant factor influencing user preference. In sectors like renewable energy or medical facilities, where equipment operates near-constantly and downtime can have severe implications, a slip ring with a longer lifespan is highly valued. Users generally favor designs that offer robust construction and materials that can endure the stress of constant rotation and environmental exposure.

The maintenance requirements of slip rings further influence their practicality in various settings. High-maintenance slip rings may lead to increased operational costs and downtime. In contrast, slip rings that are designed to be low-maintenance, with accessible components and straightforward procedures for routine checks and cleaning, are often preferred. This ensures that systems remain operational with minimal interruption, which is vital for applications like surgical equipment or communication satellites.

Signal and Power Transmission Efficiency

The efficiency with which a slip ring transmits signals and power is paramount. The integrity of this transmission is crucial in applications where data and power loss can result in significant consequences, such as in critical industrial automation processes or safety monitoring systems. Users require slip ring solutions that guarantee minimal electrical noise and resistance to ensure the fidelity of signal and power transfer, particularly in sensitive instrumentation.

Customization and Compatibility

Given the diverse range of applications for electric slip rings, the availability of custom solutions is often a consideration. Tailored designs can cater to unique operational parameters, including size constraints, number of circuits, and type of signal or power to be transmitted. Customization ensures that slip rings fully integrate with existing systems and meet specific technical requirements, which is critical for seamless operation.

Compatibility with existing systems and equipment is another concern. Users need to evaluate whether a new slip ring can be easily integrated into their current setup without necessitating extensive modifications or upgrades to other components, which can increase costs and complexity.

Cost

The initial investment in a slip ring system is often weighed against its long-term benefits. High-quality slip rings with superior performance and lower maintenance demand may come with a higher upfront cost but can result in significant savings over time due to reduced downtime and repair expenses.

Users also consider cost comparisons with alternative rotary electrical interface solutions. While slip rings are the go-to choice for 360-degree continuous rotation, alternative options like rotary transformers or wireless power transfer systems might be viable in certain scenarios, although they come with their limitations and may not be suitable for transmitting data.

In sum, electric slip rings must be measured against an array of user considerations, balancing cost against efficiency, durability, customization, and compatibility, to ensure the most effective and reliable solution is employed for each unique demand.

Electric Slip Ring Technical Challenges and Solutions

Despite their fundamental efficacy, electric slip rings are not without their challenges. The need to work in diverse operating conditions, across varying industries, presents technical impediments that must be addressed for optimal performance. However, advancements in technology and design innovations are offering vital solutions to these problems.

Common Technical Challenges

- Wear and Tear: Perhaps the most common challenge is the wear and tear arising from the constant physical contact between the brushes and the rotating ring. Prolonged usage can lead to degradation of these components, resulting in unreliable power and signal transmission, or potential failure.

- Electrical Noise: Noise in electrical systems, otherwise known as interference, is a frequent issue with slip rings. This is particularly problematic in applications where precision and reliability of signal transmission are critical, such as in automated industrial machinery or medical diagnostic equipment.

- Environmental Factors: Electric slip rings often find use in environments that expose them to harsh conditions. These include extreme temperatures, dust, moisture, or corrosive substances, each posing its own set of challenges, affecting the slip ring’s longevity and operational reliability.

Emerging Technologies and Improvements

Despite these challenges, ongoing technological advances and design improvements are bolstering the performance and resilience of electric slip rings.

- Improved Materials and Design: Newer slip rings utilize high-performance materials and innovative design approaches to reduce wear and tear. For instance, brushes made from advanced composite materials can offer more extended service life and increased resistance to frictional damage. Similarly, optimized ring geometries can distribute wear evenly, boosting the durability of the system.

- Noise Reduction Technology: Efforts to reduce electrical noise have led to the improvement of shielding methods, grounding techniques, and the use of low-noise materials inside the slip ring. Signal conditioning methods are also being employed to improve signal strength and integrity, helping to alleviate issues arising from electrical noise.

- Environmental Sealing and Material Choice: Though slip rings are always subject to environmental challenges, recent developments in design have improved their resilience. These include better sealing methods to protect against dust and moisture ingress, the use of corrosion-resistant materials for components, and designs capable of withstanding thermal stress, enabling stable operation even under hostile conditions.

Tech-driven advancements paint a promising panorama for the future of electric slip rings, as these bring robust solutions to longstanding issues. By marrying innovation and reliability, the challenges arising in the operational lifetime of these rings are continually addressed, reinforcing their importance in the smooth functioning of electromechanical systems across a myriad of applications.

Electric Slip Ring Future Trends in Slip Ring Technology

Electric slip rings have been integral to many industries for quite some time. However, as technological advancements continue to revolutionize various sectors, we are bound to see significant innovations and new trends in slip ring technologies. These developments will be influenced by the evolving demands in industries such as renewable energy and robotics.

