what is a squirrel cage? Imagine pressing a button on your washing machine, adjusting the settings on your air conditioner, or starting your car. Unbeknownst to many, at the heart of these common tasks lies an unsung hero: the squirrel cage induction motor. Despite its peculiar name, which might conjure images of a small rodent running on a wheel, the “squirrel cage” plays a pivotal role in the modern world, driving much of the machinery and appliances we rely on daily. But what exactly is a squirrel cage, and why does it matter so much in our lives?

This article aims to shed light on the enigmatic component known as the squirrel cage. Designed to bridge the knowledge gap for a broad audience — from inquisitive students to seasoned professionals in the field of engineering and technology — we embark on a journey to demystify this crucial yet often overlooked part of induction motors. Through an engaging exploration, we will uncover not just the fundamentals of the squirrel cage but also delve into its construction, operational principles, significance in efficiency and performance, and much more.

What Is a Squirrel Cage – The Fundamental Concepts

Have you ever observed a hamster running endlessly on its wheel, its tiny feet blurring as they race around in circles? In the world of electric motors, there exists a component whose name and structure share a surprising resemblance with the aforementioned hamster’s cage wheel. This component is known as a “squirrel cage”, and it inhabits the heart of induction motors virtually everywhere.

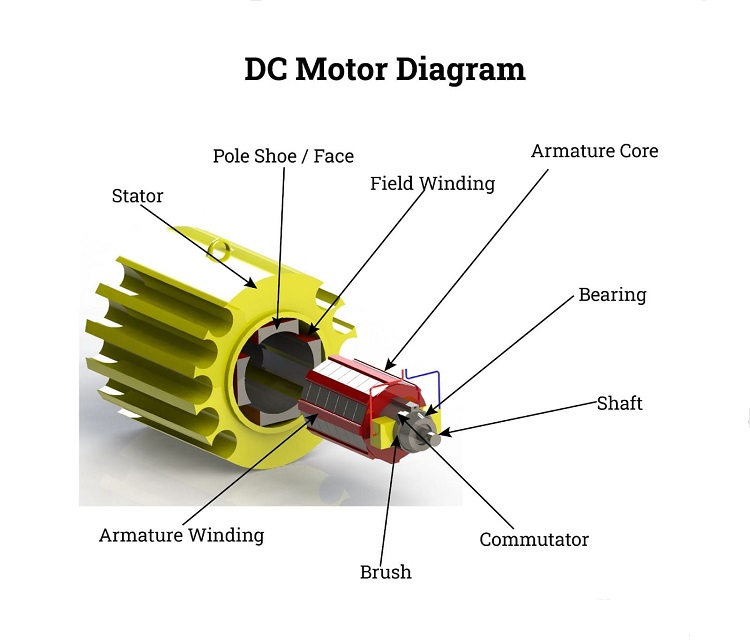

Before we venture deeper into the world of squirrel cages, it’s essential to first understand what an induction motor is. As a type of electric motor, an induction motor harnesses the power of electromagnetic induction — a fundamental principle discovered by physicist Michael Faraday in the early 19th century. The induction motor operates by generating a magnetic field, which then induces a current that propels the motor’s rotor, thus driving the overall operation of the motor.

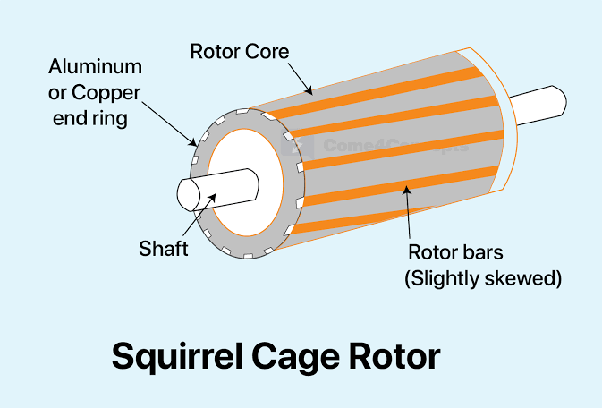

The core of this rotor is where our not-so-furry friend, the squirrel cage, resides. Contrary to what the amusing moniker might suggest, a squirrel cage isn’t a literal cage for a squirrel. Rather, the term ‘squirrel cage’ is a nickname for the rotor found in an induction motor owing to its distinctive structure. It essentially involves a series of conducting bars, aligned parallel, and connected at the ends with end rings, forming a loop that resembles a squirrel’s exercise wheel, albeit devoid of any critters.

