In this comprehensive guide, we explore the crucial role of the 3 Phase Slip Ring, delving into its design, functionality, and widespread applications in various industries. We will also highlight maintenance strategies, address common issues, and take a glance at emerging trends, ensuring you’re equipped with the knowledge to optimize these components for your projects.

Introduction to the 3-Phase Slip Ring

Understanding complex machinery components simplifies our interaction with the intricate world of technology. One such integral component, often disregarded due to its complexity, is the 3-phase slip ring.

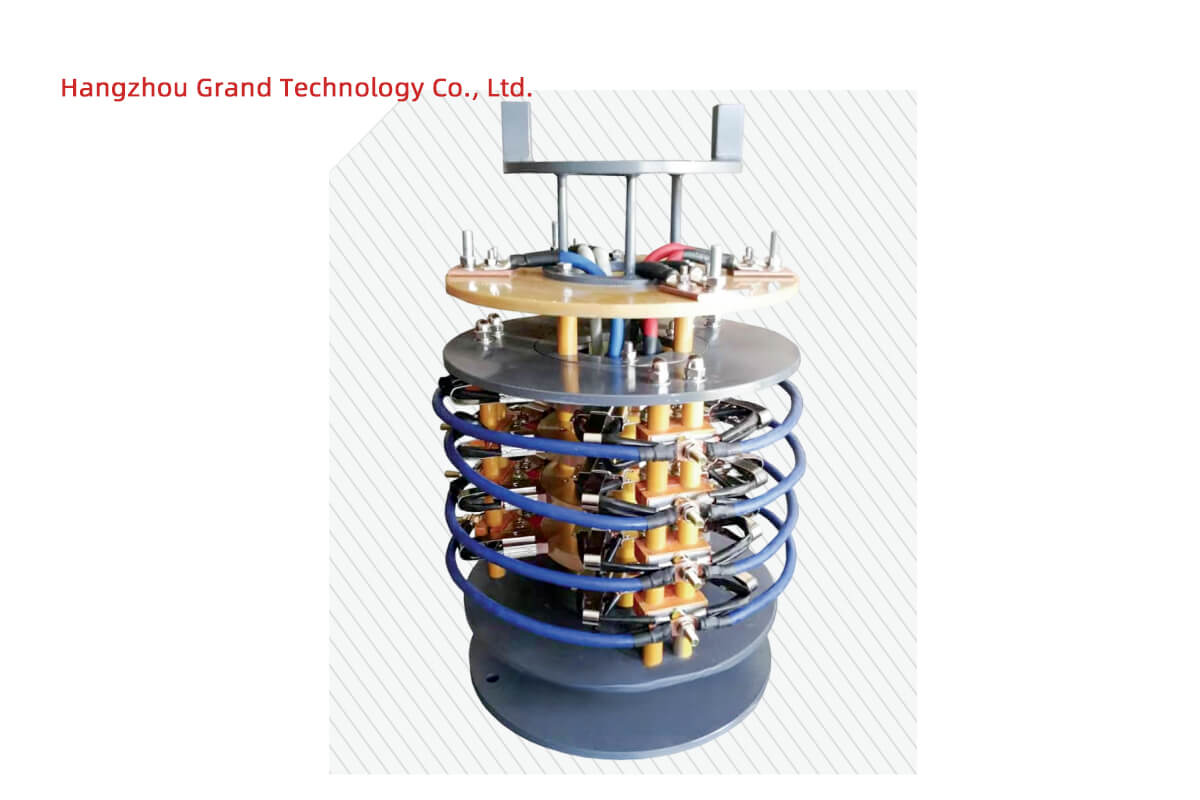

At its core, a 3-phase slip ring is an electromechanical device that allows the transfer of power and electrical signals from a stationary part to a rotating part in a machinery. This transmission is made possible using brushes and rotating contacts, generically described as “rings.” The unique aspect of a 3 phase slip ring is its ability to handle three electrical circuits simultaneously – a trait that makes it a practical choice for equipment that demands a more balanced power transmission and the ability to handle high loads effectively.

