In this article, we delve deep into the workings of squirrel cage motors, unpacking everything from their basic construction and principles of operation to their vast applications and the future that awaits them. Designed for professionals and enthusiasts alike, this guide provides a thorough understanding necessary to appreciate and handle these motors effectively.

Introduction to Squirrel Cage Motors

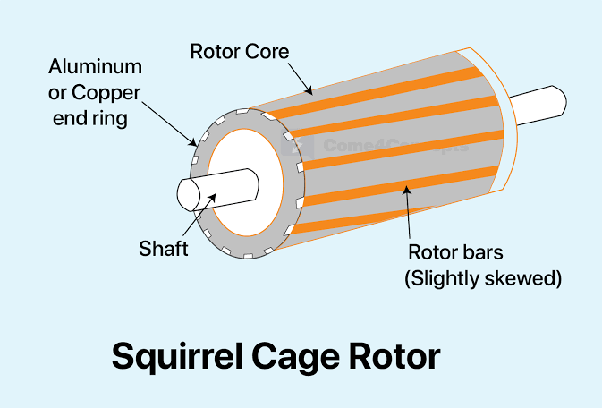

Squirrel cage motors, named for their unique rotor design resembling a squirrel or hamster wheel, are a type of induction motor pivotal to modern engineering and technology. This motor features a simple yet robust structure where the rotor, constructed of conductive bars connected at both ends by rings, effectively forms a cage. When alternating current (AC) flows through the stator, it generates a rotating magnetic field that induces an electric current in the rotor bars. This interaction between the stator’s magnetic field and the induced current in the rotor produces a torque that causes the rotor to spin, transforming electrical energy into mechanical motion without the need for physical contact between stationary and moving parts.

Their innovative design confers numerous advantages, including durability, low maintenance, and high efficiency, positioning squirrel cage motors as an invaluable component across a myriad spectrum of applications. In the realms of industry, these motors are the workhorses behind the scenes, powering machinery such as pumps, conveyors, and fans. They are integral to manufacturing processes, where reliability and efficiency are paramount. Beyond industrial environments, their significance extends into commercial and residential territories, driving HVAC systems, household appliances, and even transitioning toward automotive and renewable energy applications. The ubiquity of squirrel cage motors in these sectors underscores their critical role in not only keeping our industries running smoothly but also in enhancing our day-to-day lives through their silent operation in countless devices and systems.

Their universal application is a testament to the adaptability and enduring nature of squirrel cage motors, making them a cornerstone of modern electrical engineering and a key driver of innovation and efficiency across various industries.

The Basics of Squirrel Cage Motors

Definition and Design

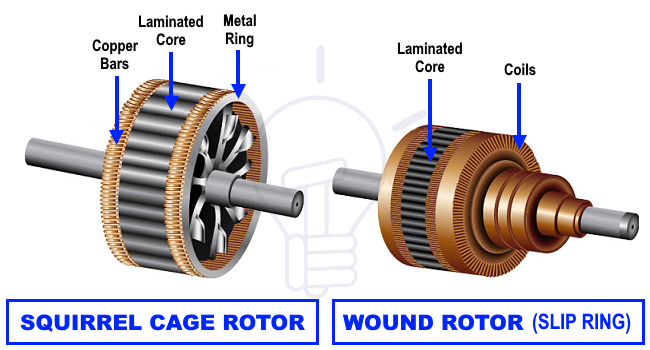

At its core, a squirrel cage motor is an induction motor distinguished by its simplistic yet efficient design. Central to this design are two main components: the rotor and the stator. The stator forms the stationary part of the motor, consisting of coils of wire that are connected to the electrical supply. The rotor, which is housed inside the stator, is the rotating part and is where the squirrel cage motor derives its name. It comprises a series of conductive bars that are parallel to the motor’s shaft and connected at both ends by metal rings, creating a cage-like structure reminiscent of a wheel or treadmill designed for a pet squirrel, hence the name.