Why is the squirrel cage such a pivotal component? Its primary role is to enhance the effect of the magnetic field created within the motor. When the motor is active, the alternating current (AC) supply creates a rotating magnetic field around the stator (the stationary part of the motor). This changing magnetic field then induces a current in the conducting bars of the squirrel cage, generating its own magnetic field, which reacts with the initial field produced by the stator. The interaction between these fields generates torque, causing the rotor — and thus, the motor — to turn. In essence, without the squirrel cage, that washing machine, air conditioner, or even your car might not work quite as expected!

In succinct terms, the squirrel cage, worthy of its quirky name, greatly contributes to the everyday magic of electric motors turning electrical energy into useful mechanical energy. Its design elements, acting as the horsepower of many machines, underscore its importance in our era of technology and mechanization. And while it might not involve any actual squirrels doing laps on an exercise wheel, the concept is no less fascinating! Stay tuned as we delve further into what makes a squirrel cage come alive — literally and figuratively — in the upcoming chapters.

What Is a Squirrel Cage Made Of – Materials and Construction

Stepping into the heart of an induction motor, we unravel the essence of what brings energy to life: the squirrel cage rotor. The careful orchestration of materials and methods in its creation is a testament to engineering ingenuity. Let’s dive into the composition and construction of squirrel cage rotors, exploring why certain materials are chosen and how these rotors take shape from raw components to crucial elements of electric motors.

The Choice of Materials

The squirrel cage is not just any component; its construction is a thoughtful process that involves selecting materials that strike the perfect balance between conductivity and durability. The bars of the rotor are typically made from aluminum or copper, both known for their excellent electrical conductivity. The reason for this preference lies in their ability to efficiently conduct electrical current, which directly correlates to the motor’s overall performance and efficiency.

Aluminum is often favored for its cost-effectiveness and lightweight properties, making it an excellent choice for smaller motors or applications where overall motor weight is a critical factor. Copper, while more expensive, offers superior conductivity and is thus preferred in high-performance settings where efficiency is paramount. Each choice represents a trade-off between cost and efficiency, shaped by the intended application of the motor.

The end rings that connect these bars, completing the circuit, are made from the same material to ensure consistent conductivity throughout. This uniformity is paramount in minimizing energy loss and maximizing the efficiency of energy transfer within the motor.

Manufacturing Process: Crafting the Cage

Creating a squirrel cage rotor involves precision engineering and a series of steps that transform raw materials into the spinning heart of an induction motor. The process generally follows these stages:

Casting: The most common method for forming the squirrel cage structure is die casting for aluminum rotors. In this process, molten aluminum is poured into a precision-engineered mold that shapes the rotor’s conducting bars and end rings as a single, cohesive unit. This method is prized for its ability to produce rotors with high conductivity and minimal imperfections, which are crucial for efficient motor operation.

Insertion into the Laminations: The cast rotor is then inserted into the rotor laminations, which are thin layers of electrical steel stacked and pressed together. These laminations serve a dual purpose: they reduce energy losses due to eddy currents and provide the magnetic structure that interacts with the stator’s magnetic field. Precision is key in this step to ensure the rotor bars are perfectly aligned with the laminations for optimal performance.

Machining: After the casting and lamination steps, the rotor undergoes machining. This process fine-tunes the dimensions, ensuring that the rotor can spin freely within the stator’s magnetic field without contact, minimizing wear and maximizing efficiency.

Through these stages, the squirrel cage rotor comes to life, prepared to convert electrical energy into mechanical energy that powers everything from household appliances to industrial machinery.

The meticulous selection of materials and the precision of the manufacturing process underscore the importance of the squirrel cage in the efficiency and longevity of induction motors. As we delve deeper into the operational dynamics in the next chapter, we will uncover how these carefully crafted components come together to create motion from the invisible forces of electromagnetism.

Operative Dynamics: What Is a Squirrel Cage’s Function?

