This comprehensive guide aims to shed light on the concept of rotating electrical couplings, unraveling their intricate operation, classifying their myriad types, detailing the factors influencing their selection, and proffering installation and maintenance tips. It further explores their evolving role across diverse industries and speculates on their future course.

Introduction to Rotating Electrical Couplings

In the realm of electrical engineering and advanced machinery, rotating electrical couplings serve as a critical nexus of power and data transmission. They are devices specially designed to transfer electrical power or signal from a stationary part (stator) to a rotating part (rotor), without hindering the rotational movement.

These versatile components are present in a wide plethora of devices we routinely encounter. For example, they facilitate power transmission in wind turbines where the blades rotate under the force of wind. Similarly, these couplings are an integral part of modern medical equipment like MRI machines, where they transmit electrical signals from the stationary body of the apparatus to the rotating gantry.

Drawing the crux of their functionality from their ability to ensure uninterrupted power or data flow while accommodating kinetic movement, rotating electrical couplings are much more than mere connectors. Their seamless integration within a wide array of systems and machinery spanning from the automotive industry and renewable energy operations to telecommunications and industrial automation underlines their significant role in supporting contemporary technology.

Acting as the backbone of rotating machinery, their absence could disrupt modern work layouts that heavily rely on the operation of rotating machines. They not only ensure the smooth operation of these machines but also reduce wear and tear, contributing to the durability and longevity of the equipment in which they are installed.

Thus, rotating electrical couplings are not just critical for the functioning of countless devices and systems, but their role in enhancing the efficiency and reliability of such technological applications is indeed indispensable. As we continue to forge ahead in an era marked by extensive automation and increasing demand for efficient power transmission methods, the role of rotating electrical couplings only appears to be amplifying.

Working Principle of Rotating Electrical Couplings

Understanding the working principle of rotating electrical couplings necessitates an exploration of the elegant harmony of physics and engineering that is at their core. The basic role of these components is to transmit electrical power or signals from a stationary to a rotating component, without physically connecting the two, hence allowing unimpeded rotational movement.

Basic Working Principle

The basic operation of a rotating electrical coupling is founded on the principles of electromagnetism. The key idea is to create an electromagnetic field that bridges the gap between the stationary and rotating components. When electric current passes through the stationary part, known as the stator, it results in a magnetic field. The magnetic field then induces an electric current within the rotating component or the rotor, thereby successfully transmitting energy across the moving interface.

Key Elements of a Rotating Electrical Coupling

A typical rotating electrical coupling comprises two primary components – a stator and a rotor. The stator is the stationary part, often connected to the power source or signal generator. The rotor, being the rotating part, is attached to the machinery component that requires the transfer of power or signal.

In addition, there are other elements like the housing that protect the coupling from external damage and magnetic cores that connect electric windings to initiate the magnetic field, enhancing the efficiency of power transmission.

Some advanced models also feature components like slip rings (for conduction) and brushes (for maintaining contact), especially when the power requirement is extensive or when the system requires the transmission of unique types of signals, for instance, in certain communication applications.

Mechanics of Energy Transfer Through Coupling Stages

The mechanics of energy transfer in a rotating electrical coupling begins with the passage of electricity through the stator winding, creating an electromagnetic field. The generated magnetic field then traverses the air gap separating the stator and rotor.

The rotor, located within this field, reacts to the magnetic field. In response, an electric current is induced within the rotor, thus following Faraday’s law of electromagnetic induction. The induced current then powers the moving part of the machine.

It is important to note that while the aforementioned process may seem simple, the actual mechanics might vary greatly based on other factors such as the type of coupling, installation process, operational environment, and specific application. Yet, the core idea of energy transfer remains the same, centering on the foundational principles of electromagnetism.

In sum, the working principle of rotating electrical couplings is a splendid demonstration of the harmonious amalgamation of various facets of physics and engineering, creatively designed to overcome the challenges of power and signal transmission in rotating machinery.

Types of Rotating Electrical Couplings

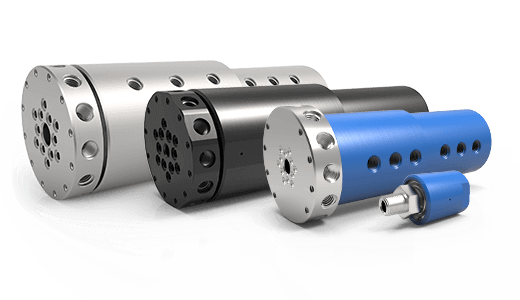

To cater to the diverse requirements posed by a wide range of industries and applications, rotating electrical couplings exhibit substantial variation in terms of design, materials, power transmission types, and specific applications. This section aims to provide insight into the primary classification and types of rotating electrical couplings.