The relevance of these 3 phase slip rings, particularly in the context of electrical systems and rotating equipment, is undeniable. When we look at a wide array of machines – be it industrial, medical, or wind turbines – they consist of components rotating continually, requiring both power and signal delivery. For instance, in the arm of a robotic assembly or the rotor of a wind turbine, parts continually rotate while needing a stable supply of power for optimal functionality. Here, slip rings come to the fore, providing a seamless and continuous transfer of electrical power and signals, all while keeping system performance robust.

This seemingly simple, yet intricate device, transforms the operations of many systems around us. It allows uninterrupted operations in a myriad of equipment, improving their performance and capabilities. By connecting stationary sources to parts that keep moving, the 3 phase slip rings not only unlock new realms of possibilities but also underpin the very fundamentals that keep our world rotating – quite literally.

3 Phase Slip Ring Basic Concept and Design

To understand the inner workings of rotating machinery and advanced technological equipment, familiarizing yourself with the foundational principles of a slip ring is crucial. A slip ring is an electromechanical device designed to ensure uninterrupted electrical conductivity between a stationary source and a rotating component. It enables a transfer of power, data, or signal from a fixed apparatus to a rotating part without the risk of tangling wires. This transference is achieved using sliding contacts or brushes on continuous rings.

Delving into the design of a 3-phase slip ring, we come across an even more specialized unit. Evolving from the basic concept of a slip ring, a 3 phase slip ring is explicitly designed to deal with three-phase power systems. In a 3 phase slip ring, there are typically three conductive rings, each dedicated to handling a different phase of the electrical current. To achieve this, conductive brushes slide over these rings, ensuring an undisrupted flow of current.

Distinguishing between a single-phase and a 3 phase slip ring rests on understanding the handling capacity of electrical circuits. In simple terms, a single-phase slip ring is designed to manage a single electrical circuit. It is commonly used in lower-power applications where the demand isn’t as high. Contrarily, a 3 phase slip ring possesses the ability to handle three electrical circuits simultaneously. This unique feature makes it an ideal choice for systems that demand balanced power transmission and are of a high-power nature, thereby offering higher efficiency and performance.

By grasping the designed rationality and operational characteristics of a 3-phase slip ring, we gain a deeper understanding of its vital role in facilitating complex operations – enhancing efficiency and system longevity in myriad applications. fine-tuning the technology behind the simple rotation of machinery parts is integral to the evolution of electric systems and rotating equipment on the whole.

3 Phase Slip Ring Operational Principles

To fully appreciate the intricacies of modern rotating equipment, one must delve into the operational principles of the 3 phase slip ring, an essential component that lies at the heart of such technology.

Imagine the 3 phase slip ring as a dynamic bridge, masterfully crafted to establish a seamless and consistent link between a fixed system and a freely rotating one. At its core, it employs a series of rings and brushes – each meticulously arranged to correspond with the phases of electrical current it is designed to carry. When power is applied, these rings revolve in unison with the rotating component of the machine, be it a wind turbine blade or a medical scanning device, all while the brushes maintain a static position. As the rings move, the brushes skim the surface, creating a circuit that allows electrical currents to flow unimpeded despite the rotational motion.

The electrical transfer within a 3-phase system gains its robustness from the unique configuration of the slip ring. 3 phase electric power is a common method for alternating current electric power generation, transmission, and distribution. It is a type of polyphase system and is the most common method used by electrical grids worldwide to transfer power. Inside the housing of a 3 phase slip ring, the three individual rings are wired to each of the three phases in this system. Thus, as the assembly turns, each phase continually feeds power through its designated ring and corresponding brush, ensuring that the rotating section of machinery is evenly and reliably powered.

The brushes play a pivotal role in this dynamic interplay, serving as conductors that maintain the electric current’s continuity. They are typically made of materials such as graphite or precious metal alloys, chosen for their conductivity and durability. As these brushes softly graze the rotating rings, they wear down over time due to friction—yet they are designed to do so in a controlled manner, ensuring a long service life and consistent performance. The key to an uninterrupted electricity supply lies in the careful orchestration between these spinning rings and their unwavering brushes – it is a dance that keeps the electric current flowing smoothly, thus enabling the system’s operational integrity.

Through understanding the operational principles of a 3 phase slip ring, we open a window into the sophisticated realm of rotary joints and mechanical systems, revealing the delicate balance between motion and power transmission encoded into their design.

