In a world driven by automation, robotics, and intricate engineering, understanding the components operating behind the scenes is paramount. Slip ring units, often hidden in the shadows of more prominent technologies, play an indispensable role in numerous applications. As such, we have embarked on the mission to craft this comprehensive guide on slip ring units and unravel their significance.

This guide navigates the complexities of slip ring units, serving as a one-stop resource for anyone seeking a comprehensive understanding of their design, uses, and maintenance. The contents herein will also highlight the author’s expertise and address common questions, ensuring the coherence and relevance of the information presented. Whether you’re an industry expert seeking to deepen your knowledge or a newcomer looking to learn the ropes, this guide is tailored to meet your needs.

Overview of Slip Ring Units

Slip ring units, otherwise known as rotary electrical connectors, are vital components that facilitate the transmission of power and data signals across rotating and stationary joints. Their primary function is to enable the uninterrupted flow of electricity and information while preserving the mechanical integrity of the interface between stationary and moving parts.

In essence, they bridge the gap between rotational systems, allowing energy and data to pass through seamlessly despite the continuous motion of the machinery. This pivotal role is translated across a wide variety of industries and applications, contributing to increased efficiency and expanding the capabilities of modern technologies. Slip ring units are found in industries like wind turbine generation, aerospace, defense, robotics, and medical imaging, to name just a few.

An abundance of slip ring types accommodates the diverse demands of these industries. Various elements—such as size, design, and functionality—differentiate them. Some examples of slip ring types include:

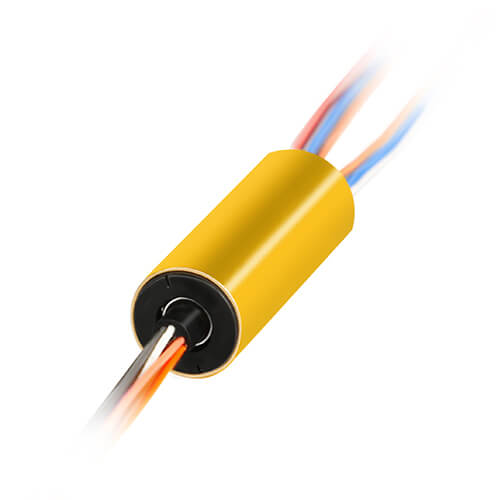

Capsule Slip Rings

Compact in design, they are ideal for systems where space is limited. Their small size, however, does not compromise performance, as they can handle both power and signal transmission effectively.

Pancake Slip Rings

As the name suggests, these slip rings boast a flat and low-profile design. They cater to applications where axial space is constrained, and functionality must be maintained within a confined area.

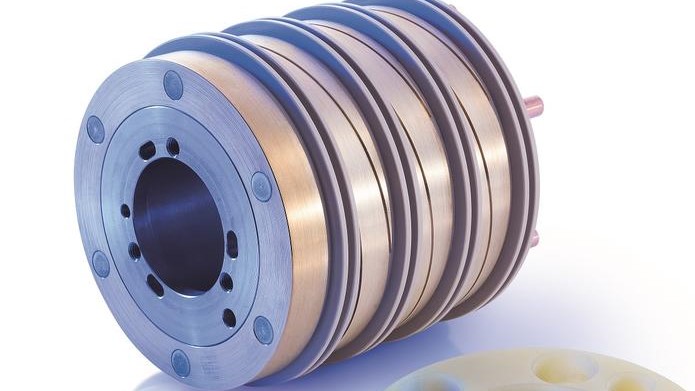

Through-bore Slip Rings

These slip rings feature a central hole or “bore” for the accommodation of other components such as shafts or cables. This design caters to applications wherein components must pass through the center of the slip ring unit.

In this guide’s context, establishing a fundamental understanding of slip ring units and their various types is crucial. It provides a solid foundation upon which the rest of the guide builds, laying the groundwork for a coherent and comprehensive look into the world of slip ring units.

Design and Structure of Slip Ring Units

In order to appreciate the intricacies of slip ring units’ design and structure, it is essential to dissect the components that collectively form their integrity. The primary components include brushes, conductive rings, housing, and, in some cases, additional elements such as bearings:

- Brushes: Typically made from metal or graphite, brushes maintain physical contact with conductive rings, ensuring the transfer of electrical signals and power between stationary and rotating parts.

