Our article opens the door to the world of single-channel slip rings, shedding light on their basic principles, applications, advantages, and user concerns. We also delve into the selection criteria for users and illuminate the future trends and innovations in this field.

Introduction to Single-Channel Slip Ring

In the realm of mechanical design and electrical engineering, the single-channel slip ring plays a pivotal role, albeit often unnoticed by the layperson. A single-channel slip ring is a precise mechanical device designed to enable power, signal, or data transmission from a stationary part of a machine to its rotating component, all within a single, streamlined electrical circuit. The term “single-channel” denotes its capacity to facilitate a solitary connection for either power, signal, or data transfer, distinguishing it from its multi-channel counterparts that manage multiple connections simultaneously.

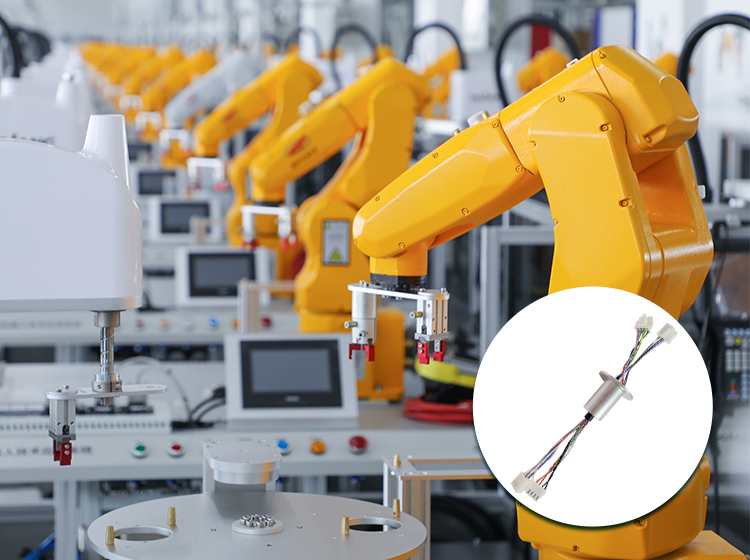

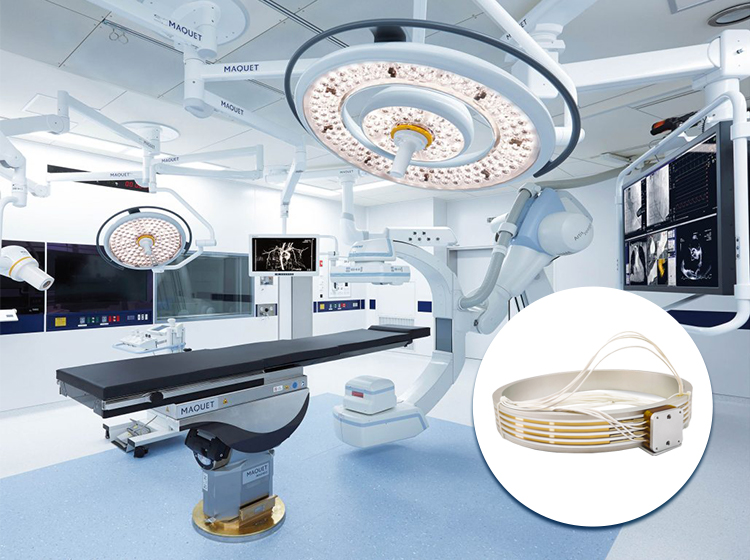

The significance of single-channel slip rings extends far beyond their basic function. These devices are integral to the seamless operation of a vast array of machinery and equipment, serving as the backbone for continuous and reliable rotational movements. For instance, in the industrial sector, they are indispensable in the automation of manufacturing processes, playing a crucial role in the functionality of robotic arms, packaging machinery, and turntables. Their application, however, is not confined to industry alone. In the medical field, single-channel slip rings contribute significantly to the advancement of diagnostics and patient care through their deployment in medical imaging devices, enabling the rotation required for comprehensive scanning without compromising the transfer of critical data. Furthermore, their utility spans aerospace and military applications where dependable communication between stationary and rotating platforms is paramount, as well as in consumer electronics, enhancing the user experience in devices where rotational motion is key.