Key Components of 3-Phase Slip Ring

A three-phase slip ring is composed of several key components that work together to enable the transfer of electrical power and signals between stationary and rotating parts of a machine. Understanding these components helps in appreciating how the slip ring functions and what factors contribute to its performance and reliability.

- Rotor (Rotating Part):

- The rotor is the part of the slip ring that rotates along with the machinery. It usually consists of conductive rings (often made of copper or a similar material) mounted on an insulating shaft. Each ring corresponds to one phase of the three-phase system and is responsible for transmitting electrical power from the stationary brushes to the rotating equipment.

- Stator (Stationary Part):

- The stator is the stationary part of the slip ring assembly. It typically holds the brushes or contact elements that remain in fixed contact with the rotating rings. The stator connects to the external power source and delivers the current through the brushes to the rotor.

- Brushes:

- Brushes are typically made of carbon, graphite, or metal alloys and are designed to maintain continuous electrical contact with the rotating rings of the rotor. They slide against the rings as the rotor turns, enabling the transfer of electrical power or signals. The quality of the brushes greatly affects the efficiency and lifespan of the slip ring.

- Slip Rings (Conductive Rings):

- The slip rings themselves are the conductive paths that the brushes contact. These rings are usually made of a highly conductive material like copper or brass, often coated with a layer of gold, silver, or other metals to improve conductivity and reduce wear.

- Insulation:

- Insulation materials are critical in a three-phase slip ring, ensuring that the conductive rings are electrically isolated from each other and from the shaft. The insulation must be durable and capable of withstanding the operational temperature range and environmental conditions.

- Housing:

- The housing of the slip ring protects the internal components from environmental factors such as dust, moisture, and mechanical damage. The housing is often made from materials like aluminum, stainless steel, or engineered plastics, depending on the application requirements.

- Bearings:

- Bearings are used to support the rotor and ensure smooth and stable rotation within the housing. High-qual

- Terminals or Leads:

- Terminals or lead wires extend from the slip ring to connect the device to external circuits. These connections must be secure and capable of handling the required voltage and current without degradation over time.

- Seals and Gaskets:

- Seals and gaskets are used to protect the internal components from contaminants and to maintain the integrity of the slip ring in harsh environments. They contribute to the overall IP rating of the device.

- Mounting Flange:

- The mounting flange is the interface used to secure the slip ring assembly to the machine. It provides a stable connection between the slip ring and the equipment, ensuring proper alignment and operation.

Each of these components plays a crucial role in the overall function and performance of a three-phase slip ring, and the quality and design of these components determine the slip ring’s suitability for various industrial applications.

3 Phase Slip Ring Key Features and Specifications

To appreciate the vital role that 3-phase slip rings play in the vast theatre of mechanical and electrical engineering, one must understand their construction and key features. The careful selection of materials and the precise engineering of specifications are what enable 3-phase slip rings to operate reliably under various conditions.

The materials chosen for the construction of 3-phase slip rings are pivotal to their performance. Manufacturers often use noble metals such as gold, silver, and their alloys for the rings due to their excellent electrical conductivity and resistance to corrosion. However, for more industrial and heavy-duty applications, you might find materials such as copper, brass, or even aluminum, chosen for their combination of good conductive properties and physical durability. The brushes are typically made from graphite or precious metal alloys, which provide a good balance between conductivity and wear resistance, ensuring long-lasting electrical contact.

Key Features

- High Power Capacity:

- Designed to transmit high levels of power, making them suitable for industrial and heavy-duty applications.

- Compact Design:

- Despite handling high currents, three-phase slip rings are often designed to be compact to fit into various mechanical assemblies.

- Low Electrical Noise:

- Engineered to minimize electrical noise, ensuring stable and reliable transmission of power and signals.

- Durable Construction:

- Built with high-quality materials to withstand harsh environments, including high temperatures, moisture, dust, and vibrations.

- Smooth Rotational Performance:

- Provides consistent and smooth rotation, which is crucial for maintaining the integrity of electrical connections during operation.

- Multiple Circuit Options:

- Can be configured to include additional circuits for data, signals, or other power requirements beyond just the three-phase power.

- Customizability:

- Many three-phase slip rings can be customized in terms of size, number of circuits, and type of connection to meet specific application needs.