This design is not accidental but borne out of a necessity for durability, efficiency, and cost-effectiveness. Unlike other electric motors that may use brushes and commutators to transfer electricity to moving parts, the squirrel cage motor’s rotor receives its electrical currents indirectly through electromagnetic induction, allowing for a more straightforward construction that reduces wear and tear and maintenance needs.

Operating Principle

The operating principle of squirrel cage motors hinges on the phenomenon of electromagnetic induction, wherein an electric current produces a magnetic field and, conversely, a magnetic field induces an electric current in a conductor. When the motor’s stator is connected to an AC power supply, it generates a rotating magnetic field. This magnetic field cuts across the conductive bars of the rotor, inducing an electric current in them. According to Lenz’s Law, the direction of the induced current is such that it opposes the change that produced it. In this context, the induced currents in the rotor bars produce their magnetic fields, which interact with the original rotating magnetic field of the stator.

The interaction between these magnetic fields creates a force on the rotor bars that propels the rotor to rotate in the direction of the stator’s rotating magnetic field. Essentially, the rotor attempts to “catch up” with the rotating magnetic field but, under normal operating conditions, never actually does, due to electrical and mechanical losses. This continuous chasing results in the constant rotation of the rotor and thereby produces the mechanical power for which the motor is designed.

The beauty of this design lies in its simplicity and effectiveness. Without the need for brushes or direct electrical contact between moving parts, squirrel cage motors achieve a level of durability and efficiency that makes them indispensable in applications where reliability and low maintenance are critical. Understanding these fundamentals—the elegant design and the principles of electromagnetic induction at work—is key to appreciating the widespread use and reliability of squirrel cage motors across countless industrial and domestic applications.

Types of Squirrel Cage Motors

Single Phase vs. Three Phase

Within the realm of squirrel cage motors, there are two main categories: single-phase and three-phase motors, each suited to different kinds of applications.

Single-phase motors, powered by single-phase AC power, are commonly used for lighter loads and in residential or small commercial settings. They are often found in household appliances like washing machines, refrigerators, and small water pumps. Their relatively simple design and operation make them cost-effective for such lower power demands. However, they may require additional components, such as capacitors, to start and run efficiently, and they are less efficient and powerful compared to their three-phase counterparts.

Three-phase motors, on the other hand, are designed to operate on three-phase AC power, which provides a balanced power supply and enables smoother, more efficient operation. This facilitates higher power output, making these motors more suited to industrial applications where high power and efficiency are essential. Three-phase motors are commonly found driving machinery such as industrial fans, pumps, and compressors. They are also known for their smoother operation with fewer vibrations, which can extend the life span of connected machinery and equipment.

Variations in Rotor Construction

The rotor construction in a squirrel cage motor significantly affects its performance characteristics, especially the starting torque and speed control. The two common types of rotor construction include the ‘deep bar’ design and the ‘double cage’ design.

In a deep bar rotor, the conducting bars are given a deep, narrow construction. At the start, the high resistance at the bar ends results in a substantial starting torque. As the motor increases in speed, the majority of the current progressively flows through the lower resistance path provided by the wider part of the bars. This shift from a high to low resistance helps maintain efficiency across varying loads and speeds.

The double cage design aims to improve on this and is constructed with two layers of rotor bars. Each layer or “cage” is designed with different properties—one set for high resistance and low reactance (upper cage), and the other set for low resistance and high reactance (lower cage). At start-up, the upper cage contributes to a high starting torque, and as the motor reaches normal operating speed, the current shifts primarily to the lower cage, favoring efficient operation at a nearly constant speed.

These structural variations provide engineers with the flexibility to choose a rotor design most suitable for a specific application, highlighting once more the adaptability and versatility of squirrel cage motors. Understanding the intricacies of these variations is vital to optimizing the efficiency and performance of these motors across a wide range of industrial and commercial uses.

