Gain in-depth insights into the pivotal role of multi-channel slip rings in various industries. From its basic definition, key considerations, and technical specs, to futuristic trends, this guide gives you a complete understanding of these components, empowering you to make an informed selection for your project.

Introduction to Multi-Channel Slip Ring

At its most basic, a slip ring is a form of rotating electrical connector – a device that enables the transfer of power or data across rotating interfaces. But as technology has advanced, so too have the capabilities of slip rings, leading us to the pivotal solution of multi-channel slip rings. This particular type of slip ring has an added layer of complexity and functionality – not only does it allow for the transfer of electricity or data, but it also does so across multiple channels, making it simultaneously more efficient and specialized.

The significance of multi-channel slip rings stretches across scores of industries. Thanks to their ability to separately and independently handle multiple data and power connections, they have become an integral part of many modern machinery and complex systems. Whether it’s the robotics industry where they play a critical role in the operational efficiency of robotic arms, or medical science where they’re an essential component of advanced imaging devices, multi-channel slip rings have proved their indispensability.

In the realm of renewable energy, too, their application is growing steadily. Consider wind turbines, for example, wherein multi-channel slip rings actively contribute to their smooth functioning by transferring power and data from the motionless base to the rotating generator. Even in the different facets of military and defense applications, such as radar systems and turret gun controls, multi-channel slip rings demonstrate their fundamental role.

In summary, multi-channel slip rings with their complex but efficient functionality act as an indispensable element in an expansive range of industries, catering to an array of applications by facilitating effective and uninterrupted power and data transmission.

Understanding Multi-Channel Slip Rings

At the foundation of understanding the world of slip rings, multi-channel slip rings emerge as a crucial concept. To put it simply, multi-channel slip rings are electromechanical devices designed to transfer electrical power and data signals over multiple channels from a stationary to a rotating structure, all in one go. This unique attribute essentially means that instead of just a single line of data or power passing through, these slip rings can simultaneously handle multiple independent lines. These devices are the key to achieving multi-faceted and efficient communication between stationary and rotationally dynamic platforms without the tangling of wires.

The mechanism of a multi-channel slip ring comprises several core components that harmoniously work together. Central to this configuration are the rotor, the stator, and the brushes. The rotor is the rotating part of the device and typically carries the data or power from the source. The brushes, made from metal or similar conductive materials, maintain electrical contact with the rotor. They act as the link between the stationary part of the device and the rotating part, transferring the signals or power they receive from the stator to the rotor.

On the other hand, the stator as the stationary component of the assembly, serves as the platform where the signals or power from an external source land initially. It then passes this input to the brushes, which further passes it on to the rotor. This harmonious interplay between the rotor, stator, and brushes allows the multi-channel slip ring to maintain a constant flow of multiple data and power lines simultaneously from a stationary source to a rotating recipient.

Given this intricate operation, it is clear how multi-channel slip rings stand as a game-changing solution to handling different power and data lines. Their architectural charm lies in the intricacy of their design, which allows multiple streams of inputs to flow without interference and in a compact unit.

Applications of Multi-Channel Slip Rings

The applications of multi-channel slip rings stretch across a wide array of fields, showcasing their versatility and essential utility in many of today’s technological and industrial advancements. From the core of heavy industrial machinery to the delicate intricacies of medical devices, they play a pivotal role in enabling complex systems to operate smoothly and efficiently. Robotics, marine technology, and advanced surveillance systems are also notable fields where the multifaceted capabilities of multi-channel slip rings are employed to great effect.