- Maintenance-Free Operation:

- Designed for long-term use with minimal maintenance, often featuring self-lubricating materials or sealed designs.

As for the common specifications, they are the language through which engineers communicate and match slip rings to their appropriate applications. The voltage rating is the maximum voltage the slip ring can handle without the risk of electrical breakdown between the rings. The current capacity refers to the maximum current each ring can conduct continuously without overheating or degrading. Together, these factors determine the overall power-handling capability of the slip ring.

The rotational speed is a further critical specification. It defines the maximum number of revolutions per minute (RPM) the slip ring assembly can withstand. This is particularly important in assessing their suitability for different applications. For example, a slip ring in a high-speed turbine will require a higher rotational speed capability than one used in a slower-rotating security camera.

Specifications

- Voltage Rating:

- Typical voltage ratings can range from 100V to several kilovolts, depending on the application.

- Current Rating:

- Current capacity may vary from a few amperes to several hundred amperes per circuit.

- Operating Speed:

- The rotational speed is usually specified in RPM (revolutions per minute), with typical ratings ranging from 100 RPM to 5000 RPM or more, depending on the design.

- Insulation Resistance:

- Insulation resistance is crucial for safety and reliability, often specified in megaohms (MΩ), typically 100MΩ or higher at 500VDC.

- Dielectric Strength:

- The dielectric strength indicates the slip ring’s ability to withstand high voltage without breakdown, often measured in kilovolts (kV).

- Contact Material:

- Common contact materials include precious metals like gold or silver or composite materials designed to reduce wear and enhance conductivity.

- Temperature Range:

- Operating temperature ranges vary, with common specifications ranging from -40°C to +80°C, although some slip rings are designed for extreme environments and can operate beyond these limits.

- Environmental Protection:

- Many slip rings come with IP ratings (e.g., IP65, IP67) indicating their resistance to dust and water ingress, making them suitable for outdoor or harsh environments.

- Housing Material:

- The housing is typically made from materials like aluminum, stainless steel, or engineering plastics, depending on the required durability and environmental exposure.

- Number of Circuits:

- Besides the three primary power circuits, slip rings can include additional circuits for data transmission, signals, or even fluid channels, depending on the design.

These key features and specifications collectively dictate the performance and potential applications of 3-phase slip rings. A higher voltage and current capacity will suit industrial environments with heavy power loads, while a slip ring engineered for higher rotational speeds will find its place in equipment that requires fast, swift movement.

Understanding how these properties interplay is crucial for system designers and engineers. The meticulous calibration of materials and specifications ensures that each slip ring can meet the specific demands of its intended application, be it in delicate medical imaging equipment or the rigorous and punishing environment of wind turbine power generation. In sum, the ‘anatomy’ of a 3-phase slip ring is a testament to the precision engineering that supports and enhances the technologies we rely on every day.

Advantages of Using 3-Phase Slip Rings

The integration of 3-phase slip rings into the machinery is not just a technological choice; it’s a strategic decision that opens up a plethora of benefits, enhancing both the performance and the operational efficiency of the systems. Their design, centered around the principles of 3-phase power transmission, leverages the inherent advantages of this power method, thus offering significant improvements in power handling capabilities and flexibility.

One of the primary benefits of using 3-phase slip rings is their superior power handling capabilities. By distributing the electrical load across three distinct phases, these slip rings can transmit more power compared to their single-phase counterparts. This distribution not only allows for the delivery of a higher power output but does so with a lower current requirement for each phase. Consequently, this reduces the strain on individual components, leading to increased longevity and less thermal stress on the system.

Moreover, the flexibility in power transmission that 3-phase slip rings offer is unparalleled. This flexibility facilitates the transfer of power to a wide range of rotating platforms without the need for extensive modifications or custom solutions. Whether it’s for a wind turbine requiring steady and scalable power delivery as it adjusts to wind speeds, or for rotating machinery in the manufacturing sector needing precise control and distribution of power, 3-phase slip rings adapt seamlessly to diverse operational demands.

The reliability and efficiency in transmitting power to rotating platforms also set 3-phase slip rings apart. The balanced nature of 3-phase power reduces vibrations and provides a smoother operation of machinery. This inherent balance ensures that power is continuously available, even if one phase experiences a drop, minimizing downtime and enhancing operational reliability. In the context of efficiency, these slip rings ensure a consistent energy supply with minimal energy loss, thanks to the optimized electrical contacts and reduced electrical resistance achievable within the three-phase system setup.