- Conductive rings: Manufactured from metals with high conductivity, these rings create a circuit as they rotate. Brushes glide along the rings’ surface, allowing for a continuous flow of electricity and data.

- Housing: This protective enclosure contains the slip ring unit’s components, providing mechanical support and safeguarding the entire assembly from external environmental factors.

- Bearings (when applicable): These are used to support the rotating part of the slip ring unit and facilitate a smooth rotation by reducing friction and wear.

Following the examination of these essential components, we can better understand the design variations such as capsules, pancakes, and through-bore slip rings. Their distinctive design styles are shaped by the specific requirements of each application, and factors like size, shape, and center passage allowances play a significant role in aligning the right slip ring to the appropriate context.

Designing a slip ring unit requires extensive knowledge, technical skill, and precision. Striking a balance between performance, durability, and compatibility with specific applications is fundamental in creating a successful slip ring unit. The author’s expertise in industry plays a vital role in identifying and addressing the challenges that may arise during the design and manufacturing stages. This experience ensures that users receive slip rings tailored to their particular needs—an invaluable asset in a domain that relies heavily on customization.

By delving deeper into the design and structure of slip ring units within the guide, readers will gain an appreciation for the level of detail and expertise needed to create these essential components. Furthermore, it reinforces the coherence of the guide by establishing a sense of continuity in the exploration of slip ring units and their wide range of applications.

Selection Criteria for Slip Ring Units

The selection of the right slip ring unit is paramount to the seamless operation of various applications. However, making such a choice is not always straightforward. It necessitates careful consideration of several factors:

- Intended Usage: Before the selection process begins, understand the application where the slip ring unit will be implemented. Questions such as Will it be stationary or rotating? What kind of data or power needs to be transmitted? Must be answered to ensure the chosen unit meets the requirements.

- Environmental Factors: The environmental conditions under which the slip ring unit operates significantly impact its design and materials. For instance, a slip ring meant for a clean, indoor environment will greatly differ from one intended for harsh, outdoor conditions.

- Load Capacities: Obviously, power and data transmission rates are critical selection criteria. The load capacity of a slip ring determines its ability to handle power loads and signal transmission rates as required by the application.

Professional guidance can be invaluable in aiding the selection process. Given the myriad options available and the diversity of applications, an industry professional’s advice can highlight the most compatible slip ring for specific needs. Their understanding of various factors and practical experience with diverse units make them the ideal guide to facilitate well-informed decision-making.

As this guide delves deeper into the laws governing slip ring units, the section on the selection criteria provides an essential toolset to decipher the complexities of choosing the right unit. This forms a coherent transition from understanding the structure and design of slip ring units to the practical skills needed to select and utilize them effectively. It ensures that readers can implement what they learn from this guide in real-world scenarios, thereby underlining the guide’s core aim of empowerment.

Slip Ring Units Installation and Integration

Installing a slip ring unit correctly is crucial to harness its full potential and ensure optimal performance. The installation process must take into account factors such as the type of slip ring, its mounting options, and space constraints among others.

Given the dynamic nature of these units, accurate alignment is critical. The connection between the brushes and the ring should be precisely aligned to ensure the effective transmission of signals or power. A misalignment may lead to functional failures, increased wear, and diminishing performance over time.

Besides alignment, secure connections are key to a successful installation. Proper tightening of screws and checking the solidity of electrical connections can prevent possible disconnections during operation, which could lead to machine downtime or loss of data.

When it comes to integrating slip ring units into different systems, it is essential to consider the specific requirements of each application. For instance, in high-speed applications, the slip ring units should feature low electrical noise. Similarly, in systems exposed to harsh environments, choosing slip rings made from sturdy, corrosion-resistant materials is advisable.

Sharing these best practices and others pertinent to slip ring installation and integration are crucial elements this guide offers. Drawing upon the author’s extensive experience and expertise, readers are equipped with practical insights, allowing them to make informed decisions and ensure the successful implementation of slip ring units.

This section aligns perfectly with the previous parts of the guide, transitioning from the selection of slip ring units to their installation and integration. The coherence and continuity maintain an engaging and logical flow of information. It reiterates the guide’s commitment to providing readers with comprehensive knowledge about slip ring units—from understanding their design to practical application.