In the previous chapters, we sketched the silhouette of the squirrel cage—its curious name and its crafting from metals that boast impressive electrical personalities. Now, let’s breathe life into this static structure and set it in motion. Chapter 3 invites you to observe the squirrel cage come alive, its role not just confined to spinning quietly in an electric motor but anchoring the very spirit of a machine’s movement.

The Heartbeat of an Electric Motor

Consider the squirrel cage not just as a component but as the pulse in the motor’s circulatory system. The cage is static when at a standstill, but it has the potential for energy and movement—a sleeping dynamo awaiting the call to action.

When electricity is introduced, the rotor, with its squirrel cage at the core, takes on a crucial set of responsibilities:

- Conducting Induced Current: As the magnetic field from the stator sweeps across the bars of the squirrel cage, a current is induced, living up to Faraday’s law of electromagnetic induction.

- Creating Torque: This flow of current generates a magnetic field around each rotor bar. The interaction of these rotor bar fields with the stator’s magnetic field produces torque—the necessary twist that heralds motion.

- Transferring Energy: The squirrel cage, now brimming with induced currents and magnetic interactions, becomes the conduit for transferring electrical energy into mechanical energy, setting the rotor in motion and turning the shaft that performs work, be it spinning a washing machine drum or drawing air through a ventilation system.

The Principle of Electromagnetic Induction at Play

The stage for the squirrel cage’s dance is set by the principle of electromagnetic induction. Here’s the scene: an electrical supply powers the stator windings, creating a magnetic field that rotates around the inside of the motor. Picture this field as invisible waves of force, moving in such a way that when they encounter the conducting bars of the squirrel cage, they don’t just pass by—they induce electric currents in the rotor’s bars.

The beauty of this process entails that the forces on the conducting bars of the squirrel cage are constantly changing as the magnetic field rotates, and according to Lenz’s law, these bars react by creating their own magnetic fields in opposition. This interaction produces the much-needed torque due to the magnetic forces at play between the stator and the rotor.

Real-World Symphony of Motion

Visualize a large industrial fan: behind its gentle hum and the slow movement of its massive blades is the squirrel cage, the orchestrator of rotation. This silent and unseen interaction of magnetic fields and electric currents is why the fan can do its job—moving air on a grand scale.

Similarly, in your car, when you ignite the engine, an induction motor-powered start system with a squirrel cage rotor springs to life, turning over the engine until it catches and runs on its internal combustion process.

Addressing Common Questions

One common question is about the speed at which the squirrel cage rotates. It doesn’t quite sync with the magnetic field’s rotation—a phenomenon known as ‘slip’. This slight lag allows for the induction process to continue as if the rotor were trying to ‘catch up’ with the magnetic field, maintaining a perpetual chase that ensures continuous energy transfer.

The squirrel cage’s raison d’être is deeply rooted in its ability to keep this chase going. By understanding the operative dynamics of squirrel cages, we gain a deeper appreciation of the silent work that translates into the myriad functionalities we often take for granted. Stay tuned as we explore how these dynamics affect the efficiency and performance of motors in our next insightful chapter.

What Is a Squirrel Cage’s Role in Efficiency and Performance?

Now that we understand the function and operational dynamics of a squirrel cage, let’s examine its pivotal role in shaping the efficiency and performance of motors. Unveiling how the design and choice of materials impact the critical domains of durability and conductivity, Chapter 4 demonstrates how the humble squirrel cage punches above its weight in the world of induction motors.

Design Determines Performance

The squirrel cage’s design isn’t something to be treated lightly—it holds the potential to make or break the performance of its hosted motor. Altering the number and shape of the bars and the materials utilized can lead to motors optimized for a variety of tasks, from household appliances to heavy-duty industrial machinery.

Take, for instance, the number of bars in a squirrel cage. It has been found that by increasing the number of bars, we can achieve a higher starting torque. This adjustment gives motors more power during the initial phase of operation, which can be useful for heavy-duty applications such as starting large fans or pumps.

On the flip side, rotors with fewer bars have a greater speed range, making them suitable for applications requiring speed variation, like certain types of machining operations. As a result, the design of a squirrel cage rotor should always consider the intended application of the motor, balancing torque and speed in a way that gives the best performance.

Durability Versus Conductivity: The Enduring Balancing Act

As covered in Chapter 2, the choice of materials for manufacturing squirrel cage rotors involves a trade-off between durability and conductivity. To recap, copper rotors offer better conductivity than their aluminum counterparts, which can significantly increase the efficiency and power factor of the motor. However, copper is also more expensive and heavier, which could increase the overall cost and weight of the motor.