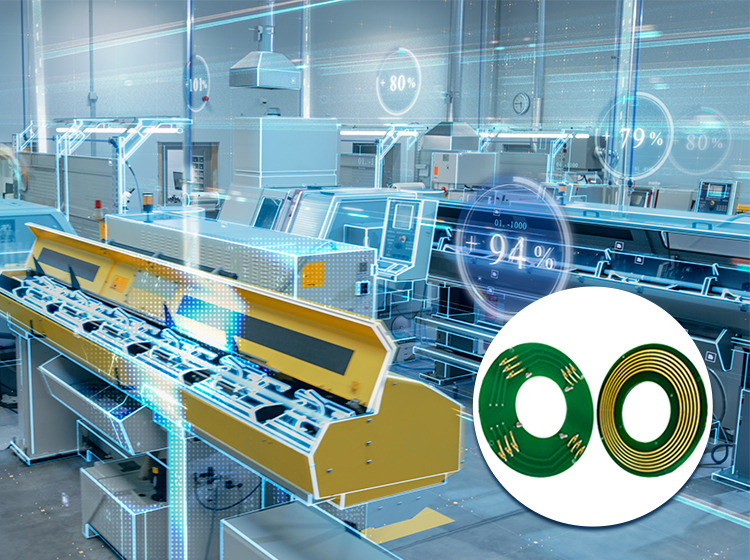

In the realm of industrial machinery, multi-channel slip rings are indispensable in facilitating automation and control processes. For example, in large manufacturing plants, assembly machines utilize these devices to maintain a constant stream of power and data signals across rotating parts, ensuring uninterrupted production lines that are essential for efficiency and reliability.

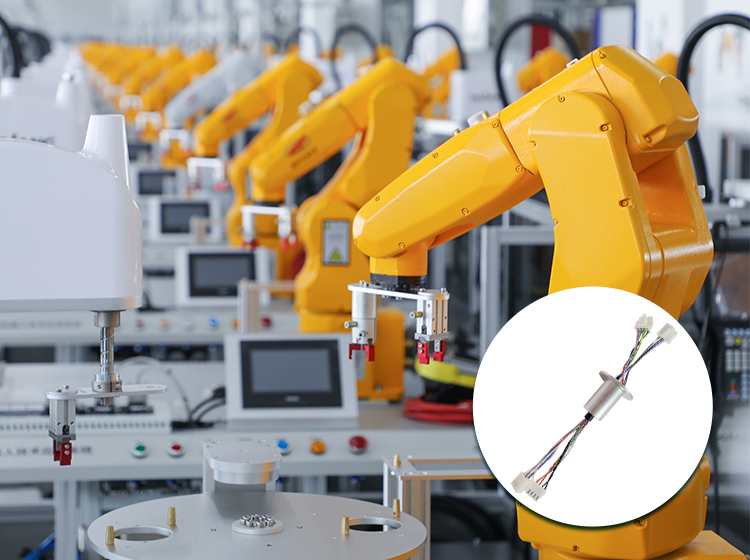

In the field of robotics, the articulate movements of robotic arms, especially those employed in precision tasks such as assembly in electronics manufacturing or surgical procedures in medical robotics, rely heavily on multi-channel slip rings. These devices empower the robots with the ability to receive power and transmit data simultaneously across different channels without interference, allowing for precise control and feedback in real-time.

The marine industry benefits from the use of multi-channel slip rings in various navigational and operational systems aboard ships and underwater equipment. Submersibles, for instance, use these slip rings to ensure that they can send back crucial data to the surface while receiving power and operational commands. This capability is critical for deep-sea exploration missions, where the reliable transfer of multiple data types back to the control center is essential for both the success of the mission and the safety of the equipment.

