In today’s increasingly connected digital world, rotary cable connectors play a pivotal role. This article offers a comprehensive understanding of these components, shedding light on their design, selection criteria, common applications, leading suppliers, and future development trends.

Rotary Cable Connector Introduction

In the sophisticated ecosystem of modern engineering and technology, complexity often lies within the smallest components. One such component operating behind the scenes to keep systems functioning seamlessly is the rotary cable connector. Essentially, these are electromechanical devices designed to transmit power, signals, or data between stationary and rotating components within a system.

Rotary cable connectors find themselves at the heart of various applications spanning diverse industries, from telecommunications and renewable energy to aerospace and automation. Their primary role is to ensure stability in the flow of data or power, thus maintaining the integrity of the systems they support.

The fundamental importance of rotary cable connectors lies in their ability to enable continuity and rotational movement without causing disruption or loss in the transmission. Moreover, they have specific designs adapted to sustain the different environmental conditions and mechanical stresses they may encounter, depending on the industry in which they operate.

For instance, in the renewable energy sector, rotary cable connectors in wind turbines ensure smooth power transmission from the moving turbine to the stationary grid. Likewise, in automation industries, these connectors contribute to operational efficiency by maintaining uninterrupted signal flow between rotating parts in various machinery.

Hence, understanding rotary cable connectors and their varied applications underscores their undeniable contribution to the efficient operation of complex systems throughout different industries. With the continuous advancement of technologies and requirements, the importance and role of these essential components are only set to increase.

Rotary Cable Connector Design and Functionality

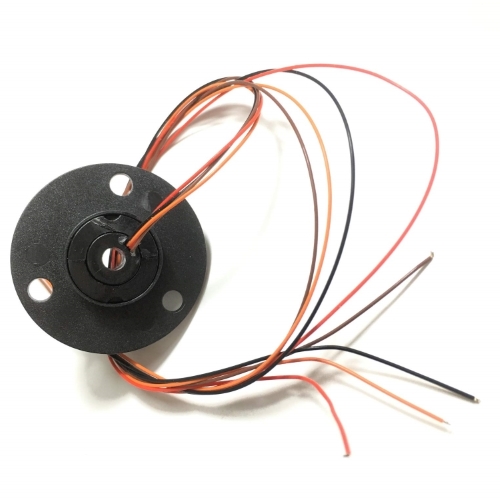

Rotary cable connectors are stunning examples of engineering, designed to simplify the complex task of transmitting power, signals, and data between stationary and rotating parts while withstanding a variety of operational and environmental conditions. Looking beneath its unassuming exterior reveals a world of intricate design and precise functionality.

At its core, a rotary cable connector consists of a stationary part, often referred to as the stator, and a rotating part known as the rotor. Both the stator and the rotor are designed with concentric rings or tracks. These tracks on the stator correspond with those on the rotor, creating multiple circuits that enable simultaneous transmissions.

The essential components also include a transmission medium, usually in the form of brushes or brushless capsules, that slides on the tracks, creating an electrical connection. It’s through this connection that power, signals, and data smoothly transit from the stationary to the rotating parts and vice versa, even while the system continuously rotates.

This ability to maintain a constant and consistent connection through rotation is what sets rotary cable connectors apart. They have evolved beyond just being a bridge, to becoming an active facilitator in the transmission process. They can handle various currents and voltages, rapidly transfer data, and reduce signal loss, which are critical for high-performance applications.

In some advanced configurations, rotary cable connectors are designed to handle a mix of power, signals, and data transmission concurrently. This hybrid approach allows them to contribute to the efficiency and effectiveness of complex systems ranging from industrial machinery to communication satellites and renewable energy installations.

In essence, the design and functionality of rotary cable connectors equate to unbroken, efficient transmission, which is central to their role in various applications. By mastering the basics of these components, you can better comprehend their ever-growing suite of applications across diverse industries.