In contrast, aluminum is a more cost-effective and lightweight option, making it a popular choice for many applications. However, aluminum’s lower conductivity than copper might lead to increased energy losses and lower efficiency. Hence, the choice between aluminum and copper often boils down to a balance between cost, weight, and efficiency requirements.

Case Study: Efficiency in Electric Vehicles

One interesting energy-efficiency case study worth mentioning is electric vehicles (EVs). In this scenario, every bit of energy saved contributes to the vehicle’s range. Therefore, EVs typically employ induction motors with copper-based squirrel cage rotors for their superior conductivity and high efficiency. With these rotors, EV manufacturers aim to make each charge last longer, squeezing as many miles as possible out of the battery.

Addressing Common Misconceptions

A common misconception is that the squirrel cage’s design and choice of materials don’t significantly affect a motor’s efficiency and performance. However, as we’ve seen, the design can dramatically shape a motor’s performance characteristics, and the materials can play a massive role in the motor’s overall efficiency.

To wrap things up, the design and building materials of a squirrel cage play an integral role in efficiency and performance factor within an induction motor’s world. These choices must be made thoughtfully, considering the application’s requirements and demands. Armed with this deeper understanding, join us in the next chapter as we delve into how squirrel cages are maintained and what happens when these components fail.

Maintenance Insights: What Is a Squirrel Cage’s Lifespan and Care?

Chapter 5 shifts our focus from the conceptual workings of a squirrel cage to the practical realm of its maintenance. We’ll shine a light on the typical lifespan of a squirrel cage and share tips to care for this unassuming component that’s essential to an induction motor’s functionality.

Lifespan: How Long Does a Squirrel Cage Last?

The squirrel cage of an induction motor typically enjoys a long life, seeking not the limelight but dutifully providing service for years. Due to its minimal wear and tear, a well-maintained squirrel cage can last up to 20 to 25 years before requiring significant attention or replacement.

However, it’s important to remember that the lifespan of a squirrel cage heavily relies on factors such as:

- Usage: A motor used in a high-demand environment, such as in heavy machinery operating around the clock, may wear out sooner than one used sporadically.

- Maintenance: Routine maintenance tasks such as ensuring proper lubrication and cleanliness can drastically prolong the lifespan of the squirrel cage as well as the motor itself.

- Operating Conditions: Harsh conditions like extreme temperatures, heavy dust or moisture environments, and overloading can cause an early demise of the cage.

Maintaining and Troubleshooting: A Guide to Squirrel Cage Longevity

While squirrel cage rotors are inherently low-maintenance due to their simplicity and ruggedness, here are some best practices that can ensure you get the most out of your cage:

- Regular Inspection: Keep an eye out for signs of wear or damage during routine maintenance checks—a warped cage, burns on the bars, or loose conductors can indicate potential issues.

- Proper Lubrication: Although the squirrel cage itself doesn’t require lubrication, motor bearings do. Ensure the motor is properly lubricated to avoid excess heat or friction that could affect the squirrel cage.

- Voltage and Current Checks: Monitoring voltage and current during operation can help identify any irregularities in the operation, which may point to problems within the squirrel cage or other motor components.

Understanding and acting on these maintenance practices can considerably extend the lifespan of the squirrel cage, contributing to the cost-effectiveness and functionality of motors in different applications.

Case Study: Squirrel Cage in Wind Turbines

For a quick glimpse into a real-world application, consider wind turbines. These machines are placed in conditions notorious for mechanical stress and environmental extremes—high winds, dramatic temperature shifts, and continuous operation. Thanks to regular maintenance and inspections, the squirrel cages within their induction generators can continue functioning effectively for many years, harnessing the power of the wind with unbroken resolve.

Addressing Common Questions

Many people wonder if a squirrel cage will eventually wear out. While the cage itself is quite robust, it’s not indestructible. As the core of the rotor spinning within the magnetic field, it can succumb to stresses over an extended period. However, with proper care, it can serve faithfully for many years—one of the reasons induction motors prevail in numerous applications today.