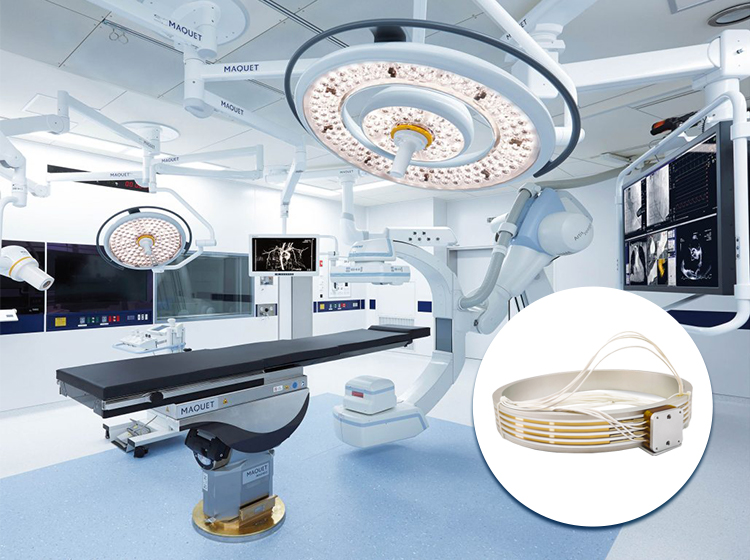

In the medical field, advanced imaging devices like MRI machines utilize multi-channel slip rings to facilitate the transfer of power and high-fidelity data between the stationary and rotating parts of the scanner. This ensures that patients can be scanned with high precision, leading to better diagnostic capabilities and patient outcomes.

Surveillance systems, especially those that require the constant rotation of cameras for 360-degree coverage, depend on multi-channel slip rings to operate effectively. These devices allow for the continuous rotation of the camera systems without the risk of tangled wires, ensuring that data and power supply remain uninterrupted. In situations where security is paramount, the reliability provided by these slip rings ensures that no blind spots are left unmonitored.

These examples underscore the utility and versatility of multi-channel slip rings across various domains. Their ability to enable complex, multi-faceted operations across a suite of different technologies and industries illustrates their critical role in modern systems. Whether it’s in the depth of the ocean, the precision of medical diagnostics, the robustness of industrial machinery, or the agility of robotic systems, multi-channel slip rings stand as a testament to the intricate interplay of power and data that drives the modern world.

Multi-Channel Slip Ring: Key Features and Design Considerations

When approaching the unique world of multi-channel slip rings, it’s crucial to recognize the features that truly set them apart. Among these critical characteristics, the number of channels, signal compatibility, and bandwidth provision are key.

The most fundamental feature of a multi-channel slip ring is, as the name implies, the ability to incorporate multiple channels. This feature allows the simultaneous handling of multiple independent circuits, carrying different power and data signals without interference. This multi-faceted functionality is particularly useful in systems that require numerous simultaneous connections, resulting in efficient and seamless operations.

Signal compatibility is another essential feature. A high-quality multi-channel slip ring must be capable of handling various signal types, from high-speed data signals in advanced communication systems to different power levels needed in mechanical operations. This compatibility enables these slip rings to be employed across a wide range of systems and industries without hindrance.

Bandwidth, an important factor to consider, refers to the maximum data transfer rate of a network or internet connection. In multi-channel slip rings, provision for large bandwidth ensures the efficient transmission of high volumes of data in advanced technological systems.

Once the main features are understood, it is essential to pivot attention towards crucial design considerations, including size, material selection, durability, and maintenance prospects. The size of a multi-channel slip ring often depends on the space constraints of its intended application. For instance, in compact environments like drones or small medical devices, miniaturized slip rings are preferred without compromising the performance.

Material selection is also a critical consideration and varies based on the conditions of the operating environment. For instance, in corrosive or harsh environments, materials resistant to corrosion and high temperatures, such as gold or certain alloys, might be the go-to choice to ensure longevity and reliable performance.

Durability is a non-negotiable trait of any well-designed multi-channel slip ring, particularly those employed in rigorous environments or devices requiring continuous operation. Their robust construction, combined with the right materials, can effortlessly meet this requirement.

Maintenance prospects closely rely on the operating environment and application requirements. However, it’s common to design multi-channel slip rings to be as low-maintenance as possible. This involves incorporating features like long-life brushes and sealed housing to protect against dust and moisture.

