Welcome to a comprehensive guide that takes a deep dive into the world of Type K Slip Rings. This article covers their design, construction, performance, key features, popular applications, and maintenance tips. No matter if you’re a supplier, an end-user, or simply curious, this guide offers valuable insights for all.

Introduction to Type K Slip Ring

- Brief Overview of Slip Rings

Slip rings are electromechanical devices that facilitate the transfer of power, data, or electrical signals between stationary and rotating components within various systems. They are a pivotal solution for overcoming the limitations of cables or wires by permitting unrestricted 360-degree rotation. Their rotating contacts, or brushes, maintain a continuous connection to provide uninterrupted signal transmission.

- Introduction to Type K Slip Ring

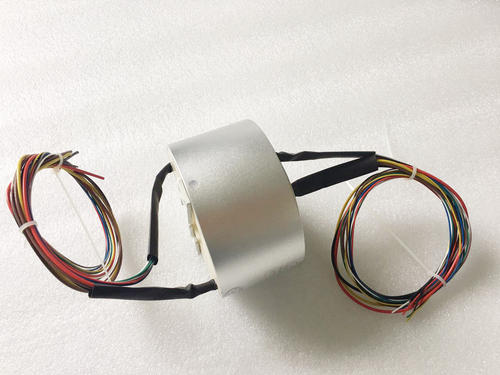

The Type K Slip Ring is a specialized variant known for its compact design and sturdiness, catering to a variety of applications. It is designed to operate reliably in diverse conditions, supporting an assortment of industries. Unlike traditional bulkier slip rings, Type K slip rings are engineered to cater to not only the transmission of power and data but also to do so in a more space and weight-efficient manner.

- Importance and Common Applications

Type K Slip Rings are crucial in applications where continuous rotation is required, and constraints like space, weight, and performance are critical factors. They enable power and signal transfer in devices or machinery across a variety of sectors such as renewable energy, medical technology, robotics, and heavy industries. By allowing these components to function seamlessly, Type K Slip Rings facilitate the smooth operation of critical systems, contributing to advancements in technology, productivity, and enhanced user experiences.

Design & Construction of Type K Slip Ring

- Structure and Materials

The Type K Slip Ring exhibits a superior, robust structure engineered to endure the demanding environments in which they often operate. Components commonly include precious metal brushes and rings, corrosion-resistant housing, high-purity copper alloy rings, and high-quality bearings for smooth rotation. These materials are meticulously chosen to guarantee efficient transmission, minimal electric noise, and long life.

- Number of Circuits

As an integral part of their design, Type K Slip Rings can offer multiple circuits for various types of signals and powers. The number of circuits can be customized based on specific needs, ranging from just a few to hundreds. Each circuit corresponds to individual connections that transfer specific signals or power levels, enabling Type K Slip Rings to support complex, multi-faceted operations through a single, streamlined device.

- Mounting and Installation

Installing a Type K Slip Ring is a straightforward process, generally involving the method of flange mounting. The compact design of these slip rings, combined with their lightweight, simplifies the installation process and allows for their utilization in systems with space limitations. However, precise installation is vital to ensure adequate performance and avoid premature wear or possible damage. The mounting procedure, although easy to follow, is recommended to be carried out by experienced personnel to ensure adherence to manufacturers’ guidelines and safety precautions.

Type K Slip Ring Electrical & Mechanical Performance

- Voltage and Current Ratings

Type K Slip Rings are designed to accommodate a wide range of voltage and current ratings. This adaptability positions them as an optimal solution for numerous applications with diverse power and signal transfer requirements. Voltage ratings can vary from a few millivolts to several thousand volts, whereas current ratings typically range from milliamps to hundreds of amps, depending on the specific demands of the system in which they are employed.

- Electrical Noise and Resistance

Minimizing electrical noise and resistance is vital for the effective performance of any slip ring, including Type K variants. The chosen materials, including precious metal brushes, high-purity copper alloy rings, and the layout of the contacts, contribute to reducing noise and resistance. These factors optimize signal integrity and overall reliability, which are especially significant for applications such as medical equipment or robotics, where precise transmission of data and control signals is critical.

- Speed, Torque, and Life Expectancy

Type K Slip Rings are celebrated for their impressive speed, torque, and life expectancy. They are designed to handle varying rotational speeds based on application demands, with some capable of reaching thousands of RPMs. Lightweight materials and carefully engineered construction ensure minimal torque during rotation, leading to reduced wear and tear. This combination of features, paired with proper maintenance, can yield an extensive life expectancy for Type K Slip Rings, spanning millions of rotations and providing excellent long-term value and reliability.