This broad spectrum of applications underscores the versatility and importance of single-channel slip rings. Their ability to ensure continuous power supply and data transmission across rotating interfaces not only boosts efficiency but also enables innovation across various fields. The seamless integration and reliable performance of single-channel slip rings facilitate the development of more advanced, efficient, and reliable machinery and systems across diverse industries, marking their critical role in the modern world’s technological advancement.

Basic Principles Behind Single-Channel Slip Rings

Understanding the foundational principles behind single-channel slip rings necessitates delving into the broader category of mechanical devices known as slip rings. Slip rings are electromechanical devices that facilitate the transmission of power and electrical signals between a stationary structure and a rotating component. They serve as the critical bridge that eliminates the limitations imposed by fixed wiring, allowing for uninterrupted rotation and functionality. In essence, slip rings are the unsung heroes in the background, ensuring that devices and machinery requiring rotational movement can operate without hitches or interruptions in power and data flow.

The operation of a single-channel slip ring centers around its specialized design to manage a singular connection for transmitting power, signals, or data. The magic of its functionality unfolds through its core working principle – the establishment of a continuous conductive path between the stationary and rotating parts of a machine. This is achieved when the conductive ring, mounted on the rotating shaft, aligns perfectly with the brush, or contact, fixed on the stationary part. As the shaft turns, the conductive ring maintains a constant electrical connection with the brush, thereby ensuring a seamless flow of electricity or data along the single channel, despite the rotational movement.

The key components of a single-channel slip ring play distinct roles in this process:

- The Conductive Ring: This is the heart of the slip ring, a metal ring that rotates with the shaft of the machine. Its primary function is to carry the electrical current or signal from the stationary brush to the rotating part of the device.

- The Brush: Typically made of a soft conductive material like graphite or copper alloys, the brush is a stationary component that maintains contact with the conductive ring. It is through this contact point that the electrical current or data enters the conductive ring from the stationary part of the system.

- The Housing: Enclosing the conductive ring and the brush is the housing, a protective shell that serves multiple purposes. It not only safeguards the internal components from debris, dust, and potential damage but also provides structural support and insulates the electrical components, preventing unintended electrical paths.

The coherent interplay between these components ensures that single-channel slip rings can reliably transmit electrical power or signals in devices requiring rotation. From industrial machinery to medical equipment, the practicality and reliability of single-channel slip rings stem from their fundamental workings, illustrating the ingenuity of integrating simple components to solve complex mechanical challenges.

Single-Channel Slip Ring: Types and Variations

Despite the collective nomenclature of ‘single-channel slip ring,’ this category of mechanical devices is far from monolithic. There are several variants of single-channel slip rings, all tailored to different contexts and tasks. These variations are typically distinguished by the materials used, the size of the device, its construction, and the specific purpose it serves.

The material used in manufacturing the single-channel slip rings plays a crucial role in their durability, resilience, and performance. Some slip rings employ metal brushes and rings for high conductivity and durability, while others may use graphite or composite brushes to reduce friction, ensuring longer life. The choice of materials ultimately depends on the type of current the device must handle, the required lifespan, and the operating environment.

Size is another differing factor among single-channel slip rings. In compact mechanical systems like certain consumer electronics or medical devices, miniaturized slip rings are used due to restricted space availability. Conversely, in larger machinery, such as industrial equipment, larger slip rings are employed, given the potential need for higher power transmission or robustness.

The construction of single-channel slip rings varies as well, with design options ranging from pancake models, ideal for situations where axial length needs to be minimized, to capsule models, perfect for compact applications. Further, there are through-hole models for applications requiring the slip ring to be mounted around an axle or shaft, and modular designs that allow for easy integration into existing systems with predefined configurations.

Single-channel slip rings can be customized beyond these standard types and variations to meet the unique requirements of an application. Whether the need is for a slip ring with high speed, high current capacity, or the ability to operate in extreme environmental conditions, manufacturers can customize the design, material, and construction to align with its intended use.

The wide array of types and variations in single-channel slip rings demonstrates the fine balance between universal functionality and specific adaptation. It mirrors the evolution of these essential devices, from one-size-fits-all to tailor-made, driven by the ever-evolving landscape of technology and industry requirements. As our technological capabilities continue to expand, so too will the versatility and adaptability of the single-channel slip ring, forever breathing life into the heart of rotating machinery.

