The ever-evolving industrial landscape consistently seeks efficient solutions. Among these innovative technologies lie rotary union slip rings—an integral component enhancing seamless data transfer in rotating equipment.

Introduction to Rotary Union Slip Rings

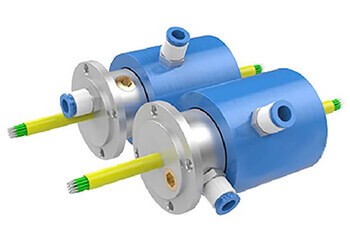

In the world of mechanical and electrical engineering, a rotary union slip ring emerges as a remarkably clever and reliable solution. This ingenious device is an electromechanical component that enables the transmission of power and electrical signals from a stationary to a rotating structure. In other words, it acts as an interface between a moving part and a stationary source of power or data, easing the transfer without limiting the angular rotation.

One might picture the simple example of a rotating display stand with internal lighting: the lights need power, but they turn continuously. A wire from a static source would quickly become tangled, but a slip ring solves this issue elegantly, allowing power to be delivered to the revolving parts without interruption.

The applications of rotary union slip rings, however, extend far beyond lighting a rotating display. They are widely used in a plethora of industries including manufacturing, security systems, wind energy, and even space satellites. Equally useful in CCTV cameras and CT scanners, they are versatile, thus universally present across various commercial and industrial technologies.

The rotary union slip ring has proven to be an indispensable asset in today’s industrial landscape. As industries strive for greater automation and efficiency, the need for uninterrupted power and data transmission becomes critical. In this regard, rotary union slip rings play a pivotal role in ensuring smooth operations and continuous performance of rotating equipment, thereby placing themselves as a vital cog in the machinery of technological and industrial progress.

Functional Principle of Rotary Union Slip Rings

To appreciate the utility of rotary union slip rings, it is important to understand their functional principle.

A rotary union slip ring comprises mainly two parts – the stationary part (stator) and the rotating part (rotor). These two parts are typically linked with a brush and ring system. The stator, connected to the data and power source, holds brushes—conducting components that maintain physical contact with rotating rings attached to the rotor. The electrical signals or power are effectively passed from the brushes to the rings and, consequently, from the stationary source to the rotating part of the equipment.

Inside the shell of the slip ring, the individual rings are insulated from each other, typically arranged concentrically. Each ring corresponds to a single channel of either data or power transmission. The brushes, sliding over these rings as the rotor rotates, ensure a continuous electricity or signal flow, thereby enabling features such as uninterrupted video in surveillance cameras, constant communication with rotating satellites, or provision of reliable power to wind turbines, regardless of their orientation.

On a technical note, the key components of rotary union slip rings include conductive rings, brush blocks, housing, and possibly a central shaft or bore. The rings and brushes are the most vital as they carry out the fundamental task of electricity or data transmission. Various materials like copper or precious metals are often used for rings and brushes to ensure better conductivity and longer life.

The specific designs and components can greatly vary depending on the specific applications, requirements for data or power volume, survival in harsh environments, and the operational lifetime. Indeed, the seemingly simple principle of a slip ring leverages intricate engineering and precise manufacturing to carry out the crucial function of unhindered signal and power supply to moving equipment elements.

Key Features of Rotary Union Slip Rings

Rotary union slip rings carry several distinct features that set them apart from other electrical components, and these distinguishable traits make them integral to many modern applications.

Firstly, a significant attribute of the rotary union slip rings is their ability to transmit both power and data simultaneously. This dual transmission capacity enables machines and systems to uphold smooth operation even in a rotational motion setting. It allows a seamless flow of electricity to power devices while also ensuring that data is transferred without interruption.

Durability is another key feature of these slip rings. They are designed and built to withstand long periods of use while still functioning effectively. The superior construction and the utilization of robust materials ensure they are hardwearing and have a long service life – an essential property for many industrial, military, and space applications where downtime can be costly.