Key Considerations for Choosing the Right Rotary Cable Connector

Selecting the appropriate rotary cable connector for a particular task or industry is not a simple pick-and-choose process. Various key considerations come into play to ensure the connector is not only efficient but also well-suited for a specific environment, thus promising durability and optimal performance. Here are a few critical factors to consider:

- Application Requirements: The first step in choosing a suitable connector involves having a clear understanding of the specific application and industry requirements. These can range from the need to handle high power loads in an industrial manufacturing plant to enabling high-speed data transfer in telecommunications infrastructure. Being able to match the connector’s specifications to these nuanced requirements of individual applications can ensure the selection of an effective and reliable connector.

- Environmental Factors: The conditions in which the connector will be operating are another chief concern. For instance, some rotary cable connectors might need to withstand high or low temperatures, survive a humid environment, resist dust ingress, or combat corrosive elements, such as those present in harsh industrial environments or outdoor installations. Therefore, it is essential to choose a connector designed to resist these environmental challenges and ensure durable performance.

- Electrical Requirements: Connectors need to meet specific electrical criteria as well, including voltage, current, and resistance capacities. For example, a high-voltage application would require a connector designed to handle high voltages without risking a breakdown or dangerous electrical faults. Such electrical requirements form the foundation for ensuring the safety and integrity of the entire setup.

- Signal and Data Transmission: In today’s digital age, the need for high-speed data transfer and minimum signal loss is becoming increasingly important. As such, understanding the connector’s capacity for signal integrity and data speed becomes a significant part of the selection process. Specific connectors might be better suited for applications where speed and reliability of data transmission are crucial.

- Mechanical Requirements: Lastly, the physical aspects of the connector, such as its size, weight, and mounting options, need to be assessed. These factors ensure that the connector can fit comfortably within the system’s constraints, without negatively impacting the structure or stability of the equipment.

In conclusion, selecting the appropriate rotary cable connector depends on a confluence of factors, each of which plays an instrumental role in ensuring the connector’s compatibility, functionality, and longevity within a specific application.

Popular Applications of Rotary Cable Connectors

Rotary cable connectors have become a cornerstone in not just a few, but many industries, owing to their versatility, durability, and efficiency in transmitting power, signal, and data between rotating and stationary components. Their functions extend across a wide spectrum of applications each with its unique operational requirements and challenges. Let’s explore how they play a crucial role in some of these predominant industries:

- Automation: The world of automation and robotics heavily relies on rotary cable connectors to keep machinery and robotic arms working seamlessly. They are used to facilitate smooth and efficient power and signal transmission in various automated systems. Whether it’s in an automated assembly line, robotic packing mechanisms, or even in advanced robotic surgical systems, rotary cable connectors render uninterrupted operations, thereby enhancing productivity and minimizing downtime.

- Renewable Energy: In the renewable energy industry, particularly wind energy, rotary cable connectors play a significant role in efficient power generation. They sit at the base of the towering wind turbines, enabling the transmission of generated electricity from the rotating turbine blades to the stationary grid system. By functioning in this critical role, they aid in the continuous generation and stable supply of renewable energy.

- Aerospace: Rotary cable connectors’ applications extend to the realms of aerospace as well. They’re used in satellites, communication equipment, radar systems, and much more. They enable the rotation of satellite dishes and radar equipment without losing signal integrity, essentially establishing robust and reliable communication systems in the vast expanse of space.

- Telecommunications: Rotary cable connectors also hold an important position in the telecommunications industry. They’re involved in synchronizing rotating antennas with stationary base stations. Ensuring reliable signal and data transmission is key in this area and rotary cable connectors excel at the task, making quick and efficient communication possible in diverse settings.

Whether it’s making industrial processes more efficient, enabling green energy technologies, supporting aerospace advancements, or facilitating seamless communication, rotary cable connectors are embedded deeply into various industries. Their unique ability to facilitate steady transmission between rotating and stationary components is irreplaceable, and their applications are only set to expand as technology advances.