Single-Channel Slip Ring: Main Applications

The omnipresence of single-channel slip rings across multiple industries underlines their versatility and critical role in driving the smooth operation of various mechanisms. Given their unique ability to facilitate uninterrupted power, signals, or data transfer from stationary to rotating parts, these devices find significant use in myriad applications worldwide.

Industrial Uses

Within the industrial sector, single-channel slip rings find extensive applications:

- Robotics: Robots, especially those with rotational components like robotic arms, heavily rely on slip rings. The rotational motion of these parts demands seamless power transmission or data communication between the stationary and moving parts. Single-channel slip rings enable this rotational freedom while maintaining continuous electrical contact.

- Packaging Machinery: Machines for packaging, such as those used for wrapping, labeling, or bagging, often require rotational movements. Single-channel slip rings come into play here, ensuring reliable transmission of power or signals during these rotating operations.

- Turntables: From exhibition turntables to industrial rotary tables, the unimpeded rotation fundamental to their very function is facilitated by single-channel slip rings, making continuous rotations a reality without any tangling or limits of cables.

Medical Applications

In the medical field, single-channel slip rings bring far-reaching benefits:

- Medical Imaging Devices: Devices such as CT scanners necessitate both rotation and the transmission of high-quality, real-time imaging data. Single-channel slip rings are integral to these machines’ operation, transmitting data from the rotating scanner to the stationary computer system while allowing the seamless rotation of the scanner around the patient.

Aerospace and Military Applications

Both the aerospace and military sectors have stringent demands for reliable, high-quality data and signal transmission—single-channel slip rings cater to these needs:

- They are used in radar systems, satellite contacts, missile launchers, and turbojet engines, where they perform crucial functions in maintaining communication, controlling movement, and sharing real-time data from rotating elements of these systems.

Consumer Electronics

Perhaps one of the most relatable realms where single-channel slip rings exist is consumer electronics, where they display their versatility:

- From the internal antenna of a mobile phone or tablet, which must rotate freely to maintain signal reception, to the wind-directing mechanism of an air conditioner that moves back and forth, single-channel slip rings are a silent provider. They even play a role in enabling the 360° rotation of your LED revolving stage lights or the turntable in your vintage record player.

Regardless of the industry or application, the core function of single-channel slip rings remains the same: to enable a smooth, uninterrupted connection during rotation. Their varied uses across different domains are a testament to their adaptability and fundamental role in facilitating operational efficiency in rotating mechanisms.

Advantages of Single-Channel Slip Rings

The inception of single-channel slip rings into the realm of mechanical and electrical engineering has marked a revolution, particularly in applications requiring a seamless and uninterrupted flow of power or data between rotating and stationary parts. The design and operational benefits these devices offer translate into significant advantages across various industries and applications.

Compact Design and Its Benefits

The hallmark of single-channel slip rings lies in their compactness. Their small footprint makes them an ideal choice for applications where space is at a premium. This compact design is not merely about saving space; it incorporates the ability to perform under constrained conditions without sacrificing performance. For instance, in medical devices such as compact CT scanners or in consumer electronics where space is limited, the compactness of single-channel slip rings allows them to fit snugly, making sophisticated rotational functions possible in tight spaces. This miniaturization does not compromise their functionality but rather enhances the design flexibility of the devices they are part of.

Reliability in Continuous Rotation Applications

One of the most valued features of single-channel slip rings is their reliability, especially in applications involving continuous or repetitive rotation. These devices maintain a consistent electrical connection between stationary and rotating parts, ensuring that data or power transmission does not suffer due to the movement. In industrial automation, for instance, where machinery operates round the clock, the reliability of single-channel slip rings ensures that there is no interruption in productivity. This uninterrupted performance is crucial in sectors like aerospace and defense, where the reliable performance of slip rings in systems such as radar and communication devices can be mission-critical.

Ease of Integration into Various Systems

Another significant advantage is their ease of integration. Single-channel slip rings can be easily incorporated into existing systems without the need for extensive redesign or modification. This plug-and-play capability means industries can upgrade their systems with rotational functionalities without significant downtime or investment. Whether it’s upgrading existing machinery in a manufacturing line or integrating it into the design of new consumer electronics, the straightforward integration of slip rings accelerates innovation and deployment.

