Slip rings are devices that transmit electrical power and signals from a stationary to a rotating structure. There are basically two parts in them and the slip ring working principle and their action is pretty simple to understand if one has the basic concept of physics. So let’s dive into the topic of how do slip rings work without any further ado.

What Is A Slip Ring

A slip ring is an electromechanical device that allows the transmission of electrical power and signals from a stationary structure to a rotating one. Here are some key points about slip rings:

- Functionality: Slip rings enable the continuous rotation of equipment while transmitting power and data, which is essential in various applications where rotation is required without disrupting the electrical connection.

- Structure: A typical slip ring consists of a rotating ring and stationary brushes. The ring is usually mounted on the rotating part of the machinery, while the brushes remain stationary. As the ring rotates, the brushes maintain contact, allowing electricity to pass through.

- Customization: Many slip rings can be customized to meet specific requirements, such as the number of circuits, voltage, current capacity, and environmental conditions (e.g., waterproof or dustproof designs).

Slip rings are essential components in any system where rotational motion and electrical transmission are needed simultaneously. Their design and functionality allow for continuous and reliable operation in various industrial and commercial applications.

Different Type of Slip Rings And Their Working Mechanism

Slip rings are essential components used to transmit electrical currents or signals from a stationary to a rotating part. Understanding the different types of slip rings and their working mechanisms is crucial for selecting the right type for specific applications. Here, we discuss brush slip rings, brushless slip rings, and fiber optic slip rings.

Brush Slip Rings

Working Mechanism:

- Components: Consist of conductive rings mounted on a rotating shaft and stationary brushes that make contact with these rings.

- Transmission: Electrical currents or signals are transmitted through the brushes that physically contact the rotating rings.

- Wear and Maintenance: Over time, the brushes wear out due to friction and need to be replaced periodically to maintain reliable transmission.

Applications:

- Cranes: To transmit power and control signals to rotating components.

- Wind Turbines: To transfer electrical signals from the rotating blades to the stationary system.

- Elevators: To ensure continuous power and signal transmission between moving and stationary parts.

Brushless Slip Rings

Working Mechanism:

- Components: Utilize electromagnetic or radio frequency (RF) transmission methods instead of physical brushes.

- Transmission: Electrical currents or signals are transmitted through electromagnetic fields or RF signals, eliminating the need for physical contact.

- Durability: Without brushes, these slip rings are more durable and have a longer lifespan as there is no wear and tear from friction.

Applications:

- High-Speed Rotating Systems: Where long-lasting and low-maintenance components are crucial.

- Aerospace and Defense: For systems requiring reliable and durable transmission under harsh conditions.

Fiber Optic Slip Rings

Working Mechanism:

- Components: Use fiber optic cables to transmit data instead of electrical signals.

- Transmission: Electrical signals are converted into light signals, transmitted through the fiber optic cables, and then converted back into electrical signals at the other end.

- High-Speed Data: Ideal for applications requiring high-speed or high-bandwidth data transmission.

Applications:

- Medical Imaging Equipment: Such as CT scanners, where high-resolution data transmission is essential.

- Communication Systems: For high-speed data transfer without interference.

- Military Applications: Where secure and fast communication is required.

Try Grand Slip Rings Now!

🔒Have specific slip ring requirements? Submit your inquiry here.

Applications of Slip Ring

Slip rings have a wide range of applications across various industries due to their ability to transmit power and signals in rotating systems. Here are some common applications:

- Wind Turbines: Slip rings are used to transfer power and signals between the nacelle and the rotating blades. They are crucial for the efficient operation of wind turbines, enabling the transfer of data for monitoring and control systems.

- Medical Equipment: In medical devices like CT scanners and MRI machines, slip rings allow the continuous rotation of the imaging apparatus while transmitting data and power, ensuring high-quality imaging and operational efficiency.

- Radar Systems: Slip rings are used in radar systems to transmit signals and power between the stationary and rotating parts of the radar, facilitating continuous 360-degree scanning.

- Cranes and Construction Machinery: Slip rings enable the transmission of power and control signals to the rotating parts of cranes and other construction machinery, allowing for seamless operation of lifting and rotating mechanisms.

- Robotics: In robotic arms and other rotating robotic systems, slip rings are used to transmit power and control signals, enabling smooth and precise movements.

