This comprehensive guide aims to provide you with a detailed understanding of high RPM slip rings. We’ll explore their science, applications, how to choose them effectively, and trends shaping their future.

High RPM Slip Ring Introduction

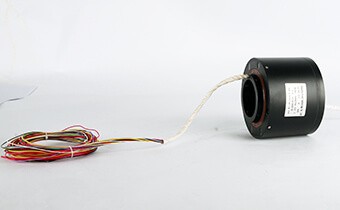

Slip rings, also referred to as rotational connectors, rotary electrical interfaces, or collectors, are devices engineered to transmit power, along with electrical and data signals, between fixed and rotating components within a system. The fundamental foundation of any slip ring is fairly straightforward: a series of rings are attached to a rotor, while brushes are connected to a stationary part of the system. When the rotor spins, the brushes maintain contact with the rings, thus enabling the continuous transfer of power or signals.

Slip rings find their utility rooted in numerous applications across industries. They play an instrumental role in providing continuous, uninterrupted connectivity to moving parts. Consider wind turbines, for example; slip rings ensure the smooth transmission of power from the spinning turbine blades to the stationary grid systems. Another critical application exists in medical scanning machines, where slip rings enable the rotation of scanning components to produce accurate and detailed imaging.

High RPM slip rings are particularly innovatively designed breeds within the slip ring family. They are structured to function at higher rotational speeds. These are special variants that can endure high rotations per minute (RPM) without compromising the efficiency of transmission or the longevity and durability of the overall device. Their design renders them invaluable in high-speed, high-performance requirements where reliability and efficiency, combined with high rotation, are primary requisites. The prevalence of high RPM applications in industries such as defense, renewable energy, telecommunications, and automation articulates the significance and necessity of high RPM slip rings.

In essence, high RPM slip rings are not just conventional slip rings capable of performing at high speeds, but they are engineering marvels tailored to withstand the rigors of high-speed operations while ensuring seamless communication between various system parts.

The Science Behind High RPM Slip Rings

At the core of any slip ring lies a simple concept – the transmission of electrical power and signals from a stationary structure to a rotating one. This is accomplished by a rotating assembly of conductive rings (the rotor) and fixed “brushes” that maintain contact with the rings. As the rotor turns, electric current or signals pass from the stationary brushes to the rotating rings and vice versa, enabling continuous power or signal flow despite motion.

High RPM slip rings, however, require an advanced level of design engineering due to the increased complexity associated with their high-speed operation. Firstly, high RPM slip rings must be resistant to the amplified impacts of centrifugal forces arising from faster rotations. To handle these conditions, the materials used for the rings and brushes have to be able to withstand high-speed friction and wear. Furthermore, designers must ensure the balance and alignment of the rotor to avoid anomalies that could lead to vibrations and premature component failure.

An additional critical feature of high RPM slip rings is the need for effective heat dissipation. Higher speeds generate increased heat due to friction, which must be effectively managed to prevent overheating and subsequent damage to the slip ring components. This is usually addressed by incorporating heat-resistant materials and advances in thermal management techniques into the design.

Moreover, reliable electrical contact between the rotating rings and stationary brushes must be ensured even at high rotational speeds. Minimizing noise and maintaining a low electrical resistance is essential for efficient signal and power transmission. Hence, the choice of contact material, brush pressure, and the surface finish of the rotating rings is of paramount importance.

In summary, suitable high RPM slip rings are a product of careful design considerations and material selection. They are built to resist the challenges of increased friction, heat generation, and wear while guaranteeing reliable and noise-free signal and power transmission even in high-speed rotational environments.

Key Applications of High RPM Slip Rings

High RPM slip rings find their applications in an array of industries demanding high-speed operations, reinforcing their omnipresence and significance. These sectors include but are not limited to, aerospace, military, renewable energy, industrial automation, marine applications, and even some areas within the entertainment industry.

Diving deeper into specific applications, one can comprehend the indispensability of high RPM slip rings. Consider wind turbines, for instance. These massive structures need to adapt to wind directions quickly and must be capable of functioning at high rotational speeds during periods of favorable wind conditions. Hence, wind turbines often incorporate high RPM slip rings to maintain steady power transmission from the rotor to the stationary components regardless of the wind speed.