Cost-Effectiveness for Single Electrical Circuits

For applications necessitating the transmission of power or data along a single circuit, single-channel slip rings present a cost-effective solution. Their design, tailored for simplicity and efficiency, means they are generally less expensive than their multi-channel counterparts. This cost efficiency makes them particularly attractive for projects and products where budget constraints are a consideration, without having to compromise on the essential functionality that slip rings provide. This advantage is a boon for startups and small-to-medium enterprises in sectors from consumer electronics to industrial manufacturing, enabling them to incorporate sophisticated rotating capabilities into their products without significantly inflating costs.

In summary, the advent and adoption of single-channel slip rings underscore a leap toward greater efficiency, reliability, and cost-effectiveness in the design and operation of systems requiring rotational motion. Their compact design, reliability, ease of integration, and cost efficiency not only solve a variety of engineering challenges but also open avenues for innovation across a spectrum of applications.

Single-Channel Slip Ring: Key Concerns and Challenges

While single-channel slip rings wield numerous advantages, they are full of challenges. These devices, like any other mechanical component, are subject to issues that can affect their performance and lifespan. Addressing these concerns is paramount for maintaining their efficacy in diverse applications.

Wear and Tear Over Time

One of the primary challenges associated with single-channel slip rings is the inevitable wear and tear they experience over their operational life. Repeated physical contact in the form of rotational friction between brushes and rings induces gradual degradation. This can manifest as eroded contact surfaces, leading to inefficient power or signal transmission and eventual device failure. In industrial settings, where machinery may operate continuously, this issue is exacerbated, demanding the use of more durable materials and designs that can withstand long operational hours and high rotational speeds.

Electrical Noise and Its Impact on Signal Integrity

Electrical noise poses substantial challenges to the efficacy of single-channel slip rings. The rotating interface is inherently prone to generating electrical noise, particularly in less-than-ideal contact conditions or when contaminated with conductive debris. This noise can severely compromise the integrity of the signals being transmitted, which is a critical issue in applications that require the precise conveyance of data. For delicate operations, such as those in the field of medical imaging or aerospace communication systems, even minor signal degradation can have significant consequences ranging from reduced image quality to impaired navigation and communication functions.

Maintenance Requirements

Maintenance is a critical factor in the long-term functioning of single-channel slip rings. As these devices are subject to wear and may accumulate debris, they require regular inspection and cleaning to ensure optimal performance. Maintenance requirements can represent a logistical challenge, especially if the slip rings are located within complex or compact systems where accessibility is limited. In such cases, maintenance can be time-consuming and costly, impacting the overall downtime and productivity of the system they are part of.

Environmental Factors Affecting Performance

Environmental factors are also among the key concerns that can affect the performance of single-channel slip rings. Dust, moisture, and other contaminating elements can intrude on the contact surfaces, leading to poor conductance, increased wear, and eventually, the failure of the device. Such contaminants can be particularly problematic in outdoor applications, such as in wind turbines, or in settings where cleanliness is hard to maintain, such as manufacturing facilities. Designing slip rings with adequate sealing and protective measures is essential to mitigate these environmental challenges, but such measures may add to the complexity and cost of the device.

To summarize, while single-channel slip rings are integral to the functionality of numerous systems, their associated concerns and challenges, such as wear and tear, electrical noise, maintenance demands, and environmental susceptibility, necessitate thoughtful design considerations, regular upkeep, and sometimes more sophisticated engineering solutions, to ensure they continue to perform effectively within their specific application contexts.

Single-Channel Slip Ring: Selection Criteria for Users

Choosing the right single-channel slip ring is a critical decision that can significantly impact the efficiency and reliability of a system. When embarking on this selection process, it’s essential to understand that a slip ring must be tailored not just to the task at hand, but to the environment it operates in, and the specific demands of the application. Here are key factors to guide users in making an informed choice:

Application-Specific Requirements

The intended application of the slip ring dictates the primary considerations for its selection. It’s essential to assess whether the device is meant for power transmission, signal transmission, or a combination of both. For instance, applications in the realm of robotics or rotating cameras may prioritize signal integrity, necessitating slip rings with minimal electrical noise. Meanwhile, heavy industrial applications might demand models that can handle higher current loads. The torque requirements and the expected number of rotations per minute (RPM) are also crucial; applications with high RPMs require slip rings with low friction and wear rates. Understanding these nuances ensures the selected slip ring aligns with the operational exigencies of the application.