Classification Based on Design and Materials

Single-Channel and Multi-Channel Couplings

These are designed to transmit power or signal through a single channel or multiple channels. Single-channel couplings are well-suited for simple applications, while the multi-channel variants find application in complex systems that require the transfer of multiple signals or power levels simultaneously.

Capacitive and Inductive Couplings

Capacitive couplings use capacitance principles to transmit energy between a stator and rotor through an insulating medium, ensuring low noise, no contact, and low wear. Inductive couplings, on the other hand, rely on electromagnetic induction, which is the primary operating mechanism for most rotating electrical couplings.

Material-Based Classification

The material used in a coupling can greatly influence its performance. Common materials include copper, aluminum, and various composites. Copper-based couplings excel in terms of electrical conductivity and are highly efficient, whereas aluminum offers a lightweight and corrosion-resistant option.

Classification Based on Power Transmission Types

Electrical Slip Rings

Electrical slip rings are rotating couplings designed to transmit power and electrical signals across rotating interfaces. They often find use in wind turbines, communication equipment, and radar systems.

Fluid Rotary Unions

Fluid rotary unions transfer liquid or gas media across rotating components. Their applications stretch across various industries, including oil and gas, food and beverage, and pharmaceutical sectors.

Hybrid Couplings

These couplings combine the traits of electrical and fluid couplings, allowing for the simultaneous transfer of electrical signals, power, and fluid media.

Classification Based on Specific Applications

Fiber Optic Rotary Joints

These couplings facilitate the transfer of optical signals across rotating interfaces. Examples include extremely high-speed data transmission in telecommunication systems and military applications.

High-Frequency Rotary Joints

High-frequency rotary joints transmit high-frequency signals, such as those found in radar and satellite systems. They are often customized to meet the demanding specifications and requirements of these systems.

Wind Turbine Slip Rings

Specially designed for wind energy applications, wind turbine slip rings transfer power and signals between the stationary nacelle and rotating hub of a wind turbine.

In summary, the types of rotating electrical couplings are manifold, and tailored to fit the specific demands imposed by various industries and applications. By categorizing these couplings based on factors like design, materials, and power transmission types, one can better comprehend the intricate nuances of these intricate devices.

Factors Influencing the Selection of Rotating Electrical Couplings

The selection of rotating electrical couplings for a specific application is an intricate process, governed by a multitude of factors. Given the critical role they play in ensuring the seamless operation of various machinery and equipment, the decision-making criteria extend beyond mere electrical specifications. Here, we delve into these key considerations and their overarching implications.

Durability and Reliability

One of the first parameters to be considered is the durability and reliability of the coupling. The coupling is expected to withstand long operational hours, potentially under significant mechanical stress and temperatures. Therefore, it is necessary to confirm the coupling’s capability to endure such conditions without compromising its performance. Moreover, high reliability is preferable as frequent replacements can cost time, disrupt operations, and induce financial burdens.

Power Handling Capabilities

The ability of a coupling to handle the power or signal loads related to its application is a crucial parameter. The operator must ensure that the coupling’s power handling capabilities align with the requirements of the application. Handling power beyond the coupling’s capacity might lead to overheating and early failure.

Environmental Resistance

Operating conditions vastly differ across industries. Some applications might expose the coupling to harsh environments, demanding higher environmental resistance. This includes resistance to factors like extreme temperatures, moisture, dust, or corrosive agents.

Size and Space Constraints

Space utilization is an important aspect of modern machinery design, resulting in a demand for compact, yet powerful couplings. In industries where space is a critical constraint, such as robotics or aerospace, smaller couplings that do not compromise on performance are favored.

Cost Considerations

Undoubtedly, cost plays a significant role in the selection of rotating electrical couplings. It is not just the upfront cost that counts, but also the long-term operational costs linked to maintenance and replacements. A holistic view of costs can lead to optimized decisions in terms of the total cost of ownership.

In summary, the selection of rotating electrical couplings is an exercise in balancing technical specifications, operating conditions, and financial considerations. By taking into account factors such as durability, power handling capabilities, environmental resistance, size, and cost, one can make a sound decision that ensures operational efficiency and long-term reliability.

