A slip ring housing is an essential mechanical and electrical component often defined as a protective case that shields the crucial parts of the slip ring assembly. The housing provides a level of security for the device’s inner components, such as the brushes and the rotating assembly that creates the electrical connection. It not only offers physical protection but also enhances the performance of the slip ring by insulating it from environmental factors and potential electrical interferences.

The importance of slip ring housing spans across myriad industries. These include, but are not limited to, wind energy, robotics, medical technology, military equipment, and marine applications. The selection, design, and type of housing have significant implications for the durability, maintenance, and overall performance of the slip ring in the specific application. It ensures the uninterrupted and efficient transmission of electricity, signals, and data, which are critical for the optimal performance of many industrial machines and equipment. This makes the slip ring housing an indispensable component that is often carefully chosen after evaluating various factors such as quality, cost, environmental conditions, and technical requirements.

Types of Slip Ring Housing

When it comes to classifying slip ring housings, two broad categories are considered – those based on the materials used and those based on specific application requirements.

Material-based classifications:

Materials used in the construction of slip ring housings have a significant influence on aspects such as longevity, resistance to various environmental conditions, maintenance requirements, and cost. The most common materials include:

- Plastic Slip Ring Housing: Best suited for lightweight and cost-effective applications, plastic housings are resistant to corrosion but may not withstand high temperatures or extreme mechanical stress. They are usually used in compact and lower-speed slip rings where electrical interference is not a pressing concern.

- Aluminum Slip Ring Housing: Aluminum slip ring housings provide an excellent balance between weight, mechanical strength, and cost. They have superior heat dissipation properties which can be crucial in high-speed or high-power applications.

- Stainless Steel Slip Ring Housing: These housings offer the highest level of durability and resistance to mechanical stress, high temperatures, and corrosive environments. Stainless steel housings are used in high-end applications where durability, reliability, and performance are imperative.

Application-based classifications:

The design and features of slip ring housing often vary significantly depending on the particular use-case requirements:

- Compact Slip Ring Housing: These housings are used in compact slip rings that are designed to fit into small spaces typically found in camera systems, medical equipment, and miniature robots.

- Modular or Sectional Slip Ring Housing: Such housings offer versatility in design and allow for easy customization and scalability. They are used in applications with varying or future-expandable power and data transmission requirements.

- High-Speed Slip Ring Housing: Designed to withstand high rotational speeds with efficient heat dissipation, these housings are common in applications like turbines, rotary tables, and other high-speed machinery.

- High-Temperature Slip Ring Housing: These housings are built to resist the damage caused by elevated temperatures, making them suitable for applications such as induction heating systems, ovens, and applications within the metallurgical industry.

- Waterproof Slip Ring Housing: Waterproof housings are typically used in marine, underwater, or outdoor applications. These housings are designed to prevent ingress of water and moisture, ensuring the reliability and longevity of the enclosed slip ring.

Key Components of Slip Ring Housing

A slip ring housing is critically composed of several interconnected components. Understanding these components is key to an in-depth comprehension of how slip ring housings work and how to select the ideal one for specific applications.

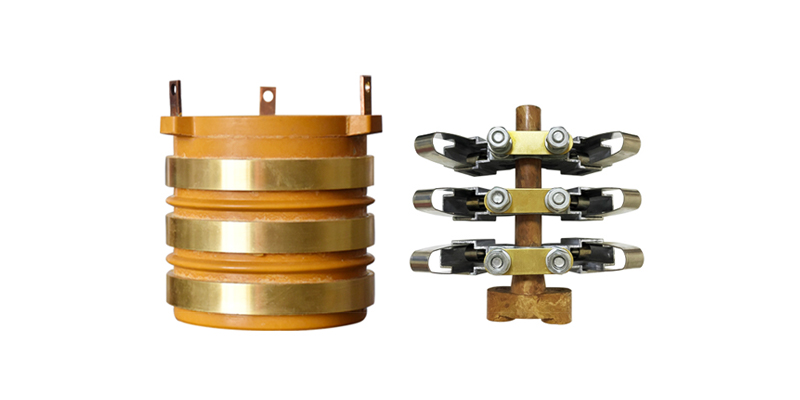

Slip Ring Assembly:

The slip ring assembly is the heart of the slip ring housing, providing the fundamental function of enabling the transmission of electrical energy or signals from a stationary source to a rotating part. At its most simplified, it consists of a ring typically made of a conductive material that rotates with the device and some stationary contact points (or “brushes”) to transfer the electrical current.