Electrical and Mechanical Specifications

The electrical requirements, including the voltage and current rating, are fundamental to selecting an appropriate slip ring. A mismatch here can lead to inadequate performance or even device failure. Equally crucial are the mechanical specifications; dimensions, mounting type, and housing material must be compatible with the application environment. For example, a slip ring intended for a compact consumer gadget needs not just to fit spatially but also to complement the gadget’s aesthetic and durability requirements. Likewise, slip rings for industrial applications must have robust constructions to withstand the rigors of their operating environments.

Environmental Considerations

The environment in which the slip ring will operate cannot be overlooked. Factors such as exposure to dust, moisture, corrosive substances, or extreme temperatures significantly influence the choice of slip ring. For outdoor or harsh industrial settings, slip rings with high ingress protection (IP) ratings are essential to protect against dust and water ingress. Similarly, applications involving exposure to chemicals or corrosive substances may require slip rings made of specific materials that offer better resistance. These considerations ensure the slip ring remains functional and reliable under the intended environmental conditions.

Manufacturer Reputation and Support Services

Finally, the choice of manufacturer plays a pivotal role in securing a reliable slip ring. It’s advisable to opt for manufacturers with a solid reputation in the industry, known for producing quality products and providing excellent support services. This includes after-sales support, availability of spare parts, and the provision of comprehensive documentation for installation, operation, and maintenance. Furthermore, manufacturers that offer customization options can be invaluable for applications with unique or demanding specifications. In essence, a manufacturer’s credibility and the support offered can be just as critical as the technical specifications of the slip ring itself.

In summarizing these criteria, it becomes evident that selecting a single-channel slip ring is a multifaceted decision process that demands careful consideration of application requirements, technical specifications, environmental resilience, and manufacturer reliability. By meticulously evaluating these factors, users can ensure the selection of a slip ring that meets their needs and enhances the performance and reliability of their systems.

Single-Channel Slip Ring: Future Trends and Innovations

The future of single-channel slip rings is shaped by the dynamic interplay of evolving technologies, emerging market demands, and innovative material science. As industries evolve, slip ring designs and functionalities are witnessing transformative changes and trends, which present a new range of possibilities and challenges.

Advances in Materials and Technology Enhance Slip Ring Performance

Material science plays a pivotal role in the enhancement of slip ring performance. The industry is seeing the introduction of advanced materials such as composites and nano-material coatings designed to minimize wear and reduce maintenance needs. These materials can significantly increase the lifespan of slip rings even under high-speed rotations and demanding applications. In addition, technological advancements in surface engineering are leading to improved electrical contacts that offer higher conductivity and resistance to environmental factors.

Moreover, the incorporation of smart technologies, like embedded sensors, is leading slip rings toward predictive maintenance capabilities. These sensors can detect and communicate wear levels or performance anomalies before they lead to failure. This move towards smarter slip rings aligns with the broader shifts in industrial maintenance from reactive to proactive strategies.

Growing Applications in Emerging Industries

Single-channel slip rings are branching out into new and innovative industries, driven by advancements in robotics, renewable energies, and space exploration, to name a few. In the field of robotics, slip rings enable the continuous transmission of power and data in robotic arms and drones, facilitating 360-degree rotation without cable twisting. Similarly, in the renewable energy sector, particularly in wind turbines, slip rings play a crucial role in ensuring efficient power and data transmission from the nacelle to the stationary parts of the structure.

Space exploration presents another frontier, with slip rings being adapted to conditions of vacuum and extreme temperatures. These adaptations involve changes not just to materials but also to design, reflecting the specialized needs of spacecraft and satellite systems. With the uptick in commercial space ventures, the demand for robust and reliable slip ring technology is set to escalate.

Connectivity and the Role of Slip Rings in the Integration of IoT (Internet of Things)

The integration of IoT into industrial and consumer applications is ushering in an era where connectivity is key. This connectivity is not limited to static systems but extends to rotating platforms where slip rings are indispensable. As IoT devices require continuous data transmission, slip rings play an essential role in enabling these devices within moving components to communicate with the broader network.