In essence, the advantages of using 3-phase slip rings extend far beyond just improved power handling and transmission. They contribute significantly to the reliability and efficiency of power distribution in rotating platforms, making them indispensable in applications where uninterrupted power supply and operational precision are critical. By harnessing these strengths, industries can optimize the functionality of their rotating equipment, ensuring smoother operations, reduced maintenance costs, and enhanced overall performance.

3 Phase Slip Ring Applications

The essence of a 3-phase slip ring lies not just in its design but also in its versatility of application. From industrial machinery to wind turbines, medical equipment, and robotics, its use is pivotal to the seamless function of a broad spectrum of rotating equipment.

Industrial machinery is perhaps one of the most common places where you’ll find 3-phase slip rings in action. Complex production equipment often involves rotating elements for a range of functions, from packaging to assembly lines. The use of 3-phase slip rings in such settings enables the machines to operate at different power levels, ensuring a steady, uninterrupted flow of electricity that is essential for the machinery’s uninterrupted and efficient operation. By allowing such flexibility in power transfer, they significantly contribute to the productivity and effectiveness of industrial operations.

In the renewable energy sector, wind turbines stand as prime examples of the intended usage of 3-phase slip rings. These massive structures, constantly rotating with the changing wind, need constant, reliable power to crucial components such as sensors, controllers, and pitch adjustment systems. The 3-phase slip rings work majestically here, transferring power, and capturing data from the rotating blades, effectively improving performance and ensuring smooth, continuous operation.

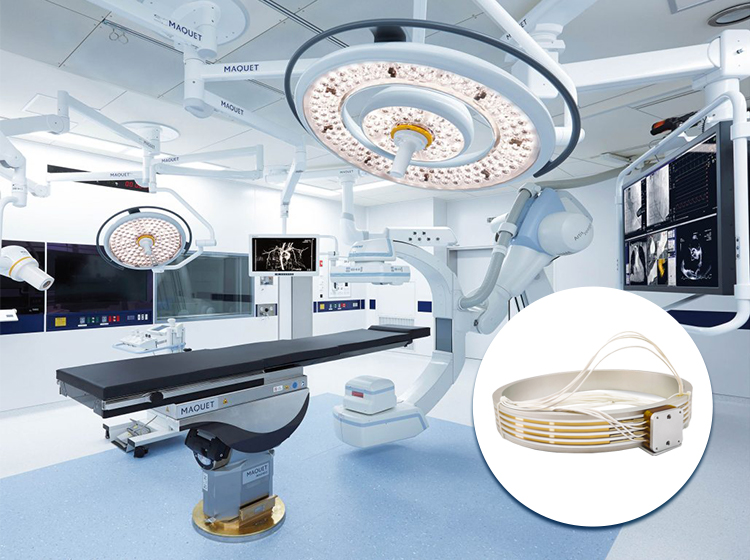

When it comes to medical equipment, precision and reliability are of utmost importance, and 3-phase slip rings contribute significantly to both. In advanced machinery such as CT scanners, 3-phase slip rings empower the revolving gantries, delivering power and transmitting data from many channels simultaneously and reliably. Given the critical nature of this equipment, the role of 3-phase slip rings in ensuring consistent performance and enhancing patient safety is truly paramount.

Finally, in robotics, 3-phase slip rings play a vital role, especially in robots designed for highly dynamic automated processes. These slip rings provide a continuous, stable power supply to the moving parts while supporting the transmission of control signals and feedback. Their inclusion allows robots to operate without restraint, bringing about improved operation efficiency, precision control, and enhanced automation.

Across these various applications, the significance and impact of 3-phase slip rings are beyond question. They not only cater to the unique power needs of different systems but also contribute substantially to improving operation efficiency, system reliability, and ultimately, the success of the application in question. It’s a testament to the transformative power of a simple, yet expertly engineered solution to the challenge of powering a varied range of rotating machinery.