Type K Slip Ring Key Features & Benefits

- Compact Size and Low Weight

One of the distinguishing features of Type K Slip Rings is their compact size and low weight, making them suitable for applications with space constraints or strict weight limitations. This design advantage directly impacts the system’s overall efficiency, leading to reduced space and weight requirements for the equipment, alongside easier maintenance and installation processes. Ultimately, a Type K Slip Ring’s compactness allows for broader adoption across different industries and technologies without hampering other components’ functionality or the system’s dynamics.

- High-performance and Reliability

Another key aspect of Type K Slip Rings is their high performance and reliability, fulfilling the essential criteria of any slip ring application. Type K Slip Rings are built with quality materials and precision engineering, ensuring minimal electrical noise, low resistance, smooth rotation, and efficient transmission of power and signals. This attention to performance and durability, along with regular maintenance, ensures that Type K Slip Rings maintain their optimal functionality and have extended life expectancies, making them a reliable option for critical applications across various sectors.

- Wide Range of Customization Options

To cater to the diverse range of applications and industries, Type K Slip Rings offers numerous customization options. This flexibility includes the number of circuits for power and signal transmissions, the choice of mounting methods, the materials used for brushes and rings, and even the specific voltage and current ratings. The availability of these customization options ensures that Type K Slip Rings can be tailored to suit each application’s unique requirements, contributing to higher efficiency, increased compatibility, and overall better performance within the intended system.

Type K Slip Ring Popular Applications

Type K Slip Rings are versatile devices used across multiple industries due to their compact size, reliable performance, and broad customization options. Below are some notable applications:

Wind Turbines

In the field of renewable energy, wind turbines significantly benefit from the use of Type K Slip Rings. These devices ensure seamless transfer of electrical power and vital signals from the turbine’s rotating blades to its stationary control systems. They allow the wind turbines to rotate the full 360 degrees according to wind direction, optimizing power generation and efficiency.

Medical Equipment

The medical industry relies heavily on Type K Slip Rings, particularly in advanced imaging equipment like CT scanners and MRI scanners. In these machines, the slip rings enable the continuous rotational motion necessary for capturing high-resolution, three-dimensional images. Their compact size is ideal for the limited space within such advanced medical devices, while their high performance ensures precise and reliable data transmission.

Robotics

Robotics is another sector where Type K Slip Rings find substantial application. They are essential in maintaining the electrical continuity in robots during rotational movements, thus ensuring efficient power and data transfer. This is particularly crucial for automated manufacturing systems and robotic arms, where unobstructed, smooth movement paired with accurate signal transmission is pivotal.

Heavy Machinery

Type K Slip Rings are heavily utilized in various types of heavy machinery, such as rotating platforms, cranes, and excavators. They facilitate the transmission of electrical power and control signals between stationary and moving parts of these machines. This not only enhances the operation of these machines but also contributes to improved safety measures and extended machinery lifespan.

Type K Slip Ring Maintenance & Troubleshooting

- Preventive Maintenance and Cleaning Recommendations

To ensure the optimal performance and longevity of Type K Slip Rings, it is essential to carry out regular preventive maintenance. This includes routine inspections, cleaning, and lubrication. Some recommendations are:

- Inspections: Periodically check the wear of the brushes and replace them when required. Monitor the contacts for any signs of corrosion or pitting that could impact the electrical connection.

- Cleaning: To maintain an efficient signal transmission and prevent any debris from causing internal damage, the brush assembly and slip ring surfaces should be cleaned regularly, following the manufacturer’s guidelines. Use non-abrasive materials and appropriate solvents for the cleaning process. Avoid any contact with oil or grease, as they may lead to increased debris build-up.

- Lubrication: Proper lubrication improves the slip ring’s performance and lifetime. Lubricate the bearings according to the manufacturer’s instructions, using the recommended lubricant.

- Common Issues and Troubleshooting

Despite proper maintenance procedures, issues may still arise. Below are some common concerns and troubleshooting suggestions:

- Signal Loss or Fluctuation: If signal loss or fluctuations are encountered, inspect the brushes and contact surfaces for excessive wear or contamination. Clean or replace them accordingly. Additionally, ensure that electrical connections are secure.

- Increased Noise or Vibration: Noise and vibration could be symptoms of problems with the bearing, such as insufficient lubrication or wear. Check the bearing’s condition and lubricate or replace it if necessary.

- Poor Rotation or Rotation Stopped: If the slip ring doesn’t rotate smoothly or has stopped rotating, inspect the mounting to ensure proper alignment. Also, examine the bearings and brush pressure for proper functioning. Adjust or replace the components as needed.

When troubleshooting, always follow the manufacturer’s guidelines and recommendations, and if the issue persists, consult experts or the supplier for assistance.