Moreover, these slip rings are resistant to various environmental factors. They can operate in wide temperature ranges, withstand moisture, and resist dust. Many designs are intended specifically for harsh environmental conditions, making them suitable for use in sectors such as wind energy, marine, and heavy industry.

Material selection is an integral part of the design and production of rotary union slip rings. The choice of materials generally revolves around ensuring excellent conductivity, reduced friction, and minimal wear and tear. Commonly, precious metals like gold, silver, or platinum are used as contact materials between brushes and rings due to their superior conductivity and resistance to corrosion. The housing materials, typically aluminum or stainless steel, are selected for robustness, lightness, and resistance to harsh environments.

In sum, the ability to transmit power and data, robustness against intensive utilization, resilience under various environmental conditions, and strategic material selection for purpose-specific benefits collectively make the rotary union slip rings an incredible innovation. It is these features that have earned them a broad spectrum of applications in diverse areas, proving their indispensability and versatility across industrial landscapes.

Applications of Rotary Union Slip Rings

Rotary union slip rings are integral across an array of industries, thanks to their reliable power and data transmission capabilities for rotating equipment. Here, we discuss some prominent applications and examples, highlighting their versatility and significance.

Wind Energy

In wind turbines, rotary union slip rings facilitate the continuous transfer of power and data signals between the stationary nacelle and rotating blades. They enable the optimal performance of wind turbines by ensuring a seamless flow of current and smooth monitoring of data from sensors on the blades—essential for efficient power generation, maintenance, and troubleshooting.

Automotive Industry

Modern vehicles incorporate an array of rotating components, such as steering wheel controls and electric vehicle motors. Rotary union slip rings enable the transmission of electrical signals from stationary to rotating parts, ensuring uninterrupted control inputs and communication within the vehicle system.

Medical Sector

CT scanners, MRI machines, and X-ray devices all use rotating components in imaging processes. Rotary union slip rings ensure uninterrupted power supply and data transmission between the stationary controlling unit and the rotating sections of these machines, making it possible to obtain accurate and detailed imaging in diagnostic procedures.

Military Applications

In radar systems, the antenna continuously rotates to keep track of moving targets. These systems require uninterrupted power and data transmission to function effectively. Rotary union slip rings readily fulfill these requirements, aiding in efficient tracking, data processing, and system control for critical defensive purposes.

Security and Surveillance

Surveillance cameras often rotate 360 degrees to monitor expansive areas. Rotary union slip rings allow for continuous power and signal transmission, ensuring smooth navigation and real-time data transfer in security applications.

Industrial Automation

Robotic arms, automated assembly lines, and packaging systems, all of which predominantly use rotating parts, benefit significantly from the capabilities of rotary union slip rings. Their seamless power and data transmission ensure the uninterrupted operation of these automated systems while reducing downtimes in fast-paced production environments.

These examples illustrate merely a fraction of the potential reach of rotary union slip rings across industries and sectors. With constant technological advancements and innovative engineering, these devices will continue to make their mark on various applications, playing a crucial role in efficient machine operation and data transmission.

Rotary Union Slip Rings: Key Manufacturers and Models

In the continually evolving market of rotary union slip rings, several reputable manufacturers have established themselves by producing high-quality, reliable, and innovative devices. Notable among them are the following:

| No. | Manufacturer | Website |

|---|---|---|

| 1 | Hangzhou Grand Technology | https://www.grandslipring.com/ |

| 2 | Moog Inc. | https://www.moog.com/ |

| 3 | Stemmann-Technik | https://www.stemmann.com/en/home |

| 4 | Schleifring | https://www.schleifring.com/ |

Hangzhou Grand Technology

Hangzhou Grand Technology Co., Ltd. started as a special slip ring manufacturer in 2011. Grown into slip rings, rotary joints, and slip ring assembly experts of today with 6,000 square meter manufacture complex.