Slip Ring Units Maintenance and Troubleshooting

Maintaining slip ring units in optimal condition is crucial, not only for their performance but also for the long-term success of the applications they serve. Exceptional maintenance begins with routine checks to assess the condition of the brushes, rings, and connections. Keeping these elements clean and free from dust or other contaminants will ensure a smooth transmission of power and data.

Over time, the wear and tear on slip rings can cause a myriad of issues, such as inconsistent signal transmission or loss of power. In many cases, these issues originate from simple conditions like dirty brushes or loose connections. Regular maintenance can identify these problems early, allowing for quick resolutions and a prolonged lifespan of the unit.

Despite diligent maintenance, some troubleshooting scenarios might arise that are too complex for even the most dedicated caretakers. In these instances, professional assistance becomes critical. Experts, with their deep understanding of slip ring units, can pinpoint and mitigate problems beyond the reach of standard checks and maintenance.

Exploring maintenance and troubleshooting in this guide brings forth vital insights into the daily handling and care of slip ring units. By understanding how to maintain and troubleshoot these units, readers will maximize the performance and lifespan of their slip ring units, contributing to their application’s overall efficiency and lifespan.

This section complements the previous sections by not only providing insights into the installation and integration of slip ring units but also exploring ways to maintain and troubleshoot them. It reinforces the guide’s coherence by taking a linear approach to explaining slip ring units—from design to installation and finally, to maintenance and troubleshooting.

Slip Ring Units Industry and Application Examples

Slip ring units are vital components in countless applications across diverse industries. Demonstrating their versatility and importance, real-world examples provide a lens through which readers can appreciate the various ways in which slip ring units adapt and contribute to successful operations.

Wind Energy

Slip rings are widely used in wind turbine generators to transmit power and data from the rotating blades to stationary components, illustrating their importance in the renewable energy sector.

Medical

Slip ring units enable critical functions in Medical such as CT scanners, allowing the rotating gantry to transmit diagnostic data to the stationary control system.

Aerospace and Defense

In radar systems, slip rings facilitate continuous 360-degree rotation, enabling the transmission of power and data between stationary and rotating components for reliable communication and monitoring.

Automation and Robotics

Slip rings uphold the seamless operation of robotic arms and automation equipment, ensuring unimpeded transmission of data and power during complex rotation movements.

Drawing from the author’s extensive experience in designing and manufacturing slip rings, this section highlights the impact of these units across various applications, as well as insights into innovation and customization tailored to different industries.

Furthermore, the guide will discuss potential future advancements in slip ring technology, such as the possible integration of contactless solutions like wireless power and data transmission, which could shape or impact the usage of traditional slip rings. This exploration of rising technologies underscores the guide’s commitment to staying at the forefront of innovation and supplying readers with well-rounded and forward-looking information.

By sharing real-world examples and discussing future developments, the guide builds upon the foundational principles and practical applications discussed in previous sections, enriching the readers’ understanding of slip ring units. This approach maintains the guide’s coherence, cementing the invaluable nature of slip ring units across industries and amplifying the importance of understanding their design, application, and maintenance.

Conclusion

With this guide, we aimed to convey the nuances of slip ring units, underlining the role they play in various sectors. As an industry professional, any further inquiry or need for consultation is invited. After all, a well-informed decision is often the crux of seamless, uninterrupted operations.

FAQs about Slip Ring Units

Below, the author leverages her industry expertise to address some of the most commonly asked questions regarding slip ring units:

Q1: What is the purpose of slip ring units?

A: The primary purpose of slip ring units is facilitating the transmission of power and data between stationary and rotating parts in many applications, ensuring smooth and efficient operation.

Q2: How do I determine the right slip ring for my application?

A: The choice of a slip ring largely depends on several factors including the intended usage, the environmental conditions where the device will be operated, and the load capacities for power and signal transmission. It’s recommended to seek advice from industry professionals to guide you in selecting the right slip ring unit.

Q3: How do I install and maintain a slip ring unit?

A: Installation procedure varies depending on the type of slip ring, but it typically involves ensuring accurate alignment and secure connections. As for maintenance, regular checks on the condition of brushes, contacts, and connections are vital in keeping the unit in optimal condition.

Fill out the form to get in touch with us regarding slip rings. We’ll provide you with all the necessary information and pricing.