In essence, through the lens of key features and design considerations, one can truly appreciate the complexity, versatility, and attention to detail that shapes the realm of multi-channel slip rings. It involves a delicate balance between incorporating intricate features and making thoughtful design considerations that cater to a wide array of applications and operating conditions.

Multi-Channel Slip Ring: Technical Specifications

Navigating through the diverse offering of multi-channel slip rings requires one to be well-versed in the critical technical specifications that can significantly influence performance. The primary specifications that users often need to examine include the electrical and signal characteristics, insulation strength, contact materials, and rated speed.

Electrical and signal characteristics encapsulate key parameters such as voltage rating, current rating, and signal compatibility. The voltage rating defines the maximum voltage the slip ring can handle, and the current rating refers to the maximum current it can conduct. These ratings ensure that the slip ring can safely handle the electrical loads in its intended application. Signal compatibility entails the types of data signals the slip ring can transfer—such as digital, analog, or Ethernet—depending on the application’s needs.

Insulation strength is a crucial spec as it relates to the resistance offered against electrical breakdown. High insulation strength ensures that the different channels within the slip ring can operate simultaneously without cross-interference, maintaining the integrity of both the power and data being transferred.

Contact materials play a definitive role in the performance and life span of the slip ring. Commonly used materials include precious metals like gold or silver, known for their excellent conductivity and low resistance. The right choice of contact material can not only assure effective signal transmission but can also minimize wear and hence extend the service life of the device.

Rated speed signifies the maximum rotational speed that the slip ring can safely operate at without potential damage or substantial wear. This attribute needs to be in sync with the operational speed of the rotating platform where the slip ring is installed.

Understanding these technical specifications helps users find a multi-channel slip ring that aligns with their requirements. But beyond the specifications themselves, the chosen slip ring must be compatible with its intended application. This means that in addition to the power and signal types the slip ring needs to handle, users should also consider the operating environment. For example, slip rings used in outdoor or marine environments should be able to withstand moisture, while those used in space applications should endure vacuum conditions.

In essence, selecting the right multi-channel slip ring based on technical specifications is an integral process coupling knowledge about crucial technical aspects with an accurate understanding of the intended application’s conditions and needs. By doing so, users can ensure they are choosing a slip ring with the right attributes to deliver optimal performance in their specific application, promoting operational efficiency and reliability.

Multi-Channel Slip Ring: Installation and Maintenance

The installation and maintenance of multi-channel slip rings are critical processes that directly influence their performance, longevity, and reliability. Understanding the nuances of these tasks can help users navigate the common challenges and uphold the operational integrity of their systems.

Installation Process

The installation of a multi-channel slip ring necessitates a careful approach, considering several potential challenges such as alignment issues, electrical compatibility, and environmental protection.

- Alignment: Accurate alignment of the slip ring with the rotating component is crucial. Misalignment can lead to uneven wear, increased electrical noise, or even failure. Using precision tools and following manufacturer guidelines can help assure proper alignment.

- Electrical Compatibility: Ensuring the slip ring’s electrical specifications match those of the system it is integrating with is vital to prevent overload, short circuits, or improper signaling. Double-check voltage, current ratings, and signal type compatibility before installation.

- Environmental Protection: If the slip ring is to operate in challenging environments – be it high humidity, dust, or corrosive atmospheres – taking steps to protect it through appropriate housings or sealants is essential.

Addressing these challenges requires meticulous planning and adherence to the manufacturer’s installation instructions. Whenever possible, consulting with a technical expert or the slip ring manufacturer can provide tailored advice and solutions.

Maintenance Best Practices

The key to extending the life and reliability of multi-channel slip rings lies in regular and proactive maintenance. The focal points of an effective maintenance regime include inspection, cleaning, and lubrication.

- Regular Inspection: Schedule periodic inspections to check for wear and tear, misalignment, or electrical integrity issues in contacts and wires. This proactive approach helps in identifying potential problems before they lead to system failure.