In the aerospace and defense industries, high-speed testing facilities such as wind tunnels rely heavily on high RPM slip rings. These facilities need to simulate extreme flight conditions, including very high speeds, which are only feasible with slip rings that can withstand high RPMs. Similarly, in industrial automation, robotic arms often need to move at high speeds accurately, requiring the services of these high-performance slip rings.

Turning to real-world examples, the offshore wind farms represent a perfect illustration of high RPM slip rings in action. Offshore wind turbines, often subjected to strong and consistent winds, generate energy at high rotational speeds. The high RPM slip rings here ensure the steady transmission of generated power from turbines to the mainland.

Similarly, in military usage, cutting-edge radar systems rotate at very high speeds to provide near-instantaneous updates on aerial and naval threats. High RPM slip rings are the unsung heroes in these applications, conveying crucial power and data from the rotating radar antenna to the stationary processing units, and aiding in real-time threat evaluation.

Thus, while they may be unseen components, high RPM slip rings play an instrumental role in facilitating and strengthening the functions of several industries worldwide. Their ability to consistently operate in high-speed rotations not only brings a unique advantage but also underlines their irreplaceability in several operations.

Design and Materials of High RPM Slip Rings

When discussing design and materials incorporated into high RPM slip rings, two aspects stand at the forefront: longevity and performance efficiency. Both of these depend heavily on the choice of materials and the overall design structure.

Slip rings for high RPM applications often incorporate materials like precious metals, fiber optics, special alloys, and advanced composites. Precious metals, such as gold, silver, and palladium, are favored for their excellent electrical conductivity and resistance to corrosion. Similarly, fiber optics are commonly used where high-speed data transmission is required. Alloys and composites are chosen for their mechanical strength, heat resistance, and wear resistance – key factors for components operating in high RPM environments.

Apart from materials, the overall design also holds substantial importance. High precision in manufacturing, advanced assembly techniques, and the careful engineering of brushes and rings in such a way that they enable smooth contact – even at high speeds – are critical to the slip ring’s efficient operation.

Heat dissipation is indeed a significant concern for high RPM slip rings. Faster rotational speeds generate more heat due to increased friction, which can compromise the device’s lifespan and reliability. Material choices and design configurations must, therefore, address this concern. This typically means the use of materials with excellent thermal conductivity (to draw heat away from high-temperature zones) and possibly the integration of cooling systems into the design to maintain optimal operational temperatures.

High RPM environments naturally raise challenges regarding temperature management, friction control, and wear reduction. These are mitigated by deploying materials with high melting points and excellent thermal stability to counter high operational temperatures. Friction is managed by smoothing surfaces, fine-tuning brush pressures, and occasionally using lubricating materials to reduce wear. For dealing with wear, hard-wearing materials and regular maintenance schedules are instrumental in extending a slip ring’s operational lifespan.

In summary, the design and materials of high RPM slip rings are not merely random selections; they are meticulously chosen to ensure smooth, efficient operation, even in demanding, high-speed environments. Addressing heat dissipation, friction, and wear, though challenging, is foundational to enhancing performance and lifespan, underlining the need for continual innovation and development in this field.

Selection of High RPM Slip Rings

Choosing a high RPM slip ring is a decision that requires careful consideration of several key factors to ensure that the selected product aligns perfectly with the required application and expected performance.

At the top of the list is typically durability. High RPM operations can expedite wear and tear on even the sturdiest of materials, and users must thus evaluate the projected lifespan of the slip ring under expected working conditions. Not only is the inherent durability of a slip ring a factor—since it directly impacts the overall uptime of any system in which it’s installed—but also, broader life-cycle costs matter. These costs encapsulate not merely the initial purchase cost, but ongoing expenses related to maintenance, repairs, and eventual replacement.

Another concern for many users is the noise generated by the slip ring during operation. This could be particularly crucial in environments like hospitals or recording studios, where core activities are sensitive to noise. A high-quality slip ring for a high RPM application should exhibit minimized contact noise, reducing operational sounds considerably.

Beyond these functional aspects, potential purchasers also look into the quality standards that the slip ring meets, such as ISO or IEC. Certifications to these internationally recognized standards are often taken as indicators of overall product quality and reliability. Moreover, the reputation and track record of the manufacturer matters enormously. Reviews, endorsements, and long-term presence in the industry often signal better product and service quality, providing users with the assurance they seek when purchasing such a critical component.