Rotating Electrical Couplings Installation and Maintenance Tips

The performance of rotating electrical couplings significantly depends on how they are installed and maintained, therefore, understanding and respecting the recommended practices can directly contribute to their efficiency and longevity. This section provides a brief overview of the installation process, its importance, and some basic maintenance tips.

Overview and Importance of Proper Installation

Correct installation of rotating electrical couplings is crucial in ensuring their optimal operation and preventing premature failures. Misalignment and improper connections are common installation pitfalls that can negatively impact the performance of the component and even lead to its failure.

Instability in power transmission, overheating, or frequent need for replacements are usually the tell-tale signs of incorrect installation. Therefore, it’s crucial to follow manufacturer instructions or engage a professional to help with the initial setup of these vital components. This ensures that the coupling integrates seamlessly with the overall machine mechanism and delivers the desired performance levels.

Basic Maintenance Tips to Ensure Longevity

Even after proper installation, maintaining the rotating electrical couplings in their best working condition is vital in securing prolonged service life and dependable performance. Here are some basic maintenance tips:

- Regular Inspection: Regularly inspect the coupling for any signs of wear and tear or damage. Check for any irregularities in operation, such as unusual sounds or vibrations, as they might signify internal malfunctions.

- Cleaning: The coupling’s internal components and surfaces should be kept clean. Accumulation of debris can adversely affect the functioning and efficiency of the coupling.

- Temperature Monitoring: Continuously monitor the temperature of the coupling during operation. Overheating could signify overload or insufficient cooling, which may impact long-term performance and reliability.

- Lubrication: If the coupling design requires it, proper lubrication should be ensured. Certain couplings need regular lubrication for efficient operation and to reduce friction between moving parts.

- Periodic Replacements: If after inspection, any part of the coupling is found to be worn out or not working as expected, replace it promptly to avoid cascading failures or reduced efficiency.

In conclusion, the proper installation and diligent maintenance of rotating electrical couplings are closely linked to their performance and longevity. By respecting the recommended practices, one can benefit from not only uninterrupted operations but also reduced costs associated with emergency repairs or unexpected failures.

Innovations and Trends in Rotating Electrical Coupling Technology

With rapid advancements in technology and an unrelenting demand for efficiency, reliability, and scalability, the sphere of rotating electrical coupling technology is experiencing a wave of innovation. These developments not only enhance the capabilities of existing models but also furnish users with new avenues for applications. This section explores some of these trends and their ramifications.

Latest Developments and Their Enhancements

Miniaturization

A key trend is the miniaturization of rotating electrical couplings, powered by advancements in materials and design. Compact and lightweight couplings without sacrificing performance enlarge their applicability in areas like robotics and portable devices.

Integration of Advanced Materials

The use of advanced materials such as high-performance alloys, Superconducting Magnetic Energy Storage (SMES) materials, and carbon-based materials enhance various aspects of the couplings like conductivity, durability, and resistance to adverse conditions.

Use of Digital Technology

Integration of IoT and AI into rotating electrical couplings allows real-time monitoring of their operation, facilitating predictive maintenance and improving reliability. This digital transformation also enables the coupling to adjust its parameters dynamically based on the operational conditions, enhancing energy efficiency.

Wireless Power Transmission

Emerging wireless power transmission technologies are pushing the boundaries of traditional rotating electrical couplings. The elimination of physical connectivity between the stator and rotor reduces wear and tear, in turn increasing the lifespan of the device.

Benefits of These Advancements for Users

These technological advancements bring about multiple benefits for the users:

- Improved Efficiency: By integrating smart controls and advanced materials, the efficiency of power transfer has improved substantially, leading to reduced energy consumption.

- Longer Lifespan: The use of advanced materials and the advent of wireless power transmission result in less wear and tear, thus extending the lifespan of the couplings.

- Ease of Maintenance: The integration of IoT allows for real-time monitoring and predictive maintenance, minimizing unexpected failures and promoting easier management.

- Compactness and Portability: Miniaturized couplings can be deployed in limited spaces, thus increasing their versatility of use in various applications.

In conclusion, the innovations in rotating electrical coupling technology are reshaping the way these devices function and their applicability. By embracing these changes, users can benefit from improved efficiency, longer lifespan, ease of maintenance, and enhanced adaptability.

Case Studies: The Role of Rotating Electrical Couplings in Different Industries

Rotating electrical couplings have found their way into a wide range of industries, given their ability to ensure the dependable and efficient transfer of power and signals across rotating interfaces. This section presents case studies from different sectors to showcase the versatility and the integral role these couplings play in these domains.

