Electrical systems often require the transfer of power or signals between stationary and rotating components. This is where rotating electrical connectors come into play. In this comprehensive guide, we will explore the ins and outs of rotating electrical connectors, covering their significance, workings, types, and selection process.

What are Rotating Electrical Connectors?

Definition

Rotating Electrical Connectors, also known as slip rings, electrical rotary joints, or electrical swivels, are electromechanical devices that allow the transmission of power, electrical signals, or data from a stationary to a rotating structure.

Function

The primary function of rotating electrical connectors is to maintain an electrical connection through a rotating interface, ensuring the continuous transfer of electricity or signals while one part of the system rotates. This capability is crucial in applications where a rotating component needs to be powered or communicate with a stationary part.

Components

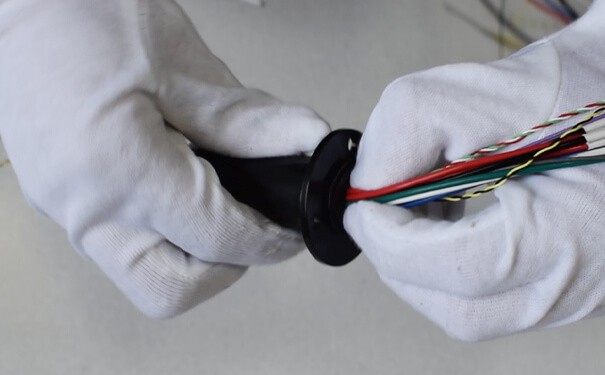

The structure of a rotating electrical connector is as intricate as its purpose. Its four primary components include the rotor, stator, conductive rings, and brushes. The rotor is the rotating part of the connector, while the stator stays stationary. Conductive rings, which are usually made of metal, are attached to the rotor and generally rotate along with it. Conversely, brushes – which can be made of various materials such as gold, silver, or copper – are affixed to the stator and stay stationary. The brushes constantly maintain contact with the spinning rings, forming an enduring electrical connection that allows for the signal or power to pass through.

Evolution

The journey of rotating electrical connectors has been marked by continuous innovation and technological advancement. In their simple early stages, these connectors were highly susceptible to wear and tear and could only accommodate limited power scopes. But with time, they underwent improvements, thanks to evolutions in material science and engineering approaches. Today, we see rotating electrical connectors made with advanced materials providing a larger bandwidth, catering to high power and data demands, and offering durability even in demanding environmental conditions. These connectors now come with sophisticated designs like capsule slip rings, through-bore slip rings, pancake slip rings, and more.

10 Benefits of Rotating Electrical Connectors

Rotating Electrical Connectors offer numerous benefits across a range of applications. Here are ten key benefits:

The Working Principle of Rotating Electrical Connectors

Working Mechanism

At the heart of the working principle of rotating electrical connectors is the task of maintaining electrical conductivity between the stationary and rotating parts of a system. The rotor, connected to the rotating part of the system, is fitted with conductive tracks or rings. At the same time, brushes – set to the stationary part (also known as stator) – slide or rub against these conductive rings. Despite their relative motion, this continual contact between the brushes and conductive rings ensures that the electric current or signal is continuously transferred from the moving to the stationary part, or vice versa. Simultaneously, the connector design employs strategies to keep the friction that occurs between the brushes and conductive rings minimal. This helps in preventing rapid wear and tear and maintaining the longevity of the connector.

Power Transmission Process

The process of power transmission in rotating electrical connectors begins at the source, attached to the stationary part of the connector. The brushes, also connected to the stationary part, play a crucial role here. From the source, the electrical power enters the brushes, which are maintained in constant contact with the conductive tracks or rings placed on the rotor. As the rotor spins, the electrical power is transferred via the rotating conductive tracks to the rotating part of the system. This mechanism allows for the free transmission of electrical power between components, regardless of their motion relative to each other. Component rotation and power transmission can thus occur simultaneously without interference.

Types of Rotating Electrical Connectors

- Rotary Electrical Connector: This type of connector is designed to be used with a rotary motion. It features a flexible wire or cable that is connected to a rotary joint. The rotary joint allows the electrical connection to rotate while maintaining a secure connection.

- Rotating Connector: This type of connector is designed to rotate in one direction, allowing it to be used with a variety of applications. It features a flexible wire or cable that is connected to a rotating connector.

- Slip Ring Rotating Connector: This type of connector is designed to be used with a rotary motion and features a slip ring that allows the electrical connection to rotate without losing its connection.