Obtained ISO9001, Rosh, CE, and GJB9001B certificates a number of slip rings, rotary joint patents, and proud of our products can meet military grade. Collaborated with universities, institutes, and renowned factories across Asia and Europe including Panasonic, SIEMENS, CSIC, SAMSUNG, HUAWEI, etc.

Moog Inc.

Moog is a leading supplier of high-performance slip rings for various industries, including aerospace. Among their offerings, Moog’s SR Series Slip Rings are designed for the demanding environments of helicopters, excelling in performance, reliability, and customization potential.

Stemmann-Technik

Stemmann-Technik, a part of the Conductix-Wampfler Group, offers a broad range of slip rings, including solutions for helicopters. Their Livietta Slip Ring Assemblies are designed explicitly for harsh and demanding environments in the aviation sector, providing reliable signal and power transmission.

Schleifring

Schleifring is a well-known manufacturer of electromechanical systems, including slip rings customized for various industries. Their Aircraft Slip Rings cater specifically to helicopters, offering robust performance, low wear, and high reliability to meet the challenges of aviation applications.

If you want to know more about other slip ring manufacturers, you can read Top 10 Slip Ring Manufacturers in China, Top 10 Slip Ring Manufacturers In the USA Market 2023, and Top 10 Slip Ring Industry Key Manufacturers 2023.

These key manufacturers and their popular models stand out in the rotary union slip rings market due to their commitment to quality, innovation, and reliability. By advancing current technologies and creating new solutions, these manufacturers continue to make a significant mark on the ever-growing industrial landscape.

Request more information about our Rotary Union Slip Rings by completing the form below.

Rotary Union Slip Rings Selection Guide: Factors to Consider

When selecting a rotary union slip ring for an application, there are several factors users should consider to ensure their chosen device meets the exact requirements of their equipment or system. The following crucial factors can guide users in making a knowledgeable selection:

Environmental Resistance

The specific environmental conditions in which the slip ring will operate are a major factor to consider. This includes temperature ranges, levels of dust or moisture, and corrosive environments. Users should look for models with adequate environmental resistance—whether that’s high-temperature tolerance, moisture or dust-proof sealing, or corrosion-resistant materials—to ensure reliable and consistent performance.

Signal Type and Capacity

The type and volume of signals to be transmitted—be it power, digital data, or analog signals—is another critical aspect. Some slip rings can transmit power signals only, while others can handle a combination of power and data signals. The user should ensure their slip ring of choice is capable of satisfying the signal demands of the application, in terms of both type and capacity.

Installation Space

A slip ring’s physical size is a crucial factor, especially in applications where space is limited. Users should consider the space available for the installation of the slip ring and opt for compact models where needed. However, the size should not compromise the necessary performance capabilities.

Cost and Lifespan

The cost of the slip ring is an obvious factor. While it may be tempting to opt for a cheaper solution, users need to ensure their chosen device offers long-term value in terms of durability and performance. It’s important to balance the upfront cost against the life expectancy of the slip ring, maintenance requirements, and potential downtime due to failures.

Manufacturer Reputation and Support

Reputation for quality and reliability from the manufacturer, along with warranty and support services, are other important factors. A reputable manufacturer with solid customer service and technical support can be as crucial as the product itself, especially when it comes to installation guidance and troubleshooting.

In conclusion, a careful assessment of specific applications and corresponding needs is key to determining the right type of rotary union slip ring. Keeping these factors in mind will help guide the selection process, ensuring the chosen device is well-aligned with application requirements and offers maximum performance, efficiency, and durability.

Rotary Union Slip Rings: Maintenance and Troubleshooting

Maintaining and troubleshooting rotary union slip rings are essential for ensuring their longevity and high-performance functionality. Here we’ll take a look at common issues and solutions, as well as preventative maintenance tips.

Common Issues and Solutions

Intermittent Signal Transmission

Intermittent signals are a common issue with rotary union slip rings. This could be due to worn-out or damaged brushes or a dirty surface on the rotating ring. Cleaning the ring surface with a soft cloth or gentle brush and replacing worn brushes as required can rectify this issue.