Bearings:

Bearings play a vital role in the functionality of slip ring housings. They provide the mechanical support required for the rotation of the slip ring in the housing. Moreover, they are the crucial elements that ensure a smooth, efficient rotation with minimal friction. The performance and lifetime of the bearings significantly influence the overall performance and lifetime of the slip ring assembly and hence the selection of high-quality bearings is critical.

Brush System:

The brush system, consisting commonly of graphite or metal brushes, is responsible for maintaining constant electrical contact with the moving ring. This ensures consistent and effective transmission of the electrical or signal currents. The dimension, material, and configuration of the brush system strongly influence the quality of contact, rate of wear and tear, electrical noise, and other performance parameters of the slip ring.

Housing Material:

Finally, the material from which the slip ring housing is constructed demands attention. As mentioned earlier, the housing can be made from a variety of materials such as plastic, aluminum, or stainless steel. The chosen material influences several aspects, including durability, resistance to environmental factors, maintenance requirements, and in certain scenarios, performance characteristics. The selection of the housing material largely depends on the specific requirements of the application.

Factors to Consider When Choosing Slip Ring Housing

When selecting a suitable slip ring housing, multiple intertwined factors need to be considered to ensure optimal performance, maintenance, safety, and longevity. Each factor will vary depending on the unique context, application, and requirements.

Operating Environment:

The environment in which the slip ring assembly will operate is a significant determinant in choosing the housing. Elements such as temperature, humidity, exposure to dust, corrosive substances, shock, and vibration all crucially impact the housing choice. Diverse environments call for different housing materials and designs to protect the assembly and ensure efficient operation over time.

Rotation speed is a critical factor that affects the wearing of the contact points and heat dissipation. Higher rotation speeds could lead to a higher degree of wear and tear and increased heat generation. Therefore, when dealing with high-speed applications, you should choose a slip ring housing designed to withstand these conditions, maybe with superior materials, bearing designs, and heat dissipation properties.

Required Electrical Performance:

The electrical performance requirements, such as current and voltage ratings, signal integrity, and insulation resistance, significantly influence the choice of slip ring housing. For high-power applications or systems requiring high-quality signal transmission, you’ll need a slip ring housing designed to meet these needs, possibly including better insulating materials and a more advanced brush system.

Housing Material Durability:

The durability of the housing material is crucial for the overall lifespan and reliability of the slip ring assembly. This ties back to the operative environment – abrasive conditions, for example, would require a housing made of more durable material such as stainless steel, while a less stressful environment could afford something less rigid, like plastic.

Maintenance Requirements:

The ease and frequency of maintenance can influence the choice of slip ring housing. In some industrial environments that prioritize minimal downtime, housings designed for ease of maintenance and that offer long maintenance intervals will be preferred.

Benefits of High-Quality Slip Ring Housing

Opting for high-quality slip ring housing can provide several benefits that not only enhance operational efficiency but also contribute to reducing long-term costs. It’s an investment that ensures the optimal function of the slip ring assemblies and minimizes unexpected operational issues.

Increased Operational Lifespan:

High-quality housing materials and designs can significantly augment the lifespan of the slip ring assembly. Robust housings are more resistant to physical, thermal, and chemical stressors, ensuring that the internal components are well-protected for long-term usage.

Improved Electrical Performance:

A well-designed slip ring housing can contribute to better electrical performance by ensuring a stabilized environment for the transfer of power or signals. It minimizes electrical interference, ensuring accurate and consistent transmission.

Enhanced Protection Against Wear and Tear:

Quality housings are designed to protect the delicate slip ring assembly and brushes from wear and tear. They prevent the intrusion of dust and corrosive substances, reducing the mechanical wear of the rotating components.

Reduced Maintenance Costs:

With quality slip ring housing, the need for regular maintenance and part replacements can be drastically lowered, which translates into significant cost savings. Moreover, the reduced frequency of servicing also minimizes downtimes, thereby increasing operational productivity.

Improved Safety and Reliability:

Quality slip ring housings are designed to provide optimal safety, minimizing the risk of electrical shorts and other safety hazards. They assure reliable performance and longevity of the slip ring assembly, encouraging trust in the device’s operation even under demanding conditions.

Slip Ring Housing: Common Industry Applications

Slip ring assemblies enclosed inefficiently designed housings are part of numerous applications across a wide variety of industries. These components’ ability to offer continuous power transmission or signal exchange between stationary and rotating parts makes them invaluable. Here are some industry-specific applications:

Wind Turbines:

Wind turbines heavily rely on slip ring assemblies to transmit electrical power and data signals from the rotating turbine blades to the stationary generator. High-quality housings are essential to protect the assemblies against high rotational speeds, extreme weather conditions, dust, and corrosive sea air in offshore installations.