- Cleaning: Accumulation of dust, debris, or other contaminants on the slip ring contacts can cause poor electrical conductivity and increased wear. Gentle cleaning with appropriate solutions recommended by the manufacturer, followed by drying, can mitigate these issues. It’s critical to ensure that the cleaning agents are compatible with the materials of the slip ring to avoid damage.

- Lubrication: Some slip rings may require lubrication to reduce friction and wear. However, this is highly dependent on the slip ring’s design and the materials used. If lubrication is necessary, use only the type recommended by the manufacturer and apply it sparingly to prevent attracting dust or creating buildup that could impede performance.

Consistent adherence to these maintenance practices ensures that multi-channel slip rings operate efficiently and reliably, thus protecting the investment made in these complex components. Documentation of routine inspections and any corrective actions taken can also assist in maintaining a clear history of the device’s performance and maintenance, which is beneficial for troubleshooting and future planning.

Multi-Channel Slip Ring: Challenges and Troubleshooting

While multi-channel slip rings are engineered to facilitate seamless power and data transmission in rotating interfaces, users may occasionally face challenges that can impact performance. Identifying these challenges early and understanding how to troubleshoot them is key to avoiding system downtime and ensuring the longevity of the slip rings.

Common Challenges

- Signal Interference: One of the most prevalent issues with multi-channel slip rings is electromagnetic interference (EMI), which can disrupt signal integrity. This could be due to improper shielding, proximity to other electronic devices, or cross-talk between channels.

- Wear and Tear: Mechanical wear is an inevitable consequence of the moving parts within a slip ring. Excessive wear can lead to degraded electrical contact, resulting in fluctuating signals or power loss.

- Environmental Impact: Environmental elements such as moisture, salt spray, dust, or extreme temperatures can adversely affect slip ring operation. Corrosion, insulation breakdown, and material degradation are potential outcomes that could arise from such exposure.

Troubleshooting Tips and Solutions

- Addressing Signal Interference:

- Verify proper shielding of the slip ring and the cabling connected to it.

- Check the installation for proper grounding to reduce EMI.

- Assess the design to ensure there’s sufficient distance or separation between power and signal lines to minimize cross-talk.

- For troubleshooting complex EMI issues, consulting with the manufacturer or utilizing spectrum analyzers to identify the source of interference may be necessary.

- Mitigating Wear and Tear:

- Conduct regular inspections for signs of deterioration, focusing on contact materials and brushes.

- Verify that the rated speed and current ratings are not exceeded, as surpassing these limits can accelerate wear.

- If wear is detected, consult with the manufacturer on the best course of action, which may involve replacing worn components or adjusting operating parameters.

- Combating Environmental Impact:

- Ensure the slip ring is rated for the specific environment it’s operating in. For example, using a slip ring with an appropriate IP (Ingress Protection) rating for dusty or wet conditions.

- Implement preventive measures such as environmental sealing or the use of protective covers if necessary.

- Regular cleaning and maintenance help preserve the integrity of the slip ring when exposed to harsh conditions.

The Importance of Manufacturer Support and Documentation

Effective troubleshooting relies heavily on manufacturer support and the technical documentation provided with the slip ring. These resources contain crucial information like detailed specs, installation guides, maintenance schedules, and specific recommendations for addressing the operational challenges mentioned above. When issues arise that fall outside the scope of general troubleshooting, contacting the manufacturer is often the best course of action. They can offer expert advice, diagnostic tips, and sometimes on-site assistance to resolve the problem.

Manufacturers may also provide training or online support resources that can enhance the user’s ability to maintain and troubleshoot slip rings effectively. Keeping a complete set of documentation accessible for all operational and maintenance staff ensures that information is readily available for quick decision-making and problem resolution.