The future of IoT involves a seamless blend of data and operational technology, where slip rings could evolve to facilitate the integration of sensors, control systems, and actuators in a connected ecosystem. These advancements imply a potential for slip rings to move beyond their traditional roles, becoming integral components in the architecture of smart factories, intelligent transportation systems, and autonomous vehicles.

In conclusion, the outlook for single-channel slip rings is one marked by rapid advancements in material sciences, widening applications across nascent industries, and the critical role in realizing the potential of IoT. These trends and innovations propel slip rings from a merely functional component to a keystone in the next generation of interconnected and intelligent systems.

Conclusion

The humble single-channel slip ring carries significant weight in the functioning of various applications. By considering all the outlined factors, users can make informed decisions that lead to long-lasting and efficient use of these mechanical marvels.

FAQs about Single-Channel Slip Ring

Q: What can impact the longevity of my single-channel slip ring?

A: Various factors can impact the longevity of a single-channel slip ring, including wear and tear, maintenance routines, electrical noise, and environmental factors like dust and moisture.

Q: How can I pick the right single-channel slip ring for my application?

A: When picking a single-channel slip ring, consider the specific requirements of your application, electrical and mechanical specifications, environmental considerations, and the manufacturer’s reputation and support services.

Q: What Is a Single-Channel Slip Ring and How Does It Work?

A: A single-channel slip ring is a device designed to transmit power or data from a stationary part of a system to a rotating part. It consists of a ring that maintains continuous electrical contact with a rotating brush or contact. As one part of the slip ring rotates with the machine component, it ensures uninterrupted electrical connectivity by compensating for the rotational movement. This mechanism is crucial for systems requiring constant power supply or data exchange in parts that move in a circular motion.

Q: What Are the Key Advantages of Using a Single-Channel Slip Ring?

A: Single-channel slip rings are celebrated for their simplicity and reliability. They enable complex rotational mechanisms by facilitating a continuous electrical connection between stationary and moving parts. This not only enhances system functionality but also reduces wear and tear associated with flexing cables. Moreover, these slip rings are adaptable to a myriad of environments and applications, from industrial machinery to medical equipment, owing to their compact design and efficient operation.

Q: How Do I Choose the Right Single-Channel Slip Ring for My Application?

A: Selecting the appropriate single-channel slip ring involves considering several factors:

- Application Requirements: Define whether the slip ring will primarily transmit power, data, or both, and consider the required bandwidth and signal integrity.

- Electrical Specifications: Match the voltage and current rating with your system’s specifications to ensure compatibility.

- Mechanical Considerations: Factor in the operating speed (RPM), mounting space, and environment; harsh conditions may require slip rings with higher durability or protection ratings.

- Manufacturer Quality: Opt for reputable manufacturers known for quality products and support. It’s beneficial to consider customization options for unique system requirements.

Q: Can Single-Channel Slip Rings Be Used in Harsh Environmental Conditions?

A: Yes, single-channel slip rings can be designed and manufactured to withstand harsh environmental conditions, including high moisture levels, dust, and extreme temperatures. This is achieved through the use of durable materials, specialized coatings, and seals that protect the internal components. When selecting a slip ring, it’s crucial to specify the environmental conditions it will face to ensure the manufacturer provides a suitably protected device.

Q: What Is the Lifespan of a Single-Channel Slip Ring, and How Can It Be Extended?

A: The lifespan of a single-channel slip ring depends on several factors, including the quality of materials, operational environment, and load conditions. Under typical circumstances, a well-made slip ring can last for millions of rotations. To extend the lifespan:

- Regular Maintenance: Perform periodic inspections and cleanings to remove debris and ensure good electrical contact.

- Proper Installation: Follow the manufacturer’s instructions for installation to avoid undue stress or misalignment.

- Choose Quality: Initially selecting high-quality slip rings from reputable manufacturers can greatly contribute to longevity.

Q: How Are Single-Channel Slip Rings Integrated into IoT Systems?

A: In IoT systems, single-channel slip rings facilitate the transmission of data between rotating and stationary parts, allowing for seamless connectivity and communication within a networked environment. They enable the inclusion of sensors and actuators on rotating parts of machinery, essential for monitoring and control in smart factories, autonomous vehicles, and other applications of the Internet of Things. The key is ensuring that the slip ring can support the required data rates and signal integrity for IoT functionalities.