In conclusion, understanding the lifespan and maintenance aspects of a squirrel cage can considerably enhance the returns from your induction motors. Stay tuned for the following chapter, where we will journey into more complex induction motor types, unlocking further secrets of their operation and maintenance.

Innovative Applications: What Is a Squirrel Cage Used For?

As we edge deeper into the world of squirrel cages and induction motors, a crucial question arises: what are squirrel cages used for? Chapter 6 unveils this vast, intricate tapestry, highlighting applications from industrial to everyday household usage. At the same time, it introduces readers to some offbeat, unconventional usages that cast new light on the versatility of squirrel cage motors.

Everyday Heroes: Squirrel Cages in Industrial and Household Applications

Believe it or not, squirrel cage induction motors are so ubiquitous that they quietly hum in the background of most aspects of our lives.

When you visit your local supermarket, the compressors in the refrigeration units use squirrel cage induction motors. Take a trip to the elevator – yes, you’re aided by squirrel-caged forces. Air conditioning systems, from commercial to smaller unitary systems, deploy induction motors. Factories and manufacturing units heavily rely on them to drive conveyor belts, pumps, and a wide spectrum of machinery.

Turning to your household, induction motors spin washing machines, whisk mixers in your kitchen, and power your vacuum cleaners. They even drive the fan in your laptop! The common thread behind these diverse applications is the humble squirrel cage induction motor.

Unconventional Applications: Where You Wouldn’t Expect Squirrel Cages

Alongside their traditional roles, squirrel cages have a fascinating knack for appearing in less conventional set-ups. Here are a few examples:

- Wind Turbines: As already seen in Chapter 5, wind turbines pair well with induction generators that house squirrel cages. They convert mechanical energy from the spinning blades into electricity, powering homes with renewable energy.

- Electric Vehicles: Induction motors with squirrel cages offer excellent torque and efficiency—key factors that are prioritized in electric vehicles’ power systems. Tesla Motors, a prominent player in the EV market, employs induction motors precisely for these reasons.

- Water Treatment Plants: Squirrel cage induction motors play a significant role in water and wastewater treatment plants, where they power centrifuges and pumps to ensure clean water flows to our homes.

- Amusement Parks: If you’ve enjoyed a thrilling roller coaster ride or a tranquil Ferris wheel experience, induction motors, with their efficient torque control, were likely involved, adding another dimension to the squirrel cage’s influential reach.

Addressing Common Questions

It’s easy to overlook the squirrel cage motor, due to its ubiquitous nature. However, it silently powers a vast portion of our daily life, from mundane household chores to immense industrial processes. Its versatility, reliability, and cost-effectiveness contribute to its prevalence, making it the unsung hero of modern electrical machinery.

As we conclude Chapter 6, there’s no denying the pervasive presence and sweeping influence of squirrel cage induction motors. Having built a solid understanding of their hardware, operation, and application, let’s delve into future trends and prospective advancements in the final chapter of our exploration.

What Is a Squirrel Cage’s Impact on Modern Technologies?

As we approach the culmination of our journey through the intricate world of squirrel cage induction motors, Chapter 7 zooms out to ponder a broader perspective: the significant impact of these motors on modern technology and automation.

The Evolution of Squirrel Cage Induction Motors

The squirrel cage induction motor, since its inception by Nikola Tesla in the late 19th century, has undergone a remarkable evolution. Initially valued for its simplicity and reliability, the motor has seen enhancements in materials, design, and control techniques, keeping pace with technological advancements and increasing demands for efficiency.

Modern squirrel cage motors benefit from high-quality magnetic materials, precision manufacturing processes, and sophisticated electronic control systems. These improvements have made them more efficient, adaptable, and capable of addressing a broader range of applications than ever before.

Pioneering Modern Technology and Automation

The real testament to the squirrel cage induction motor’s groundbreaking impact lies in its role in modern automation and technology sectors:

- Manufacturing Revolution: Induction motors have been central to automating manufacturing processes. From asembly lines that produce automobiles to robots that assemble electronic devices, squirrel cage motors provide motion, enhancing productivity and precision.

- Rise of Renewable Energy: With the global shift towards sustainable energy, squirrel cage induction motors in wind and hydroelectric power stations play a vital role in converting natural forces into electricity, underscoring their importance in the green revolution.