- Rotating Cable Connector: This type of connector is designed to be used with a rotary motion and features a flexible wire or cable that is connected to a rotary connector.

- Swivel Wire Connector: This type of connector is designed to be used with a rotary motion and features a swivel wire or cable that is connected to a rotating connector.

- Rotary Joint Electrical Connector: This type of connector is designed to be used with a rotary motion and features a rotary joint that allows the electrical connection to rotate while maintaining a secure connection.

- Rotating Power Connector: This type of connector is designed to be used with a rotary motion and features a power cable that is connected to a rotating connector.

- Rota Connector: This type of connector is designed to be used with a rotary motion and features a flexible wire or cable that is connected to a rotary joint.

- Slip Ring Rotary Joint Electrical Connector: This type of connector is designed to be used with a rotary motion and features a slip ring that allows the electrical connection to rotate without losing its connection.

- Rotating Electrical Connector Slip Ring: This type of connector is designed to be used with a rotary motion and features a slip ring that allows the electrical connection to rotate without losing its connection.

- Rotating Electrical Connectors: Designed to handle high-frequency signals with minimal interference.

- Hydraulic Slip Rings: Combine electrical slip rings with fluid rotary joints to transmit power and hydraulic fluid.

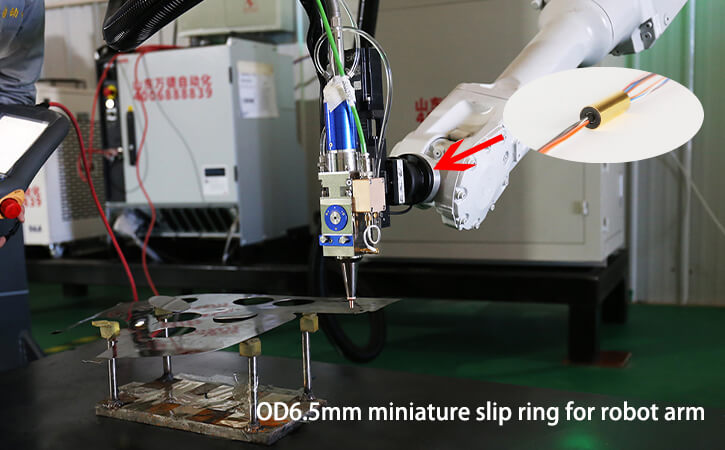

- Robotic Slip Rings: Designed to handle the dynamic movements of robotic joints.

- High-Temperature Slip Rings: Capable of withstanding high temperatures without performance degradation.

Applications of Rotating Electrical Connectors

The versatility and functionality of rotating electrical connectors make them the go-to solution in a host of applications. They play a significant role in CCTV systems, enabling cameras to continuously pan without the hindrance of cords. Wind turbines are another critical application, where these connectors help transmit power and signals from the turbine’s rotating blades to the stationary parts. In medical fields, they facilitate the rotation of CT scans, making precise imaging possible. In addition, spinning electrical connectors are heavily used in radar systems, robotics, and even amusement park rides, pointing to their vast capability across varied industries.

Rotating Electrical Connectors, also known as slip rings or electrical swivels, have a wide range of applications across various industries. Here are some key applications:

- Function: Transmit electrical power and control signals from the stationary base to the rotating blades.

- Benefit: Ensures continuous power supply and signal transmission for efficient energy production.

2. Robotics

- Function: Enable continuous rotation of robotic joints while transmitting power and control signals.

- Benefit: Facilitates the seamless operation of robots, especially in manufacturing and automation processes.

3. Medical Equipment

- Function: Used in devices like CT scanners and MRI machines to allow continuous data transfer as the scanner rotates.

- Benefit: Provides uninterrupted operation and high-quality imaging in medical diagnostics.

4. Aerospace

- Function: Transfer signals and power in rotating parts of aircraft and spacecraft, such as radar systems and satellite antennas.

- Benefit: Ensures reliable communication and power supply in critical aerospace applications.

5. Industrial Machinery

- Function: Maintain power and signal connectivity in rotating equipment, such as packaging machines, cranes, and rotary tables.

- Benefit: Enhances the efficiency and functionality of industrial machinery by allowing continuous operation.

6. Marine Applications

- Function: Used in rotating parts of marine vessels, such as propulsion systems and radar units.

- Benefit: Ensures the reliable operation of essential systems in harsh marine environments.