Key Advantages of Squirrel Cage Motors

Durability and Reliability

Squirrel cage motors are famed for their durability and reliability, attributes that make them the preferred choice in continuous-use applications. Constructed with fewer moving parts and without the need for brushes or commutators, these motors are less susceptible to mechanical failure. The absence of contacts to transmit power to the rotor means that there is no electrical wear to contend with, negating a common failure point seen in other types of motors.

Furthermore, the very design of the squirrel cage rotor, with its robust bars and end rings, is inherently strong and can endure considerable stress without deformation. This solid construction is particularly suited to the rigors of industrial environments, where it’s not uncommon for motors to be in service for extended periods, often under heavy load conditions. Able to withstand harsh conditions such as temperature fluctuations, dust, and moisture, squirrel cage motors maintain their performance over time, which translates to fewer breakdowns and less downtime.

Maintenance and Cost-effectiveness

The simplification in design not only enhances the durability of squirrel cage motors but also leads to reduced maintenance requirements. The reliability of induction motors generally implies that they can run for long periods without the need for inspection or repair, saving on maintenance costs. These savings are compounded by the fact that the motors are energy efficient, consuming less power to do the same work as less efficient motors, thereby reducing operating costs.

Cost-effectiveness is also seen in the motor’s lifespan—their inherent ruggedness and ability to operate for millions of cycles with minimal attention mean that replacement frequencies are lower. When factoring in the initial purchase price with the savings from minimal maintenance and lower power consumption, the total cost of ownership of squirrel cage motors often outperforms that of many alternative motor types over the long term.

Efficiency and Performance

Energy efficiency and consistent performance are standout attributes of squirrel cage motors, thanks to their design and operating principle. These motors achieve high-efficiency levels as they harness electromagnetic induction to avoid physical contact between stationary and rotating parts, minimizing energy losses due to friction.

The performance of squirrel cage motors is also highly stable. They can maintain a consistent speed under variable load conditions, which is critical in applications that demand uniform operation, such as conveyor systems or fans. This stability is not only beneficial for end-use applications but, combined with high energy efficiency, it provides a positive impact on the overall energy footprint of industries that utilize these motors extensively.

In the context of increasing energy consciousness and sustainability goals, the energy efficiency and performance stability of squirrel cage motors offer a future-proof advantage that aligns well with the aspirations of modern industry. Their capability to deliver enduring, reliable, and cost-effective operation cements their position as a cornerstone in electrical engineering and automation.

Applications of Squirrel Cage Motors

Industrial Applications

In the industrial ecosystem, the simplicity and robustness of squirrel cage motors allow them to be the heartbeat of various systems. On conveyor belts, these motors are tasked with providing the necessary torque and speed to transport heavy loads across manufacturing and distribution facilities consistently and reliably. The ability of squirrel cage motors to start under load is particularly advantageous for conveyors that may need to begin operation with a significant burden already present.

Pumps, which are ubiquitous in industrial processes, rely on the ability of these motors to operate continuously, often in challenging environments, to circulate fluids, ranging from water to more viscous materials. The efficiency and reliability of squirrel cage motors ensure that such essential components of the industrial workflow maintain uninterrupted operation, contributing to the ongoing productivity and efficiency of industrial plants.

Fans and blowers also take advantage of the stable speed characteristics of squirrel cage motors, whether it’s providing forced ventilation for cooling electronic components, aerating water in treatment plants, or in the myriad of other applications where gas flow needs to be continuous and dependable. Squirrel cage motors’ endurance under constant use and ambient environmental conditions makes them indispensable in these roles.

Commercial and Residential Uses

Within the commercial and residential sectors, squirrel cage motors are often the driving force behind heating, ventilation, and air conditioning (HVAC) systems. Here, efficiency and quiet operation are of high value, as these systems are required to run for long hours, providing comfortable environments in locations ranging from large commercial buildings to individual residences.