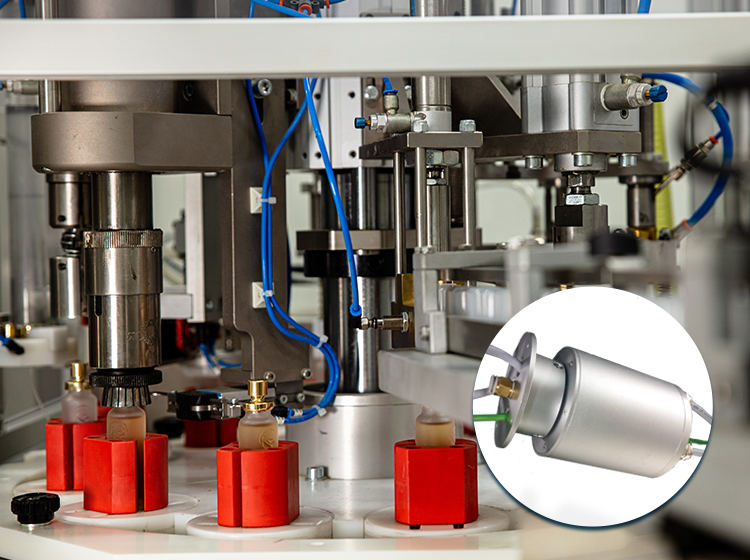

- Packaging machinery: Slip rings in packaging machinery ensure the continuous rotation of components while transmitting power and control signals, essential for automated packaging processes.

- Rotary Tables: Slip rings are used in rotary tables for machining and manufacturing processes, allowing for the transmission of power and signals to the rotating table while maintaining continuous operation.

- CCTV and Surveillance Systems: Slip rings in pan-tilt-zoom (PTZ) cameras allow continuous rotation of the camera while transmitting video signals and power, ensuring comprehensive surveillance coverage.

- Aerospace and Defense: In aerospace and defense applications, slip rings are used in gyroscopes, antenna systems, and other rotating equipment, facilitating reliable transmission of power and data.

- Amusement Rides: Slip rings in amusement rides enable the transfer of power and control signals to rotating parts, ensuring safe and continuous operation of the rides.

- Oil and Gas Drilling: Slip rings are used in drilling rigs to transmit power and control signals to rotating drill equipment, enabling efficient drilling operations.

- Marine Equipment: In marine applications, slip rings are used in rotating radars, winches, and underwater vehicles, providing reliable power and signal transmission in harsh marine environments.

These applications demonstrate the versatility and critical importance of slip rings in enabling continuous rotation and reliable transmission of power and signals across various industries.

How to use slip rings?

To use a slip ring, the general maneuver that has to be followed is explained below:

Determining the type of slip ring required: There are several types of slip rings, including brush slip rings, brushless slip rings, and fiber optic slip rings. Choose the type of slip ring that is most suitable for the specific application and requirements.

Install the slip ring: Follow the manufacturer’s instructions to install the slip ring on the stationary and rotating components. Make sure the slip ring is properly aligned and tightened to ensure a secure and reliable connection.

Connect the electrical power or signals source: Connect the stationary part of the slip ring to the electrical power or signals source, following the manufacturer’s instructions.

Connect the rotating component: Connect the rotating part of the slip ring to the component that needs to be powered or have signals transmitted to or from it, following the manufacturer’s instructions.

Test the slip ring: Once the slip ring is installed and connected, test it to ensure that it is functioning properly and transmitting the electrical power or signals as intended.

Perform regular maintenance: Regular maintenance and inspection of the slip ring can help ensure its proper functioning and extend its lifespan. Follow the manufacturer’s

In most cases, the use of slip rings requires no special permission. However, if you are planning to use slip rings in a commercial product or application, it is important to ensure that you are complying with any relevant safety and regulatory standards. For example, in certain parts of the world, slip rings used in electrical equipment must meet the requirements of safety agencies such as Underwriters Laboratories and the Canadian Standards Association. Additionally, you may need to obtain any necessary approvals or certifications from these agencies before you can sell or distribute your product.

Noteworthy points on factors that affect how does a slip ring work

It is also worth noting that some industries may have specific requirements for the slip ring working. For example, slip rings used in aerospace or military applications may need to meet additional standards or undergo additional testing to ensure their reliability and performance. If you are planning to use slip rings in a specialized application, it is a good idea to research the specific requirements and obtain any necessary approvals or certifications before proceeding.

The weight of a slip ring depends on a variety of factors, including its size, materials, and design. Slip rings are available in a range of sizes and configurations to suit different applications, and their weights can vary significantly as a result.

In general, smaller slip rings tend to be lighter than larger ones. For example, a slip ring with a diameter of 1 inch (2.54 cm) might weigh a few ounces, while a slip ring with a diameter of 6 inches (15.24 cm) could weigh several pounds. The materials used in the construction of a slip ring can also affect its weight. Slip rings are typically made from metal, such as copper or aluminum, which are relatively dense materials. Slip rings made from other materials, such as plastic or ceramic, may be lighter in weight.

It is also worth noting that slip rings can be designed for different performance and durability requirements, which can affect their weight. For example, slip rings designed for high-speed or high-voltage applications may have heavier components or additional layers of insulation to ensure their reliability and safety.

Overall, the weight of a slip ring can vary significantly depending on its size, materials, and design. It is important to choose the right slip ring for your application, taking into account the weight and other factors that may be relevant to your specific needs.

That ends our discussion about the topic ‘how do slip rings work’. Futuristic models are being made and in the same way, futuristic articles are also being pumped out from our side. So adieu for now as we decide upon meeting with the same enthusiasm on yet another topic.