In summary, a proactive approach to recognizing challenges and systematically addressing them through troubleshooting measures—backed by comprehensive documentation and manufacturer support—can significantly enhance the performance, reliability, and life expectancy of multi-channel slip rings.

Multi-Channel Slip Ring: Future Trends and Innovations

The landscape of multi-channel slip ring technology is continuously evolving, driven by advancements in engineering, materials science, and the growing demands for smarter, more efficient systems. Emerging trends and innovations promise not only to enhance the performance and durability of these essential components but also to expand their application scope significantly across various industries.

Emerging Trends in Multi-Channel Slip Ring Technology

- Integration of Wireless Communication: One of the most exciting innovations is the integration of wireless communication capabilities within slip rings. This feature allows for real-time data transmission without physical contact, reducing wear and tear and improving the reliability of data transfer in critical applications.

- Smart Monitoring Features: The implementation of sensors and monitoring systems within slip rings enables predictive maintenance capabilities. By continually assessing the condition of the slip ring, such as monitoring wear levels, temperature, and electrical performance, these smart features can alert operators to potential issues before they result in system failure, thereby minimizing downtime.

- Advancements in Materials Science: Progress in materials science has led to the development of new contact materials and coatings that offer improved electrical performance and resistance to environmental factors. These advancements promise to extend the life span of slip rings and allow their use in more extreme conditions, such as in space exploration or deep-sea applications.

Potential Impact of Innovations

The integration of these innovations is set to have a profound impact on the performance, durability, and versatility of multi-channel slip rings.

- Enhanced Performance: With wireless communication and advanced contact materials, slip rings can achieve higher data transmission rates and improved electrical performance. This enables their use in applications requiring fast, reliable communication between rotating and stationary parts, such as in advanced robotics and high-speed data acquisition systems.

- Increased Durability: The application of new materials and smart monitoring features can significantly enhance the durability of slip rings. By reducing wear and preventing potential failures before they happen, these innovations extend the operational life of slip rings, making them more cost-effective and reliable over time.

- Expanded Application Scope: The advancements in slip ring technology open up new possibilities for their use in various sectors. For example, slip rings with enhanced resistance to extreme environments can be employed in space satellites, underwater robotics, or in harsh industrial processes. Similarly, the integration of cutting-edge communication methods extends their applicability to fields requiring high-precision, real-time data exchange.

In conclusion, the ongoing innovations in multi-channel slip ring technology are not just improvements on existing designs; they represent a significant shift towards more reliable, efficient, and versatile systems. As these technologies continue to evolve and mature, we can expect to see slip rings play increasingly critical roles in a broad range of applications, pushing the boundaries of what’s possible in both existing and new industries. The future of multi-channel slip rings is one of expansion and exploration, as technological advancements redefine their potential and utility.

Selecting the Right Multi-Channel Slip Ring

Choosing the right multi-channel slip ring can significantly impact the performance and reliability of rotational equipment. Considering crucial factors such as manufacturer reputation, support services, customization options, and balancing cost with quality and functionality can help users make an informed choice.

Factors to Consider When Selecting a Multi-Channel Slip Ring

- Reputable Manufacturers: Selecting a manufacturer with a proven track record in the industry is essential. A reliable manufacturer will often display consistent quality, and reliability, with proven use cases in various industries. Reviews, testimonials, and case studies can provide valuable insights into a manufacturer’s performance and credibility.

- Support Services: Manufacturers that offer comprehensive after-sales services, such as installation assistance, maintenance guides, and troubleshooting support, should be given preference. These services can significantly impact the longevity and performance of the slip ring.

- Customization Options: Depending on the specific requirements of your application, custom solutions may be necessary. Confirm whether the manufacturer can accommodate these necessities. Customization might involve altering the material, size, and number of channels, or integrating additional features like sensors or wireless communication capabilities.

Balancing Cost with Quality and Functionality

The right slip ring isn’t always the cheapest or the one with the most features. Instead, it should be a balanced selection, considering the specific needs of your application, the quality of the product, and its cost.