Meanwhile, in household appliances, such as washing machines and dryers, these motors deliver the requisite performance without excessive noise, a key consideration for consumer satisfaction. Refrigerators and dishwashers also depend on the durability and efficiency of squirrel cage motors for their cooling and washing operations, highlighting the motor’s prominence in daily life.

Specialized Fields

Squirrel cage induction motors are advancing in specialized fields as well. In the realm of electric cars, innovation has led to the usage of these motors for propulsion due to their reliability and the advantageous nature of their operation at various speeds. Moreover, these motors can be cooled and controlled to provide optimal performance under a wide range of driving conditions, contributing to the viability and popularity of electric vehicles (EVs).

The automation industry is another area where the role of squirrel cage motors cannot be overstated. In automated machinery and robotic systems, the precise control and dependable operation of these motors are crucial. The inherent qualities of squirrel cage motors align well with the need for repetitive, accurate motion control, and their unfailing reliability is a desirable attribute in systems where uptime is critical.

The diverse applications of squirrel cage motors underscore their flexibility and adaptability. From the heavy-duty demands of industrial apparatus to the delicate precision required in personal electronics and the innovation-driven world of electric vehicles and automation, these motors have proven to be versatile and integral components driving modern technology forward.

Squirrel Cage Motor Installation and Maintenance Tips

Ensuring the efficient and reliable operation of squirrel cage motors begins with proper installation and is sustained by diligent maintenance practices. Here, we delve into the preliminary steps and ongoing care essential for maximizing the performance and lifespan of these motors.

Installation Best Practices

The foundation of a squirrel cage motor’s performance rests heavily on its installation process. Given the diversity of applications and environments in which these motors operate, adhering to a set of best practices during installation is paramount.

- Environmental Considerations: Before installation, evaluate the environment. High humidity, extreme temperatures, and dusty or corrosive atmospheres can necessitate specific motor designs or additional protective measures. Ensure that the motor selection is suitable for the intended environment.

- Alignment and Mounting: Precise alignment is critical to minimize vibration, which can lead to wear and tear on bearings and other components. Use calibrated tools to ensure the motor is perfectly aligned with the driven equipment. Furthermore, proper mounting on a stable, vibration-dampening base will enhance performance and longevity.

- Electrical Connections and Protection: Verify that the electrical supply matches the motor’s requirements. Incorrect voltage or frequency can lead to inefficient operation or damage. Protective devices such as fuses or circuit breakers should be in place to prevent overloading. Grounding the motor properly is also crucial for safety and performance.

- Ventilation: Squirrel cage motors rely on adequate cooling to prevent overheating. Ensure there is sufficient space around the motor for air circulation or proper connection to any external cooling systems if applicable.

- Commissioning: Before full-scale operation, conduct a test run to ensure the motor operates smoothly and that there are no unusual noises or vibrations. Checking the initial current draw, voltage at the motor terminals, and motor speed can help verify that the motor is operating within its expected parameters.

Routine Maintenance

While squirrel cage motors are lauded for their low maintenance needs, regular inspections and maintenance are vital to spotting and addressing potential issues before they lead to failures.

- Visual Inspections: Periodically inspect the motor for signs of wear, overheating, or contamination by dust and debris. Check for secure mounting and any corrosion on exposed surfaces.

- Cleaning: Keeping the motor and its surrounding area clean is fundamental. Accumulation of dust and debris can obstruct cooling vents and lead to overheating. Use soft brushes or compressed air approved for electrical equipment to clean the motor.

- Lubrication: Though many squirrel cage motors come with sealed bearings requiring no regular lubrication, those that do require it should be serviced as per the manufacturer’s guidelines. Over-lubrication can be just as harmful as insufficient lubrication.

- Electrical Testing: Regular electrical tests can help detect issues like insulation breakdown or imbalanced currents. Such tests should be conducted according to the guidelines provided by the motor manufacturer or industry standards.

- Vibration and Noise Monitoring: Persistent vibration or unusual noises can be early indicators of misalignment, bearing wear, or other mechanical faults. Implementing a routine schedule for monitoring can help catch these issues early.