Innovations on The Horizon for Slip Ring Technologies

- Smart Slip Rings: As the world moves towards Industry 4.0 and Internet of Things (IoT) applications, smart slip rings are poised to be the trend of the future. These slip rings could incorporate sensors for real-time monitoring of their performance parameters, such as wear level, temperature, and electrical noise. This data could be transmitted for remote monitoring and predictive maintenance, thus boosting the overall longevity and reliability of the system.

- Wireless Energy Transfer: There is an escalating interest in wireless energy transfer technology to replace traditional slip ring applications in certain scenarios. This technology can transmit power without physical contact, thereby reducing wear and tear. Coupled with data transmission technologies such as Bluetooth or Wi-Fi, this could offer a holistic solution for rotary interfaces in specific applications.

- High-Speed Slip Rings: As communication and data processing speeds increase, there will be a demand for high-speed slip rings that can keep pace. These would need to transmit high-frequency signals without significant loss or degradation, which is an exciting frontier for slip ring technology.

Evolving Demands Shaping The Development of New Slip Ring Designs

- Renewable Energy: As industries progressively switch to renewable energy resources, wind turbines are becoming ubiquitous. This shift requires reliable and durable slip rings that can withstand harsh weather conditions while maintaining efficient electricity transmission. The increasing size and power output of wind turbines may drive the development of larger, more robust slip rings capable of handling higher currents and voltages.

- Robotics: As automation takes center stage across several industries, the demand for slip rings in robotic arms systems is due to growing. These slip rings will need to offer high precision and reliability in power and signal transmission across multiple channels. Next-generation robotics could see the development of miniaturized, low-friction slip rings with integrated data and power transmission.

In conclusion, these evolving trends and innovations speak volumes about the direction in which slip ring technology is headed. Driven by the increased demand from various sectors toward more robust, reliable, and smart systems, the future of slip rings appears both promising and exciting.

Conclusion

Electric slip rings, though simple in concept, play an important role in modern electrical applications. As their technology evolves, so too will their impact across industries and applications.

FAQs About Electric Slip Ring

Q: What is the primary function of an electric slip ring?

A: An electric slip ring’s primary function is to transmit power and electrical signals from a stationary to a rotating structure.

Q: What are some common types of electric slip rings?

A: Some common types include capsule slip rings, through-bore slip rings, and pancake slip rings.

Q: What challenges are associated with electric slip rings?

A: Wear and tear and electrical noise are common challenges, though advancements in technology are beginning to address these issues.

Q: What is an electric slip ring and how does it work?

A: An electric slip ring is a mechanical device that allows the transmission of power and electrical signals from a stationary structure to a rotating one. It works by having rings that are connected to the power source and brushes that remain in contact with these rings to conduct electricity as they rotate. This allows for continuous power and signal transmission without the need for an interruption.

Q: How long do electric slip rings typically last?

A: The lifespan of an electric slip ring largely depends on its usage, environmental conditions, and maintenance routine. Typically, slip rings can last anywhere from a few years to over a decade. The use of high-quality materials and adherence to regular maintenance schedules can significantly increase their operational life.

Q: Can slip rings transmit data as well as power?

A: Yes, slip rings are capable of transmitting both data and power simultaneously. They are designed to accommodate various types of data protocols and electrical currents, making them versatile for a multitude of applications, including those requiring the transfer of control signals, video signals, and other data forms.

Q: Are there any slip rings that can operate in extreme environments?

A: Yes, certain slip rings are explicitly engineered to withstand extreme conditions, such as high or low temperatures, high levels of humidity, and exposure to corrosive substances. These usually feature specialized materials and sealants that protect against environmental factors.

Q: What maintenance does an electric slip ring require?

A: Maintenance for electric slip rings typically includes periodic cleaning, ensuring that the contacts are free of debris, and verifying the integrity of the electrical connections. Regular inspections can help identify wear and tear on the brushes and rings early, allowing for timely replacements to avoid system failures.

Q: How do I choose the right slip ring for my application?

A: When choosing a slip ring, consider the operating environment, rotational speed, type of data, power to be transmitted, the number of circuits required, and the physical size constraints. For complex systems, it’s often best to consult with a slip ring manufacturer to design a custom solution that fits the specific needs of your application.

Q: Can slip rings be customized for specific applications?

A: Absolutely. Many manufacturers offer custom slip ring solutions that are tailor-made to meet the unique requirements of specific applications. This can range from altering the size and configuration to adjusting the materials used to suit particular environmental or operational conditions.

Q: What impact does electrical noise have on slip ring performance?

A: Electrical noise can disrupt the transmission of data and degrade the quality of power transferred through a slip ring. Slip rings must have proper shielding, grounding, and noise suppression techniques in place to minimize such interferences, especially in sensitive applications.

See What We Can Do