Increased Noise or Vibration

If there is an increased level of noise or vibration, it could signify mechanical issues such as loose parts or bearings. Inspecting the device for any loose components and ensuring all screws are properly tightened is a necessary step. If the bearings are damaged, a replacement may be required.

Data Loss or Degraded Signal Quality

Degraded signal quality or data loss can occur due to faulty wiring or poor connectivity. Checking and securing all connections, and troubleshooting the system to ensure all electrical connections are well-maintained should rectify this problem.

Preventative Maintenance Tips

Regular Cleaning

Regular cleaning of the rotary union slip rings is fundamental. Accumulation of dust or dirt can lead to electrical resistance and interference with signal transmission. Cleaning the rings with a soft cloth can prevent build-up.

Regular Inspection

The mechanical and electrical aspects of the slip ring should be inspected regularly. Checking for any signs of wear and tear, and loose components, and ensuring the continuity of electrical paths can identify potential problems early.

Timely Replacement of Components

Worn-out components, such as brushes, should be replaced timeously. Prolonged use of worn components can lead to damage to the ring surface and intermittent signal transmission.

Correct Usage and Operation

Ensuring the slip rings are used within the specified voltage, current, and speed ratings extends their service life. Overloading the slip rings can result in overheating and subsequent damage.

In conclusion, proper maintenance and optimum operational practices of rotary union slip rings can extend their product lifespan and ensure consistent, efficient operation. Regular troubleshooting practices can identify and rectify issues early, preventing potential failures and interruptions.

Rotary Union Slip Rings: Current Trends and Future Prospects

As technology continues to evolve across various sectors, so does the development of rotary union slip rings. The trend reflects a move towards more advanced and tailored solutions to cater to specific applications, enhancing both performance and efficiency. Here are some notable trends and prospects:

Wireless and Contactless Slip Rings

Wireless or contactless slip rings are a trending solution that eliminates the need for traditional brushes by employing electromagnetic waves or optical technology for power and data transmission. This contactless design offers benefits like reduced friction, decreased maintenance, and improved longevity, making these types of slip rings increasingly popular, especially in critical applications.

Integration of Advanced Sensors

The addition of sensors to the rotary union slip rings is becoming a standard industry practice. These sensors provide real-time monitoring of the device’s operational parameters, enabling predictive and preventive maintenance. This not only reduces the instances of unexpected failures but also extends the device’s lifespan.

Miniaturization

Driven by the demand in sectors where space constraint is a pivotal factor, miniaturized rotary union slip rings are emerging as a significant trend. Despite their compact size, these devices offer high-performance standards, particularly in terms of data transmission rates, making them suitable for advanced technologies such as robotic surgery, aerospace, and compact electronic devices.

Fiber Optic Rotary Joints

Fiber Optic Rotary Joints (FORJs) are garnering attention due to their capability to provide high-speed data transfer with minimal signal degradation. This makes them apt for telecommunications, broadcasting, and military applications, where the utmost signal quality is essential.

Future Prospects

The future of rotary union slip rings appears astoundingly promising. As more industries begin to harness the benefits of automated and digitalized operations, the need for efficient power and data transmission devices like rotary union slip rings will also grow.

There’s also increasing demand for highly customized solutions that cater to specific, challenging applications. This is expected to drive more innovations in product design and materials, thereby expanding the capabilities of rotary union slip rings.

In conclusion, ongoing technological advancements and emerging trends are gearing rotary union slip rings for exciting prospects. This adaptable and flexible technology will continue to evolve, providing increasingly efficient and robust solutions that meet the diverse needs of various industries.

Conclusion

Rotary union slip rings manifest a perfect blend of technological advancement and functional necessity. By bridging the gap between data transmission needs in stationary and rotating equipment, they stand as a symbol of industrial evolution and potential prospects.

See What We Can Do