Rotary Cable Connector Manufacturers and Suppliers

Given the vast range of applications for rotary cable connectors, numerous manufacturers and suppliers have emerged to cater to different industries and requirements. While many of these companies produce high-quality products, there are also noticeable distinctions in their offerings, support, and expertise. Let’s explore some of the leading names in the world of rotary cable connectors by comparing their portfolios, quality, and customer assistance.

| No. | Manufacturer | Website |

|---|---|---|

| 1 | Hangzhou Grand Technology | https://www.grandslipring.com/ |

| 2 | Moog Inc. | https://www.moog.com/ |

| 3 | Stemmann-Technik | https://www.stemmann.com/en/home |

| 4 | Schleifring | https://www.schleifring.com/ |

Hangzhou Grand Technology

Hangzhou Grand Technology Co., Ltd. started as a special slip ring manufacturer in 2011. Grown into slip rings, rotary joints, and slip ring assembly experts of today with 6,000 square meter manufacture complex.

Obtained ISO9001, Rosh, CE, and GJB9001B certificates a number of slip rings, rotary joint patents, and proud of our products can meet military grade. Collaborated with universities, institutes, and renowned factories across Asia and Europe including Panasonic, SIEMENS, CSIC, SAMSUNG, HUAWEI, etc.

Moog Inc.

Moog is a leading supplier of high-performance slip rings for various industries, including aerospace. Among their offerings, Moog’s SR Series Slip Rings are designed for the demanding environments of helicopters, excelling in performance, reliability, and customization potential.

Stemmann-Technik

Stemmann-Technik, a part of the Conductix-Wampfler Group, offers a broad range of slip rings, including solutions for helicopters. Their Livietta Slip Ring Assemblies are designed explicitly for harsh and demanding environments in the aviation sector, providing reliable signal and power transmission.

Schleifring

Schleifring is a well-known manufacturer of electromechanical systems, including slip rings customized for various industries. Their Aircraft Slip Rings cater specifically to helicopters, offering robust performance, low wear, and high reliability to meet the challenges of aviation applications.

If you want to know more about other slip ring manufacturers, you can read Top 10 Slip Ring Manufacturers in China, Top 10 Slip Ring Manufacturers In the USA Market 2023, and Top 10 Slip Ring Industry Key Manufacturers 2023.

While these are some of the leading manufacturers and suppliers of rotary cable connectors in the market, many other reputable players cater to specific industries or niche applications. In the process of comparing different providers, customers must look into factors such as product range, customization options, quality assurance, technical support, and customer service. Carefully weighing these elements should lead to the selection of a partner capable of delivering the most suitable and efficient rotary cable connectors for a given application or industry.

Rotary Cable Connector Installation, Maintenance, and Troubleshooting

The performance and durability of a rotary cable connector are contingent on its proper installation and periodic maintenance, as well as addressing any issues promptly and effectively. Let’s delve into the best practices for installation, maintenance, and troubleshooting to optimize their performance and longevity.

Installation

- Manual Review: Before commencing installation, always carefully read the manufacturer-provided manual. This will ensure a clear understanding of specific guidelines, safety precautions, and product specifications for the chosen connector.

- Environment Preparation: Ensure that the installation site is clean and free from dust, debris, or any other contaminants that could adversely affect the connector’s performance.

- Proper Alignment: During installation, ensure that the connectors are correctly aligned to avoid unnecessary stress on the cables or the connector’s internal components. Misaligned connectors can lead to premature wear or damage.

- Secure Mounting: Proper mounting of the connector and securing the cables is crucial to mitigate any strain resulting from movement or vibration. Use all the recommended mounting hardware as per the manufacturer’s guidelines and ensure it is firmly fastened.

- Testing: Finally, always perform a thorough test of the connection after installation to confirm that the integrity of the electrical, signal, and data transmissions is maintained.

Maintenance

- Regular Inspection: Conduct periodic visual inspections of the rotary cable connector to ensure any signs of wear, tear, or damage are quickly detected and addressed.

- Cleanliness: Keep the connectors and surrounding environment free of dust, debris, and moisture. This helps prevent any buildup that might impair the connector’s functionality and result in increased friction, heat, or wear.