7. Defense and Military

- Function: Integrated into military equipment like tanks, radar systems, and weaponry for power and data transmission.

- Benefit: Provides robust and reliable performance in critical and demanding defense applications.

8. Telecommunications

- Function: Used in communication systems, such as rotating antennas and satellite dishes.

- Benefit: Facilitates continuous signal transmission and enhances the reliability of communication networks.

9. Entertainment and Theatrical Equipment

- Function: Integrated into rotating stages, lighting rigs, and other equipment in theaters and concert venues.

- Benefit: Allows for dynamic and uninterrupted performances by enabling the smooth rotation of stage equipment.

10. Automotive

- Function: Used in rotating parts of vehicles, such as steering wheels with integrated controls and sensors.

- Benefit: Enhances vehicle functionality and driver experience by enabling seamless integration of control systems.

11. Renewable Energy

- Function: Employed in solar trackers to maintain the optimal orientation of solar panels.

- Benefit: Maximizes energy capture by ensuring continuous adjustment of solar panels to follow the sun.

These applications highlight the versatility and importance of rotating electrical connectors in facilitating reliable and efficient operation across various industries.

How to Choose The Rotating Electrical Connectors

Choosing the right rotating electrical connector (slip ring) involves considering several factors to ensure optimal performance, reliability, and longevity for your specific application. Here are key steps and considerations:

1. Identify Application Requirements

- Type of Signals: Determine the types of signals to be transmitted (power, data, control signals, fiber optics).

- Number of Circuits: Count the number of independent circuits needed.

- Current and Voltage Requirements: Assess the electrical power requirements, including the current and voltage ratings.

2. Mechanical Considerations

- Rotational Speed: Specify the maximum rotational speed (RPM) the connector will operate at.

- Space Constraints: Consider the physical dimensions and space available for the slip ring installation.

- Mounting Configuration: Identify the mounting style (capsule, through-bore, pancake) that best fits your system design.

3. Environmental Conditions

- Temperature Range: Ensure the slip ring can operate within the expected temperature range.

- Protection Rating: Determine the level of protection needed against dust, moisture, and other environmental factors (IP rating).

- Durability: Consider exposure to vibration, shock, and other mechanical stresses.

4. Signal Requirements

- Signal Integrity: Ensure the slip ring maintains signal integrity with minimal electrical noise.

- Bandwidth and Data Rate: Check if the slip ring can handle the required data rates, especially for high-frequency or fiber optic signals.

5. Material and Construction

- Contact Materials: Look for high-quality contact materials (e.g., gold, silver) to reduce wear and enhance conductivity.

- Housing Materials: Choose durable housing materials that can withstand environmental conditions and mechanical stresses.

6. Additional Features

- Hybrid Capabilities: If needed, select slip rings that can transmit multiple types of signals (e.g., electrical, fiber optic) in one unit.

- Maintenance Requirements: Consider the ease of maintenance and the expected lifespan of the slip ring.

- Customization: Determine if custom slip rings are needed for specific application requirements.

7. Vendor and Quality Considerations

- Reputation and Experience: Choose a reputable manufacturer with experience in producing high-quality slip rings.

- Compliance and Certifications: Ensure the slip ring meets industry standards and certifications (e.g., ISO, RoHS).

- Customer Support: Look for manufacturers that provide excellent customer support and after-sales service.

Example Consideration Table

| Criteria | Considerations | Importance |

|---|---|---|

| Application Requirements | Signal type, number of circuits | High |

| Mechanical | Rotational speed, space constraints | High |

| Environmental | Temperature, IP rating | High |

| Signal Requirements | Signal integrity, data rate | Medium |

| Material & Construction | Contact and housing materials | Medium |

| Additional Features | Hybrid capabilities, maintenance | Low |

| Vendor & Quality | Reputation, certifications, support | High |

Step-by-Step Selection Process

- Define Application Needs: Start with a clear understanding of what the slip ring will be used for, including all electrical and mechanical requirements.

- Research Options: Look for slip rings that match your initial criteria from reputable suppliers.

- Compare Specifications: Review the detailed specifications of potential slip rings to ensure they meet all your requirements.

- Evaluate Environmental Suitability: Confirm that the chosen slip ring can withstand the operating environment.

- Check for Additional Features: Consider any extra features or customizations that might be beneficial.

- Vendor Assessment: Choose a supplier based on product quality, reputation, and support services.