Type K Slip Ring Market Trends & Manufacturers

- Market Growth and Demand for Type K Slip Rings

There has been a significant rise in demand for Type K Slip Rings, owing to their applications in various expanding industries such as renewable energy, healthcare, robotics, and heavy machinery. The growing emphasis on sustainable power generation, specifically wind energy, has led to a surge in demand for high-performing and reliable slip rings. Similarly, advancements in medical technology, along with an increase in automation industries and heavy machinery usage, are contributing to market growth.

Coupled with the ongoing industrialization and advancements in technology, the future market of Type K Slip Rings appears promising. The increasing requirement for customized slip rings with diverse specifications is also influencing manufacturers to diversify their product offerings, further fueling the market expansion.

- Leading Manufacturers and Suppliers

Several companies are leading the manufacturing and supply of Type K Slip Rings. These manufacturers are known for their high-quality products, extensive range of options, and adherence to industry standards. Please note that the mentioned companies are examples and not exhaustive.

- Moog Inc.: An eminent provider of high-performance slip rings globally, recognized for their customization options and competitive edge in catering to diverse industries.

- Schunk Group: Known for their robust, reliable, and long-lasting slip rings, Schunk Group is a prominent player providing solutions specifically tailored to individual customer needs.

- Stemmann-Technik: Renowned for their innovative slip ring solutions, Stemman-Technik offers a wide array of Type K Slip Rings suitable for application in various industries.

When choosing a supplier or manufacturer, it’s essential to consider factors such as their product range, expertise in the field, customization options, and after-sales services, along with the quality of their products and customer reviews.

How to Choose the Right Type K Slip Ring

- Factors to Consider When Selecting a Slip Ring

Choosing the correct Type K Slip Ring requires careful consideration of several factors. Ensuring compatibility with device requirements and environmental conditions, along with budgetary constraints, is essential for long-term effective operation.

This is a critical aspect when selecting a slip ring. Understanding the power needs of the equipment can guide the selection of a suitable device. If the requirement involves high voltage or current, it’s essential to opt for a slip ring designed to handle such loads without risk of overheating or reduced efficiency. Simultaneously, if the application requires data or signal transmission, the slip ring must also support these functions effectively.*

Environmental Factors

The operating environment plays a fundamental role in determining the suitable type of slip ring. For instance, harsh conditions such as extreme temperatures, moisture, and dust can significantly impact the slip ring’s operation. Devices installed in outdoor settings or exposed to such environments should have relevant protective features that can withstand these factors. This can include sealed enclosures for protection against dust and water or specialized materials for resistance against corrosion and extreme temperatures.*

Budget Constraints

Finally, the available budget plays a crucial role in the selection process. Buyers must aim to strike a balance between cost and quality. Although cost-saving can be tempting, choosing a low-quality slip ring may lead to higher costs in the long run due to frequent replacements or potential machine downtime. Purchasing from reputable manufacturers often ensures better quality and reliability, contributing to long-term cost-effectiveness.

By considering these factors, one can effectively identify the most suitable Type K Slip Ring that aligns with their specific requirements and expectations, ensuring efficient, reliable, and cost-effective operation.

Conclusion

To summarize, the Type K Slip Ring, with its dynamic features and applications, proves itself to be a remarkable device. Its importance and versatility extend across different industries, making it a topic worth deeper exploration. Users are encouraged to research further to determine the optimal Type K Slip Ring for their specific needs.

FAQs about Type K Slip Ring

Q: What are Type K Slip Rings used for?

Type K Slip Rings are used to transmit electrical power and signals between stationary and rotating parts in machinery. They find wide applications in industries such as renewable energy (particularly wind turbines), advanced medical equipment, robotics, and heavy-duty machines like excavators and cranes.

Q: How to maintain the performance of a Type K Slip Ring?

Regular preventive maintenance including routine inspections, appropriate cleaning, and lubrication extends the lifespan and improves the performance of Type K Slip Rings. Inspect the brushes and contact surfaces for wear or contamination regularly, and replace or clean them as necessary. Lubricate the bearings as per the manufacturer’s instructions using the recommended lubricant.

Q: What common issues may occur with Type K Slip Rings?

Common issues with Type K Slip Rings include signal loss or fluctuation, excessive noise or vibration, and poor or stopped rotation. These can often be resolved by inspecting and servicing various components like the brush assembly, bearings, and electrical connections as per manufacturer guidelines.

Q: How to choose the right Type K Slip Ring?

When choosing a Type K Slip Ring, factors such as current and voltage requirements of the equipment, environmental conditions of the operating setting, and budget constraints should be considered. It’s essential to balance the cost with quality and ensure the chosen product meets all requirements.

See What We Can Do