3 Phase Slip Ring Installation and Maintenance

Ensuring the efficient operation and prolonged service life of 3-phase slip rings necessitates strict adherence to best practices in installation and maintenance. A meticulous approach not only mitigates potential operational hiccups but also enshrines the integrity and reliability of these critical components within various applications.

Installation Practices:

The optimal performance of a 3-phase slip ring is largely contingent upon its proper installation. First and foremost, it’s imperative to ensure that the slip ring assembly is compatible with the specific requirements of the application in terms of voltage, current, and rotational speed capabilities. Before installation, a thorough inspection should be conducted to check for any possible defects or damage incurred during transportation.

Accurate alignment of the slip ring with the rotating shaft is critical; misalignment can lead to uneven wear and tear on the brushes and rings, significantly diminishing the system’s efficiency and lifespan. Secure mounting in a manner that minimizes vibration will also contribute significantly to the slip ring’s performance and durability.

Electrical connections must be meticulously planned and executed. Using the correct gauge of wire for the expected current load, ensuring solid and clean contacts, and employing proper insulation are all vital steps to prevent electrical failures and fire hazards.

Maintenance Tips:

Routine maintenance is essential to sustain the operational efficiency and longevity of 3-phase slip rings. Regular inspection and cleaning of the rings and brushes to remove dust, debris, and any signs of corrosion are fundamental practices. This not only ensures optimal electrical contact but also prevents premature wear.

Monitoring the wear of the brushes forms a significant part of the maintenance routine. Brushes worn down to their minimum recommended length should be replaced promptly to avoid damage to the rings and potentially more serious electrical faults.

Environmental considerations are also crucial. Ensuring that the slip ring is protected from harsh environmental conditions such as moisture, excessive dust, and corrosive chemicals can prevent many common issues that lead to malfunction or failures.

Troubleshooting Practices:

Common problems with 3-phase slip rings often manifest as power fluctuations, intermittent signal transmission, or complete loss of power. Initial troubleshooting steps should include verifying the integrity of electrical connections and assessing the wear of brushes and the condition of the rings. If electrical connections are loose, corroded, or otherwise compromised, they should be cleaned, tightened, or replaced as needed.

If excessive wear or damage to the brushes or rings is observed, replacing the affected components will often restore normal operation. For issues that persist beyond these initial checks, a deeper investigation into the alignment, mounting stability, and the environmental conditions affecting the slip ring may reveal more complex underlying issues.

Adhering to these guidelines for proper installation, maintenance, and troubleshooting practices ensures not only the reliability and performance of 3-phase slip rings but also safeguards the broader systems they serve. By preemptively addressing potential issues and maintaining an unwavering commitment to these practices, the seamless operation of machinery and equipment relying on 3-phase slip rings is markedly enhanced.

3 Phase Slip Ring Emerging Trends and Future Directions

The continuously evolving industrial landscape is propelling innovations in 3-phase slip ring technology, shaping the trajectory towards efficiency maximization, durability enhancement, and broader applicability. A review of current trends, innovative directions, and future possibilities illustrates an exciting future for these vital components.

Current Trends:

As technology progresses, demands on 3-phase slip rings have led to distinctive trends in their design and usage. One such trend is the move towards higher-speed capability; more applications now require reliable power and signal transition at high rotational speeds, pushing designs towards better performance under increased velocity conditions.

The convergence of power and signal transfer within a single slip ring system is another prominent trend. Integrations of diverse signal types like Ethernet, video, and other data alongside standard power transmission are becoming essential in modern applications.

The rise in the recognition of their importance for renewable energy applications, like wind turbines, is also a trend to be noted. As renewable energy becomes more central to global power generation strategy, 3-phase slip rings will likely continue to gain prominence.

Ready to place an order? Provide your details and we’ll get back to you shortly.

Innovations for Durability and Efficiency:

Technological innovations are improving key aspects of 3-phase slip rings. Increasing usage of advanced materials for contacts, like precious metals or engineered composites, is contributing to their longevity and better signal transmission. Additionally, improvements in brush and ring design offer less friction, reducing wear and tear and thus enhancing the overall lifespan of the system.

Efficiency is another area shaping innovations. The development of low-resistance, high-conductivity electrical contacts, and improved insulation materials are reducing electrical losses in slip rings.