Robotics and Automation:

In the field of robotics and automation, slip ring housings are used extensively in rotating parts, like robotic arms, where they facilitate efficient power and data signal communication. They ensure robust operation, withstand mechanical stress, and minimize electrical noise, pivotal in maintaining the precision and reliability in automated processes.

Medical Systems:

Medical imaging devices such as MRI and CT scanners utilize slip ring assemblies to transfer power and signals from stationary parts to rotating components. The slip ring housings in these instances are typically designed to accommodate compact spaces, maintain a stable temperature, and avoid any electromagnetic interference that could compromise the image quality.

Military and Aerospace:

In the military and aerospace sectors, slip ring assemblies are essential for applications like radar systems, targeting systems, and space satellites. Given the severe operational conditions and high-reliability requirements, the chosen slip ring housings are often of the highest quality to protect against extreme environments, vibrations, and rapid fluctuations in temperature.

Maritime:

Marine applications include communication systems in ships, submarines, remotely operated sea vehicles, and offshore wind farms. Here, slip ring housings are designed to be waterproof and resist corrosion due to salt water, ensuring reliable operation while preventing water and moisture ingress.

Slip Ring Housing: Market Overview and Trends

The slip ring housing market forms a vital part of the slip ring industry that extends effortless power transmission in various sectors. Current advancements and future growth potential offer exciting developments in this field.

Current Market Trends and Innovations:

As technology advances, new trends, and innovations emerge in the slip ring housing market. One notable trend is the development of compact, high-performance slip ring housings, aligning with the industry’s miniaturization trend. Especially in areas like robotics and medical devices, compact housings that can efficiently fit into limited spaces while maintaining high performance are incredibly valuable.

Material innovation is another significant trend, with more durable, corrosion-resistant compounds becoming prevalent. The pursuit to enhance the longevity and reliability of slip ring assemblies has triggered the exploration and usage of materials like high-grade plastic, brass, and stainless steel for housings.

In terms of design, there is a growing trend towards custom-designed slip ring housings that cater to specific application requirements. This ensures optimal performance while extending the application lifespan.

Future Developments and Growth Potential:

The future of slip ring housing looks promising, facilitated by continuous technological evolution and the expanding range of applications. As industries such as renewable energy, automation, and space exploration continue to grow, so does the demand for advanced slip ring housings resistant to varied and extreme conditions.

Further, the advent of Industry 4.0 and the Internet of Things (IoT) provides new opportunities for innovation. Smart slip ring housings equipped with predictive maintenance capabilities can become a new avenue for growth, enhancing operational efficiency and reducing maintenance costs in various industries.

In summary, the slip ring housing market is expected to witness substantial progress and growth, driven by ongoing technological developments and growing demand from various industrial sectors.

Conclusion

The ability to select a suitable slip ring housing can significantly impact the efficiency and longevity of various machinery. By understanding its different aspects and making conscious decisions, you can ensure optimal performance and durability.

FAQs about Slip Ring Housing

Understanding the implications of slip ring housing choice is foundational to maximizing the longevity and performance of the slip ring system. Here, we address some of the most common questions that reflect the concerns of users.

Q: How does slip ring housing affect the lifespan of a slip ring?

A: The slip ring housing plays a vital role in preserving the operational lifespan of a slip ring. High-quality housing protects the slip ring assembly from physical stress, corrosion, dust intrusion, and other environmental factors, reducing the wear and tear of the assembly. Moreover, housing designed for optimal heat dissipation can prevent overheating, thereby extending the operational life of the slip ring.

Q: What kind of maintenance is required for slip ring housings?

A: Maintenance needs for slip ring housings depend on the application and operating conditions. Regular check-ups should involve inspection for any physical damage, corrosion, and dust buildup. Lubrication of bearings may be necessary in some cases. However, with high-quality slip ring housing, the need for high-frequency maintenance can be significantly minimized. Always refer to manufacturer recommendations for maintenance protocols to ensure optimal performance and longevity.

Q: How does the choice of housing material impact performance?

A: The choice of housing material can significantly influence the slip ring performance. Different materials offer varying degrees of durability, heat dissipation, corrosion resistance, and shielding against electromagnetic interference. For example, metal housings like stainless steel may provide better protection and heat dissipation but could be more susceptible to electromagnetic interference than plastic housings. Therefore, housing material choice should align with the specific application requirements and operating conditions.

See What We Can Do