- Testing and Validation: Once selected, conduct testing under real-world conditions to validate the slip ring’s performance.

By carefully considering these factors and following a systematic selection process, you can choose the right rotating electrical connector for your specific application, ensuring reliable performance and longevity.

Determining the Right Rotating Electrical Connector for Your Needs

User Requirements

Identifying the right rotating electrical connector is primarily dictated by the specific user requirements. Start by understanding the purpose the connector needs to fill: Is it to transmit signals, power, or both? How large is the power or data bandwidth? Answering such key questions will help in identifying which type of connector is most suitable. The dimensions of the connector are another crucial factor. Limitations in device size and available installation space will influence the choice, potentially steering you towards capsule slip rings or miniature slip rings over larger types. Lastly, consider the nature and speed of rotation, alongside your desired lifespan for the connector. High-speed systems or lengthy service life requirements may necessitate premium materials or designs to withstand such conditions.

Environment and Load Conditions

The environmental constraints and load conditions in which your system operates have a significant bearing on the choice of a rotating electrical connector. For instance, systems operating in harsh conditions, such as high temperatures, high humidity, or heavy dust, will require connectors that are designed to withstand these extremes without compromising performance. If the connector will be subjected to heavy mechanical loads or high electrical loads, durability and robustness become primary considerations. Understanding these factors can guide the choice towards, for instance, a through-bore slip ring for the flexibility of additional load accommodation or a high-frequency slip ring for systems with high electrical loads. Being cognizant of these factors ensures that the chosen connector is well-suited to deliver optimal performance in the intended operating conditions.

Where to Buy a Rotating Electrical Connector

Reliable Vendors

Finding a reliable vendor is the first step in acquiring a quality rotating electrical connector. There are numerous trusted manufacturers and stockiest worldwide known for their quality and credibility. Some of these include Moog Inc., Schleifring Systems Ltd., MERSEN, and UEA (United Equipment Accessories). They offer a wide range of rotating electrical connectors suited for various applications. Additionally, online platforms like Amazon, Alibaba, and Digi-Key present an array of offerings from different manufacturers, providing you with numerous choices and competitive pricing.

Purchase Considerations

When purchasing rotating electrical connectors, several factors need to be taken into account. First, ensure the type of connector matches your specific needs and application requirements. Verify that the connector can handle the expected power or signal bandwidth, and speed of rotation, and is compatible with the installation space available. Second, factor the environment the connector will be operating in if it’s a harsh environment, choose connectors designed to withstand such extremes. Additionally, consider the product’s warranty terms and customer support provided by the vendor. Don’t forget to look at the reviews and reputation of the vendor – these can offer invaluable insights into the product and after-sale services.

Customization

In many scenarios, off-the-shelf solutions may not be ideal. You might need connectors tailored to suit specific needs. Vendors like Moog Inc. and UEA offer customized rotating electrical connector solutions to meet unique specifications. Customization can take into consideration aspects such as connector size, the number of circuits, wiring arrangements, specific material use, or special additions such as pneumatic or hydraulic lines. While customized connectors might come at a premium price, they can ensure superior performance and a better fit in unconventional scenarios.

Installation and Maintenance of Rotating Electrical Connectors

Installation and maintenance of rotating electrical connectors are key to ensuring optimal performance and longevity.

Installation:

Proper installation begins with a thorough understanding of the manufacturer’s instructions. These guidelines will precisely detail the steps and precautions needed to correctly install the connector. Common specifications include:

- Ensuring correct orientation: Some connectors may specify a particular rotation direction or installation orientation. This is crucial to maintain electrical integrity and minimize wear and tear.

- Properly connecting wires: Connections need to be made carefully to avoid loose contacts, which may compromise conductivity or cause sparking.

- Not exceeding the load: Continuous power or signal load should not exceed the connector’s specifications. Overloading can lead to severe damage and reduced lifespan.

Maintenance:

Regular maintenance is needed to sustain performance and prolong the lifespan of rotating electrical connectors. Here are some maintenance practices:

- Regular Cleaning: Dust, debris, or oxidation can compromise conductivity. Regularly cleaning the connector surfaces helps maintain optimal power or signal transmission.

- Inspection and Replacement of Worn Parts: Regular inspection of the connector, especially the worn parts like brushes, should be carried out. Any severe wear and tear necessitate timely replacement.

- Lubrication: Where specified by the manufacturer, suitable lubrication can help reduce friction and heat generated due to the rotation, thereby extending the life of the connector.