Ultimately, selecting the right high RPM slip ring involves a careful, comprehensive evaluation of a variety of factors. Longevity, life-cycle cost, noise generation, quality standards, and manufacturer reputation all play pivotal roles in the process, ensuring that the selected product would seamlessly fulfill its role within a high-speed, high-performance operational setting.

High RPM Slip Ring Installation, Maintenance Practices, and Product Support

Often underestimated, correct installation and robust maintenance of high RPM slip rings are the key determinants of their operational uptime, performance, and product span.

When installing high RPM slip rings, users must follow the manufacturer’s guidelines meticulously. This includes optimum positioning to minimize stress on the component, required alignment of stationary and rotary interfaces, and accurate electrical interconnections to ensure system compatibility. Any missteps during installation can reduce the ring’s efficiency, leading to premature wear and tear or a potential system failure.

Maintenance of high RPM slip rings is vital. Regular inspections should be conducted to check for visible wear on the rings and brushes, alongside cleaning dust or debris that might affect performance. Additionally, checking for temperature anomalies, excessive vibrations, and irregular noise levels provides early indicators of potential issues. Crucially, maintenance needs to be preemptive rather than reactive, ensuring constant optimal performance and longevity of the rings.

In selecting slip rings, products with designs that minimize maintenance efforts should be favored. Such designs often feature easy-to-clean components, wear-resistant materials, and self-lubricating features. Over time, these types of products can yield substantial cost and time savings by reducing the frequency and duration of maintenance interventions.

Finally, no high RPM slip ring installation is entirely foolproof. Users, therefore, require robust product support from the manufacturer. Reliable technical support to troubleshoot issues, informative user manuals, and comprehensive training on product handling are invaluable. Furthermore, product warranties offer users peace of mind, reassuring users that the manufacturer stands behind their product and is willing to address any defects or issues that arise.

In conclusion, the process doesn’t end with picking and installing a high RPM slip ring. Regular, vigilant maintenance along with dependable product support is equally integral to ensure that these crucial components deliver their optimal performance throughout their lifespan. It’s through this holistic approach that users can reap the full advantages offered by high RPM slip rings.

Emerging Trends in High RPM Slip Rings

In the dynamic and ever-evolving field of slip rings, technology trends aim to address user concerns and increase the efficiency and sustainability of high RPM slip rings.

Design and material advances are increasingly focusing on enhancing durability and reducing noise levels in high RPM slip rings. The use of special alloys and advanced composites has been on the rise to create more robust structures that can withstand high speeds and rapid temperature changes. Meanwhile, novel design elements like innovative brush configurations and improvements in contact materials are being incorporated to ensure smoother contact at higher rotational speeds, thereby reducing noise levels.

Heat dissipation, a critical concern for high RPMs, is also gaining attention in recent advancements. Progress in thermal management, including the integration of cooling systems within the slip ring design, and the use of materials with excellent thermal conductivity, is becoming more common. Similarly, one can observe a growing trend towards slip ring designs that use composite and thermally resistant materials to improve overall heat resistance and dissipation.

Looking towards the future, various trends like the advancement in material science can be set to reshape the landscape for high RPM slip rings. For instance, the exploration of nano-enhanced materials presents a significant potential to improve slip ring characteristics. These materials, recognized for their remarkable strength, thermal stability, and electrical conductivity, could be critical for longer-lasting, more efficient slip rings.

Additionally, advances in intelligent maintenance practices through the use of IoT and predictive analytics are likely to make inroads into the realm of high RPM slip rings. AI-enabled predictive maintenance could forecast potential mechanical problems before they occur, ensuring timely interventions that enhance the operational uptime and longer lifespan of these slip rings.

In a nutshell, the future for high RPM slip rings brims with promise and exciting possibilities. As technology progresses and advances in this field continue to unfold, it’s reasonable to anticipate even more sophisticated, reliable, and efficient high RPM slip rings that will further consolidate this vital component’s indispensability.

Looking for reliable High RPM Slip Rings? Contact us today to get a free quote.

Conclusion

High RPM slip rings, with their pivotal role in numerous sectors, are continually innovating to address the users’ primary concerns. Achieving the right balance between initial and running costs, and performance, and addressing factors such as durability, noise, and heat management is of paramount importance. By understanding these elements and the emerging trends, users can make informed decisions that maximize the benefits derived from these sophisticated devices.