By adhering to these installation best practices and maintaining a consistent routine for inspections and maintenance, the operational life of squirrel cage motors can be significantly extended. This not only ensures the reliability of the motors themselves but also the continuous, efficient operation of the systems they drive, thereby safeguarding productivity and minimizing downtime.

Squirrel Cage Motor Common Concerns and Troubleshooting

Despite their robust construction and reliable operation, squirrel cage motors can occasionally encounter concerns that require effective strategies for detection and resolution. Here, we’ll explore some of these common issues, their causes, and tips for troubleshooting them.

Heat Generation and Overload

Excessive heat generation is one of the most common issues that can affect squirrel cage motors. Overloads, imbalanced voltages, or poor ventilation can cause the motor to overheat, which can result in premature wear, insulation degradation, or, in extreme cases, motor failure.

Detection: Tools such as infrared thermal cameras or temperature probes can be used to monitor the motor’s surface temperature over time. A sharp rising trend or higher-than-normal steady-state temperature may indicate an overheating issue.

Prevention: Ensuring that the motor is adequately sized for the load it’s driving is a proactive way to prevent overheating. Regular inspections to ensure the motor’s cooling system (air flow, cooling fins, fan) is clean and functional can also keep heat in check. Lastly, ensuring balanced voltage across power supply lines can prevent heat-generating unbalanced currents.

Addressing the issue: If overheating is detected, check for overloads or confirm whether the motor is properly sized for its load. It may be necessary to clean the motor, specifically the ventilation and cooling parts, or to remediate power supply issues. In severe cases, the use of an external cooling system or resizing the current motor may be required.

Noise and Vibration Issues

Noise and vibration in a squirrel cage motor can be indicative of various problems, including misalignment, bearing issues, or possible shaft or structural deformities.

Detection: Unusual noise or excessive vibration can often be detected during routine checks. Tools such as stroboscopes and vibration analyzers can provide precise measurements and help diagnose the problem.

Solving the Problem: Misalignment can often be corrected by realigning the motor with its load. Bearing issues might require lubrication or, in severe cases, replacement. Structural issues could necessitate a more comprehensive repair—or even full replacement—of the motor.

Starting Problems

Starting issues, such as slow starting or failure to start, are often associated with power supply problems, mechanical resistance, or issues related to the motor’s starter circuit.

Detection: A motor that fails to achieve the required speed, or not starting at all, is a clear sign of a starting problem.

Troubleshooting: Check for correct voltage at the motor terminals during start-up. If there’s an issue, the supply line or power source may be the problem. High mechanical resistance could mean the motor is under too much load during starting, or there could be blockage of some kind. Checking the motor’s starter circuit, including the connections and all components, can also reveal issues hampering the starting sequence.

By learning to spot these common concerns and employing these troubleshooting tips, you can considerably reduce downtime, improve productivity, and extend the lifespan of squirrel cage motors—all of which contribute to maintaining operational efficiency.

The Future of Squirrel Cage Motors

As the world continues to evolve and modernize, so do the technologies powering our industries, homes, and the devices we use daily. Squirrel cage motors, as a cornerstone of electromechanical energy conversion, are no exception. Looking ahead, we can anticipate continuing advancements in their design and functionality, as well as an increasing focus on their role in sustainable practices.

Technological Advancements

Future improvements in squirrel cage motor technology are expected to center around enhancing efficiency, longevity, and control.

Drivers for increased efficiency include not only the cost savings from reduced energy consumption but also the less tangible—but important—benefits of reduced heat generation and decreased power infrastructure requirements. Leveraging advanced materials, refining the motor design, and innovating on manufacturing processes could push the efficiency envelope further.

Enhanced longevity could be achieved through improvements in materials used for windings and bearings, as well as refinement in motor cooling design. These changes could also contribute to extending maintenance intervals, thereby reducing the total cost of ownership and operation.