- Infrastructure and Transportation: In public transportation systems, including electric trains and metro systems, squirrel cage motors drive the wheels of progress, quite literally. They ensure efficient, reliable service across the globe, moving millions of passengers daily.

- Technological Integration into Daily Life: Beyond these vast, industrial applications, squirrel cage induction motors weave into the fabric of daily life, powering everything from household appliances to HVAC systems, showcasing their versatility and impact.

Future Directions: Where Do We Go from Here?

As technology continues to evolve, so too will squirrel cage induction motors. The future holds promise for further enhancements in efficiency, integration of smart technologies for predictive maintenance, and perhaps even more compact designs achieving higher power densities. The ongoing research in materials science and electromagnetic theory promises to push these motors into new realms of performance and sustainability.

Addressing Common Misconceptions

A common misunderstanding is that the simplicity of squirrel cage motors limits their efficiency and application. However, as we’ve explored, their impact on modern technology disproves this notion. Through continuous innovation, squirrel cage induction motors remain at the forefront of electrical motor technology, adaptable across a myriad of applications. Their legacy and ongoing development reflect their indispensable role in the past, present, and future of human technological advancement.

In conclusion, the squirrel cage induction motor’s journey from a simple yet revolutionary design to a cornerstone of modern automation and technology showcases its lasting impact. As we look to the future, the potential for further innovation ensures that squirrel cage motors will continue to be vital components in the evolution of technology.

What Is a Squirrel Cage’s Future – Trends and Advancements

As we draw the curtains on our exploration of squirrel cage induction motors, it only benefits us to cast an eye toward the future. Chapter 8 delves into the realm of possibilities, exploring current trends in squirrel cage design and application, anticipating their trajectory, and envisioning a future molded by technological advancements.

Embracing the Present: Current Trends in Squirrel Cage Design and Application

While continuous improvements in materials and manufacturing play a significant part in ongoing advancements, there is an increasing emphasis on smart technologies. Here are some key trends shaping the present and future of squirrel cage induction motors:

- Energy Efficiency: In response to growing sustainability concerns worldwide, manufacturers focus on creating energy-efficient designs to lower energy consumption and reduce carbon footprints. This trend opens up advanced design possibilities for more efficient squirrel cage induction motors.

- IoT and Industry 4.0 Integration: With the emergence of the Industrial Internet of Things (IIoT) and Industry 4.0, smart technologies are increasingly integrated into motor systems. These enable real-time monitoring and predictive maintenance, enhancing the reliability and lifespan of the motors, including those house squirrel cages.

- Variable Speed Drives (VSDs): VSDs adjust the speed and torque of the motor according to the load, creating more energy-efficient and adaptable solutions. The integration of VSDs with squirrel cage induction motors offers increased control and responsiveness to varying loads.

Visioning the Future: Predicted Advancements

Harnessing these trends and looking further into the future, one can make educated predictions about potential advancements in squirrel cage induction motor design and application:

- Smart Motor Systems: Combining modern control systems, AI, and machine learning with squirrel cage motors could lead to ‘smart’ motors that can self-optimize performance, conduct self-diagnosis, and even schedule their own maintenance.

- Advanced Materials: Continued research into materials science could yield much more efficient and robust materials for squirrel cage construction. This could lead to motors with even greater efficiency and thermal performance, enhancing reliability and decreasing the energy cost.

- Customizable and Flexible Designs: As technology continues to evolve, there may be increasing demand for more customizable and adaptable motor designs to accommodate different applications. Such designs could offer variable configurations of the squirrel cage for specific performance characteristics.

Addressing the Crystal Ball: Evolving Technologies and Implications

Thinking of evolving technologies like artificial intelligence, quantum computing, nano-materials, and their potential implication on squirrel cage induction motors introduces an inspiring vista of possibilities. AI could revolutionize motor controls, making them even more energy-efficient, reliable, and predictive. Quantum computing could offer new design and simulation capabilities, and nano-materials might present opportunities for even lighter and more robust squirrel cages.

The future of squirrel cage induction motors echoes the promise of sustainable efficiency, advanced control, robust design, and versatile applications. As our journey ends, it’s clear that the journey of the squirrel cage induction motor is far from over. It continues to evolve and adapt, navigating the currents of technology with an unceasing hum, ready to embrace the challenges and opportunities of tomorrow.