Case Study 1: Wind Energy Sector

Industry: Renewable Energy, Wind Turbines

Rotating Coupling Type: Wind Turbine Slip Rings

Application: Wind turbine slip rings bridge the gap between the stationary nacelle and the rotating hub, allowing the transfer of power and signals to optimize the orientation of the turbine blades concerning the wind direction.

Implications: By enabling real-time communication and data acquisition, these couplings provide valuable input to the control systems, thus ensuring efficient energy harvesting. Furthermore, they contribute to the minimization of mechanical stress on the components, reducing maintenance costs and downtime.

Case Study 2: Aerospace Industry

Industry: Aerospace, Satellite communication

Rotating Coupling Type: High-Frequency Rotary Joints

Application: High-frequency rotary joints facilitate the transfer of high-frequency signals between stationary and rotating parts in radar and satellite communication systems, ensuring uninterrupted data transmission.

Implications: These rotatory couplings have been pivotal in enhancing the precision, accuracy, and reliability of aerospace communication systems – indispensable features for defense and navigation applications.

Case Study 3: Robotics Industry

Industry: Manufacturing, Industrial Automation

Rotating Coupling Type: Miniaturized Multi-Channel Couplings

Application: Compact multi-channel couplings cater to the robotic arms’ needs in assembly lines, synchronizing multiple tasks like power transmission, data transmission, and fluid transfer.

Implications: These couplings have played a vital role in streamlining the production process, thereby increasing efficiency and cost-effectiveness. Moreover, they contribute to a reduction in the downtime associated with maintenance, fostering seamless, and continuous operations.

Case Study 4: Television Broadcasting Industry

Industry: Broadcasting, Television Broadcasting

Rotating Coupling Type: Fiber Optic Rotary Joints

Application: Fiber optic rotary joints are employed in satellite trucks to facilitate high-speed data transmission in the broadcasting industry. They allow the seamless transmission of high-definition video signals between the rotating antenna and the stationary equipment.

Implications: The implementation of these couplings has bolstered the quality and reliability of live news broadcasts and event coverage, facilitating instantaneous, crystal-clear communication.

The aforementioned case studies underscore the pivotal role rotating electrical couplings play across diverse industries. By enhancing the reliability and efficiency of their applications, these devices contribute to not only the advancement of technology but also our everyday lives.

Future Outlook of Rotating Electrical Couplings

The future of rotating electrical couplings is bright, spurred by the constant innovation and development in the field of electrical and mechanical engineering. As we move toward a more connected and technologically advanced society, these seemingly inconspicuous components will continue to play a pivotal role. This section delineates plausible trajectories for the development of rotating electrical couplings, based on current trends and research.

Speculations Based on Existing Trends and Research

With the advent of Industry 4.0, there is an increasing emphasis on the integration of smart technologies like IoT and AI into all aspects of manufacturing and production, rotating electrical couplings being no exception. Future couplings might come embedded with smart sensors and diagnostics, providing real-time data on operational efficiency and predictive maintenance alerts.

Further advancements in materials science could lead to the production of couplings with even higher durability, thermal resilience, and electrical conductivity. The development and integration of such high-performance materials may result in rotating electrical couplings that can withstand more extreme conditions and offer longer operational lifespans.

Innovation in wireless power transmission technology is another promising area. Current wireless power technologies have limitations regarding their range and efficiency. However, ongoing research in this area might bring us closer to a future where rotating electrical couplings can transmit power efficiently over greater distances without physical contact.

Potential Future Applications and Evolving Capabilities

As rotating electrical couplings become smaller, smarter, and more efficient, their potential applications could extend beyond traditional domains. They might become integral components of advanced medical implants, playing a crucial role in wireless power transfer for bio-electronic devices.

In the field of transportation, especially electric vehicles (EVs), rotating electrical couplings could facilitate the development of dynamic wireless charging systems, where vehicles are charged as they drive over embedded power sources.

Environmental energy harvesting, especially wind and ocean wave energy, could significantly benefit from advancements in rotating electrical coupling technology, which can improve the efficiency of energy capture and conversion, driving the green energy revolution forward.

The future of rotating electrical couplings holds immense promise. As they continue to evolve in line with emerging technological trends, their capabilities and applications are poised to expand. Whether it’s in smart factories, medical implants, or renewable energy systems, rotating electrical couplings will remain an indispensable component, silently but consistently powering our technologically advanced society.

Conclusion

While often operating silently in the background, rotating electrical couplings are integral to many technology weaves. As these components continue to evolve, they promise to inspire new frontiers of technological innovation.