High-quality slip rings might be expensive upfront but can provide better performance, less downtime, and longer service life, thereby offering better value over time. Functionality should align with application requirements; opting for models with unnecessary features might increase costs without any tangible benefit.

On the other hand, settling for low-cost options could mean compromising the quality or durability of the slip ring, potentially leading to frequent replacements or system failures.

Importance of Meeting Application Needs

At the heart of the selection process is meeting the needs of the specific application. The operational conditions, frequency of use, environmental factors, and transmission requirements (power, data, or both), should guide your choice of multi-channel slip ring. By aligning your selection with your application requirements, you can ensure not only the compatibility of the slip ring with your system but also its performance and service longevity.

In conclusion, choosing the right multi-channel slip ring is a balance of various factors. Assessing the reputation and support services of the manufacturer, understanding your own specific needs, and carefully weighing the cost against quality and functionality are all integral to a successful selection process. A thoughtful choice ensures reliable operation, extends equipment lifespan, and mitigates potential issues, securing your investment in the long run.

Conclusion

Multi-channel slip rings remain deeply intertwined with modern industrial and technology applications. It’s crucial to consider how they operate, their key attractions, potential issues, and future developments while making a selection for your device. Such comprehensive understanding fosters wiser choices, thereby optimizing machine performance.

FAQs about Multi-Channel Slip Ring

Below are commonly asked questions about multi-channel slip rings, each accompanied by an informative answer to guide users in understanding and optimizing the use of these complex devices.

Q1: What is a multi-channel slip ring, and how does it work?

A1: A multi-channel slip ring is an electromechanical device designed to transfer power, data, and signals from a stationary part to a rotating one, allowing for 360-degree continuous rotation. Each ‘channel’ refers to an individual electrical path; multi-channel slip rings have multiple paths to transfer different types of signals or power concurrently. They work using conductive rings connected to the rotating shaft and brushes that maintain electrical contact with the rings as the shaft turns.

Q2: How do I select the right multi-channel slip ring for my application?

A2: Selecting the right slip ring depends on various factors, including the types of signals or power to be transmitted, the required number of channels, rotational speed, operating environment, and space constraints. It’s important to work with reputable manufacturers who can offer support and customization options to tailor a slip ring to your specific needs. Balancing cost with functionality and quality is also crucial to ensure that the slip ring can meet your application requirements without unnecessary features.

Q3: What are the signs that a multi-channel slip ring needs maintenance or replacement?

A3: Signs that a multi-channel slip ring requires maintenance include erratic signal quality, fluctuations in power transmission, visible wear and tear on the brushes or rings, or increased electrical noise. Regular maintenance schedules should be adhered to, and if these signs persist despite maintenance, it might be time to consult the manufacturer for potential replacement.

Q4: Can multi-channel slip rings operate in harsh environments?

A4: Yes, multi-channel slip rings can be designed to operate in harsh conditions, including extreme temperatures, high levels of vibration, dust, moisture, and corrosive elements. Specialized slip rings with the appropriate Ingress Protection (IP) ratings, sealing, and durable materials are available for such demanding applications.

Q5: Are there any innovations in slip ring technology that I should be aware of?

A5: Recent innovations in slip ring technology include the integration of wireless communication to minimize wear and tear, smart monitoring features that allow for predictive maintenance, and advances in materials science leading to more durable and efficient designs. These trends are enhancing performance and expanding the applications in which slip rings can be effectively utilized.

Q6: How does electrical noise affect a multi-channel slip ring, and how can I minimize it?

A6: Electrical noise can cause signal interference and data transmission errors. To minimize noise, ensure that the slip ring has proper shielding and grounding. Choosing slip rings manufactured with precision and low-resistance materials can also reduce electrical noise. If issues persist, it may be beneficial to consult with the manufacturer for specific solutions catered to your system’s configuration.

See What We Can Do