Future Directions:

Looking to the future, one may predict further miniaturization of 3-phase slip rings, catering to the growing demand for compact and efficient components in various industries. The integration of smart features to monitor parameters like wear, temperature, and power quality, empowering predictive maintenance, will likely become more prevalent.

The expanding realm of robotics and automation also provides a glimpse into the future of slip ring applications. As robots become more complex and autonomous, efficient and compact slip rings able to transfer power, control signals, and data will be in high demand.

Overall, the future of 3-phase slip rings appears dynamic and promising. As advances in materials, designs, and applications continue to emerge, these versatile power transfer components are poised to play an even more crucial role in a myriad of industries. Regardless of the directions these developments might take, the quest for improved efficiency, reliability, and adaptability will undeniably remain at the core of 3-phase slip ring technology.

Conclusion

3 Phase Slip Rings are instrumental in numerous electromechanical systems, providing essential power and data transfer capabilities for rotating structures. As technologies advance, staying informed on best practices in application and maintenance becomes more critical. Understanding these will ensure optimal performance and longevity of your equipment.

FAQs about 3-Phase Slip Ring

Q: How do I correctly size a 3-phase slip ring for my application?

A: Sizing a slip ring involves understanding the current requirements, voltage specifications, and mechanical constraints of your application. Consulting with a slip ring specialist is recommended.

Q: What are the signs of a failing slip ring?

A: Look for excessive noise, a drop in performance, or physical wear on the brushes and rings. These can indicate it’s time for maintenance or replacement.

Q: How can maintenance requirements for slip rings be reduced?

A: Opt for slip rings with advanced materials and design features aimed at reducing wear and tear, and establish a routine maintenance schedule to extend the life of the slip ring.

Q: What safety considerations should be kept in mind when handling and operating 3-phase slip rings?

A: Safety is paramount when dealing with any electrical equipment, including 3-phase slip rings. Always ensure that the power supply is turned off before performing any installation or maintenance activities. It’s important to use insulated tools to prevent accidental short circuits. Regular inspection for damage or wear, and compliance with manufacturer guidelines for installation and maintenance, can also significantly reduce the risk of accidents or equipment failure.

Q: How can concerns regarding wear and tear, especially on the brushes and contacts, be addressed?

A: Wear and tear, particularly on brushes and contacts, are unavoidable due to the physical nature of their operation. However, selecting slip rings with high-quality, wear-resistant materials can slow down this process. Ensuring correct alignment and installation to prevent undue stress and using slip rings within their specified operational parameters can also mitigate wear. Predictive maintenance, based on regular inspections to identify and address wear before it leads to failure, is another effective strategy.

Q: What causes noise and signal interference in slip rings, and how can it be minimized?

A: Noise and signal interference in slip rings often result from electrical or mechanical mismatches, such as poor grounding, electromagnetic interference, or physical wear affecting the contacts. To minimize these issues, use slip rings with proper shielding, maintain good grounding practices, and ensure that contacts are clean and well-maintained. Selecting slip rings designed for low electrical noise can also be crucial, especially in sensitive applications.

Q: How to properly size a 3-phase slip ring for specific applications?

A: Proper sizing of a 3-phase slip ring involves considering the maximum current and voltage requirements of your application, as well as the number of circuits needed for power and any signal/data transmission. Additionally, account for the environmental conditions (temperature, humidity, etc.) and mechanical constraints (size, mounting requirements). Consulting with the manufacturer or a qualified engineer can provide valuable guidance in selecting an appropriately sized slip ring.

Q: What are the signs of a failing slip ring?

A: Common signs of a failing slip ring include erratic operation or fluctuations in power/signal transmission, visible wear or damage to brushes and contacts, unusual noise during operation, and increased electrical resistance measured across the slip ring. If any of these signs are observed, a thorough inspection and possibly replacement of the affected components are advised.

Q: How to reduce maintenance requirements for slip rings?

A: Reducing maintenance requirements for slip rings centers on selecting high-quality equipment designed for specific applications and environmental conditions from the outset. Utilizing slip rings with advanced materials for contacts and brushes can minimize wear. Incorporating designs that facilitate easy access for inspection and cleaning can also lessen the maintenance burden. Implementing a scheduled maintenance plan, rather than waiting for signs of failure, helps in maintaining optimal operation with less frequent interventions.

See What We Can Do