- Lubrication: As per the manufacturer’s specifications, apply the appropriate lubricant to the rotary connector’s moving parts. Proper lubrication reduces friction, ensures smooth operation, and prolongs the connector’s life.

- Performance Monitoring: Constantly monitor the performance of the connector, observing any changes in signal strength, data transmission rates, or electrical characteristics. These changes can indicate potential issues that warrant further investigation and troubleshooting.

Troubleshooting

- Manufacturer’s Guidelines: Always refer to the manufacturer’s manual as the first line of troubleshooting, as it often contains specific instructions for addressing common issues based on the connector model and design.

- Diagnose Symptoms: Determine the likely cause of the problem by carefully examining any symptoms, such as intermittent connections or poor signal quality. This can help narrow down the potential issues and identify appropriate solutions.

- Physical Inspection: Inspect the connectors for any physical damage, loose connections, or other visible issues that could be contributing to the problem. Addressing these concerns can often resolve the issue or help diagnose the underlying cause.

- Test and Verify: After making any fixes, test the connector’s performance and verify that the issue has been resolved. If the problem persists, consider consulting the manufacturer’s technical support for further guidance.

In conclusion, proper installation, ongoing maintenance, and prompt troubleshooting are essential to ensure that rotary cable connectors provide optimal performance and long-lasting service. Adhering to these best practices and the manufacturer’s guidelines will result in connectors that can meet their intended functions and serve as reliable components in various applications.

Get Expert Advice on Rotating Joints. Submit Your Inquiry Today

Rotary Cable Connector Emerging Trends and Future Developments

As with many different technologies, the landscape for rotary cable connectors continues to evolve, driven by advancements in materials, designs, and related technologies. The convergence of these elements is paving the way for connectors that are more efficient, durable, and suitable for even more diverse applications. Here are some of the trends and developments expected to shape the future of rotary cable connectors:

- Advanced Materials: Manufacturers are increasingly experimenting with advanced materials to enhance the durability, conductivity, and overall performance of their rotary cable connectors. The incorporation of such materials paves the way for connectors that can withstand harsher conditions, endure increased levels of stress, and provide more reliable and efficient transmission. For example, advanced alloys, ceramics, or composite materials are finding their applications in connector parts to extend their lifespan and performance.

- Miniaturization: As technology trends lean toward miniaturization, rotary cable connectors follow suit. Manufacturers are innovating their designs to produce smaller, lighter connectors without sacrificing their capabilities. This trend is particularly relevant in domains like aerospace, defense, and robotics — where weight and size carry high importance.

- Increasing Data Rates: With the growing demand for high-speed data transmission, rotary cable connectors are being designed to handle greater data rates. Harnessing advances in materials and design, the connectors of the future will offer unparalleled speeds to meet the requirements of rapid data transfer, particularly in telecommunications and computing industries.

- Smart Features: In line with the Internet of Things (IoT), future rotary cable connectors might also include smart features, such as predictive maintenance, real-time performance monitoring, or self-diagnosis of issues. These innovations could substantially aid in simplifying and enhancing the efficiency of connector maintenance.

- Integration with Other Technologies: Another rising trend is the increasing integration of rotary cable connectors with other technologies, such as optoelectronic components or advanced sensors. This integration allows the rotary cable connectors to function in more complex, multifaceted systems, opening up new application areas.

The continuous advancements in components like rotary cable connectors demonstrate how innovation can incrementally enhance technology even in areas that might seem very specialized or obscure. By following these trends and keeping an eye on emerging developments, stakeholders in various industries can anticipate the future direction of such crucial elements and plan their strategies accordingly. As always, manufacturers will play a pivotal role in incubating these changes and incorporating them in a way that drives value for their customers and users.

Conclusion

Rotary cable connectors, though small, play an integral role across industries, making understanding them crucial. As these devices continue to evolve, they promise to match the demands of modern industry, meeting the needs of everything from emerging renewable energy technology to complex aerospace applications.

See What We Can Do