Periodical checks and prompt servicing help mitigate unforeseen breakdowns, ensuring that the rotating electrical connector performs efficiently over the course of its service life. It’s critical to keep in mind, however, that not all connectors can be handled the same way. Always follow the manufacturer’s specific instructions for both installation and maintenance.

The Future of Rotating Electrical Connectors

As technology continues to evolve, the field of rotating electrical connectors is expected to experience several trends, innovations, and developments to support emerging applications and address challenges. Here are some promising directions for the future of rotating electrical connectors:

Miniaturization:

With the increasing need to fit complex systems into smaller devices, the miniaturization of rotating electrical connectors will continue to be a dominant trend. This shift will demand high-precision manufacturing processes and advanced materials that enable reliable efficiency while maintaining compact sizes.

Environmentally-Friendly and Sustainable Designs:

As the world moves towards embracing sustainable and eco-friendly practices, future connectors may incorporate new materials and designs to minimize environmental impact. This could include materials that are easily recyclable, biodegradable, or have a reduced carbon footprint.

Higher Data Rates:

With the ever-increasing demand for high-speed data transmission, such as in 5G networks, radar systems, or high-resolution cameras, improvements in rotating electrical connectors will focus on supporting higher bandwidths without compromising performance.

Wireless Technology:

One potential development pertains to the integration of wireless technology in rotating connectors. This shift could potentially eliminate physical wear and tear problems, thereby increasing the efficiency and lifespan of connectors that incorporate wireless signal transfer technology.

Improved Durability:

As applications push the limits of their operating environments, such as extreme temperature ranges or the presence of corrosive substances, connectors will need to exhibit increased durability. This will drive the adoption of advanced materials and manufacturing processes to improve wear resistance and lifecycle performance.

Integration of Smart Features:

Digitalization and Industry 4.0 are shaping how we interact with systems. New connector developments may incorporate smart features like self-diagnosing and monitoring capabilities, providing valuable real-time data on the connector’s performance and aiding predictive maintenance.

These trends underscore how rotating electrical connectors will need to evolve to meet the demands of increasingly sophisticated applications, ranging from robotics and aerospace to medical equipment and beyond. As the industry adapts, we can expect exciting innovations that will enable transformative advancements in countless domains.

Conclusion

Rotating electrical connectors are essential for various applications that require transmitting electrical signals or power between stationary and rotating parts. Understanding their functions, benefits, and types will help you make informed decisions when selecting the right connector for your needs, ensuring the safe and efficient operation of your electrical systems.

Seeking High-Performance Rotating Joints? Get in Touch Today!

FAQs about Rotating Electrical Connectors

To help address common questions consumers have about rotating electrical connectors, we’ve compiled and answered some of the most common queries.

Q: What is the typical lifespan of a rotating electrical connector?

A: The lifespan of a rotating electrical connector depends on various factors including the connector type, the quality of materials used, the environment in which it operates, and its maintenance regime. With proper care and under optimal conditions, these connectors can last several years. Always follow manufacturer guidelines for your specific connector to ensure maximum lifespan.

Q: Can I use rotating electrical connectors in harsh environments?

A: Yes, many rotating electrical connectors are designed to withstand harsh environments such as high temperatures, extreme humidity, and dusty conditions. You should choose a connector specifically engineered for harsh conditions, usually referred to as “ruggedized” or “industrial-grade” connectors. Ensure that the connector’s specifications match the environment it will be operating in.

Q: Are rotating electrical connectors suitable for high-speed applications?

A: Yes, some rotating electrical connectors are designed for high-speed applications. These connectors, typically made with premium materials and advanced designs, allow the safe and efficient transmission of signals or power at high rotational speeds. It’s crucial to choose the right connector that can handle the desired speed of your system.

Q: What are the most common applications of rotating electrical connectors?

A: Rotating electrical connectors can be found in a wide variety of applications such as robotics, wind turbines, camera systems, medical equipment, radar systems, aerospace, and defense systems, to name just a few. They are used in any system that requires power or signal transfer between rotating and stationary components.

Q: Can I customize a rotating electrical connector to fit my specific requirements?

A: Yes, many manufacturers of rotating electrical connectors offer customizable solutions to cater to unique user requirements. These customizations can include alterations in the connector size, the number of circuits, and material specifications, as well as the incorporation of additional features like pneumatic or hydraulic passages.

See What We Can Do