Finally, improvements in control technology, such as more sophisticated motor management software, could enable finer control over motor operation, lead to better integration with industrial automation systems, and provide more in-depth, real-time diagnostics.

Sustainability Aspects

As environmental concerns continue to take center stage in our global consciousness, squirrel cage motors’ role in sustainable energy practices will likely grow in magnitude. Improvements in motor efficiency can notably reduce power consumption; since electric motors account for nearly half of the world’s electricity demand, even moderate efficiency gains could draw significant benefits in the form of energy savings.

Additionally, the development of squirrel cage motors using sustainable materials or methods could play a part in mitigating the environmental impact. Encouraging and adopting practices such as recycling motors at the end of their life cycle could also contribute to the sustainability agenda.

Finally, integrated renewable energy sources for squirrel cage motors could be an exciting frontier in sustainability. Combining squirrel cage motors with power electronics could enable seamless operation on renewable energy, drawn from solar arrays, wind turbines, or other environmentally friendly power sources.

As squirrel cage motors continue to play a fundamental role in a broad spectrum of applications, their evolution will undoubtedly align with technological advancements and sustainability goals, increasing their efficiency and lowering their environmental impact while addressing the ever-growing energy demands of our modern world.

Conclusion

From industrial giants to home appliances, squirrel cage motors prove to be indispensable elements in modern technology. With ongoing advancements and a push towards more sustainable practices, their future looks both bright and integral to industrial development.

FAQ about Squirrel Cage Motors

Q: What exactly is a squirrel cage motor?

A: A squirrel cage motor, often referred to as an induction motor, operates on the principle of electromagnetic induction. Unlike motors requiring external commutation, squirrel cage motors achieve rotation when an alternating current flows through their stator winding, creating a rotating magnetic field that induces a current in the rotor. The term “squirrel cage” comes from the rotor’s appearance, consisting of bars connected by rings at both ends, resembling a cage.

Q: Why are squirrel cage motors so popular?

A: Their popularity stems from several key benefits: they are relatively low in cost, robust, simple in construction, and free of brushes which minimizes maintenance. Furthermore, they can operate in hazardous conditions since they do not involve sparking parts. Their efficiency and reliability make them suitable for a wide range of industrial and commercial applications.

Q: Can a squirrel cage motor run on a single-phase current?

A: While squirrel cage motors are inherently designed for three-phase current, which provides a self-starting capability and more consistent torque, they can operate on single-phase power with the aid of a start capacitor or other starting mechanisms. However, these adaptations are typically less efficient and might not be suitable for all applications.

Q: How can you reverse the rotation direction of a squirrel cage motor?

A: The rotation direction can be reversed by changing the phase sequence of the supply power. This can be simply achieved by interchanging any two of the three-phase supply wires, which inverts the direction of the rotating magnetic field produced by the stator, causing the rotor to turn in the opposite direction.

Q: What causes a squirrel cage motor to overheat, and how can it be prevented?

A: Overheating can result from various factors, including overloading, voltage imbalances, and poor ventilation. Ensuring that the motor is correctly sized for its application can prevent overloading. Regular maintenance checks should include verifying the supply voltage is within the motor’s rated range and that the motor is free of dust and debris to ensure adequate cooling.

Q: How do you troubleshoot a non-starting squirrel cage motor?

A: Begin by ensuring the power supply is correctly connected and functioning. Check for blown fuses or tripped circuit breakers, and inspect the motor starter and overload relays. Additionally, assess the condition of the motor windings and capacitors (if applicable) for signs of damage or wear. Sometimes, mechanical binding or a seized bearing can also prevent the motor from starting, so these should be examined as well.

Q: Are squirrel cage motors energy efficient?

A: Squirrel cage motors are known for their high efficiency, especially models designed according to modern energy standards. High-efficiency or premium efficiency models are available that operate at even higher efficiencies, significantly reducing energy consumption and operating costs over the motor’s lifetime. However, the efficiency can vary depending on the size and specific design of the motor.