This article offers an in-depth exploration of slip ring assy, crucial components in modern electrical systems allowing the transfer of power and signals to rotating platforms. From detailed insights into their structure and function to practical advice on selection, maintenance, and the latest advancements, this guide covers everything you need to know about slip ring assemblies.

Introduction to Slip Ring Assembly

A slip ring assembly, known in short as a slip ring assy, is a component at the heart of numerous electrical systems that powers our modern world. These assemblies enable electrical continuity in devices and machines where part of the system rotates, and the other part remains stationary. They represent a dependable solution to the complex task of transferring power and signals between these different parts.

Perhaps you’ve noticed a wind turbine turning gracefully against the sky or watched a lighthouse beam sweep across the ocean. Maybe you’ve benefited from an MRI scan or watched an amusement park ride in action. These are just a few examples where slip ring assemblies silently go about their work.

Slip ring assemblies are unique, unassuming devices mired in technicalities, yet they offer a solution to an age-old problem. Without them, each time a machine with rotary elements needed to transfer power or signals, it would end up with tangled wires, damaged connections, and inefficient operation.

In a world where rotational motion is fundamental to many devices and machinery, slip ring assemblies have become indispensable. Whether it’s in aerospace, defense, robotics, medical scanning, electrical generators or numerous other applications, slip ring assemblies provide an answer to a crucial need, performing a role that often goes unrecognized but is essential for our technologically driven world.

Slip Ring Assembly in Detail

Overview

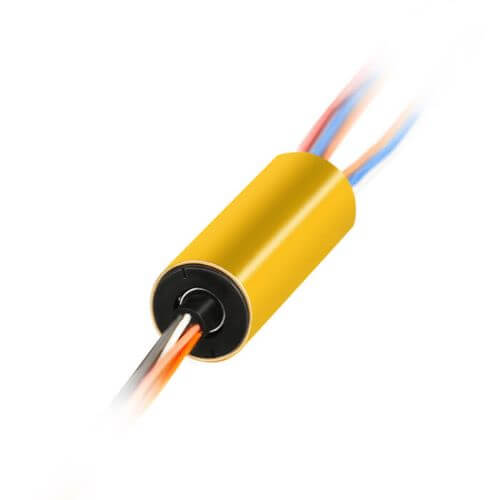

At its most fundamental, a slip ring assembly consists of a rotating metal ring and stationary metal brushes. The brushes, held against the rings by spring tension or gravity, convey electrical currents or signals through their contact with the rotating ring. Thanks to this simple yet elegant design, slip ring assemblies maintain an uninterrupted electrical connection between a stationary component, such as the base of a machine, and a moving component, like a rotating arm.

Types

The diversity of slip ring types reflects the wide array of applications they serve:

These compact, cylindrical designs are used in space-constrained environments wherein a small form factor is crucial, like in robotics or compact cameras.

Characterized by a hollow shaft, these slip rings accommodate other mechanical components or wiring. This is the design of choice for applications requiring central space for shaft mounting, like turntables or wind turbines.

Filled with liquid mercury, they offer the advantage of reduced electrical resistance and are typically used where high-speed data transmission is required, but always with careful consideration of their environmental hazards.

With a flat, disc-like shape that offers a short axial length, these slip rings are suitable for applications where space is limited in the vertical direction, such as in CCTV camera systems.

Function

The primary functionality of a slip ring assembly is transmission — it is the bridge that carries electrical power and data signals across the divide between a stationary body and a rotating one. This is a vital need in applications where a part of the device must spin freely, such as in the case of rotary tables, medical machinery, or robotic arms, without resulting in twisted wires or interrupted signals.

Components

While the exact configuration might vary, the typical components of a slip ring assembly include:

- Rings: Conductive circular bands made from durable metals that rotate with the shaft and are the main pathway for the electrical current.

- Brushes: Usually made of graphite or precious metals, brushes maintain an electrical connection with the rings.

- Housing: The casing that protects the internal components from dust, debris, and other contaminants.

- Insulation Materials: Electrical insulation that prevents short circuits and can be made from various plastics or ceramics, ensuring safety and reliability.

- Bearing: Precision bearings often support the rotation of the slip ring assembly, ensuring smooth and stable movement.

A slip ring assembly is more than just a sum of its parts; it’s the synergy of these components that creates a dynamic system capable of handling the complex demands of transmitting data and power in countless applications. Its design and build are attributes to the ingenuity that drives our continuously evolving electrical and mechanical needs.

Slip Ring Assembly: Areas of Application

Slip ring assemblies find their place in a staggering array of industries and machinery, serving as pivotal components that enable smooth operation and functionality. Their versatility and adaptability make them indispensable in numerous applications, ranging from renewable energy to advanced medical systems. Here’s a closer look at the roles slip rings play across different scenarios:

Wind Turbines

In the renewable energy sector, particularly wind energy, slip ring assemblies are used within the turbines’ nacelles — the housing on top of the tower that contains the generator and other components. They enable the transmission of electrical power from the rotating blades to the stationary generator and allow data signals to move between the control systems and the moving parts of the turbine. This continuous flow of power and data is essential for monitoring, controlling, and optimizing wind turbine performance, thereby ensuring efficient energy production.

Medical Equipment

The medical industry benefits immensely from slip ring technology, especially in imaging equipment such as CT (Computed Tomography) scanners. In these machines, slip ring assemblies facilitate the transmission of power and high-speed data between the rotating gantry, which houses the X-ray source and detectors, and the stationary part of the scanner. This allows for the continuous rotation of the gantry necessary to produce detailed cross-sectional images of the body, leading to accurate diagnoses without compromising the integrity of the transmitted data or power supply.

Radar Systems

Radar systems, whether used for military, weather monitoring, air traffic control, or maritime navigation, rely on the rotational capability of the radar antenna to provide 360-degree coverage. Slip rings in these systems ensure that as the antenna rotates, it remains electronically connected to the stationary base, allowing for the continuous operation necessary for real-time data collection and processing. This uninterrupted electrical connection is crucial for the reliable performance of radar systems in critical applications.

CCTV Systems

In the realm of security and surveillance, CCTV systems often require pan-tilt-zoom (PTZ) functionality to cover wide areas and focus on specific targets. Slip ring assemblies in PTZ cameras provide the electrical continuity needed for the cameras to rotate without restricting their motion or tangling wires. This ability to rotate endlessly allows for comprehensive monitoring and ensures that the security systems function optimally, offering uninterrupted surveillance and control.

These scenarios underscore the critical role slip rings play in enabling functionality and enhancing the reliability of diverse systems across various industries. By providing a reliable method for transmitting power and data across moving interfaces, slip ring assemblies contribute greatly to the efficiency, performance, and operational capabilities of the equipment they are part of. Their usage across different fields highlights not just their versatility but also the universal challenge they address in bridging the gap between stationary and rotating systems.

Choosing and Sizing a Slip Ring Assembly

The selection and sizing of a slip ring assembly are critical decisions that impact the efficiency, reliability, and lifespan of the equipment it will be integrated with. These decisions require careful consideration of various technical and environmental factors to ensure the slip ring not only fits the immediate needs of the application but also adheres to the highest standards of durability and performance over its intended operational life.

Factors to Consider When Choosing a Slip Ring Assembly:

- Current and Voltage Requirements: One of the primary considerations is the electrical load the slip ring assembly must carry. Understanding the current and voltage requirements of your application ensures that the slip ring can handle the electrical power without overheating or failure.

- Speed of Rotation: The operational speed of the rotating part of the machinery greatly influences the selection of a slip ring. Higher rotation speeds may require slip rings made with specific materials or designs to minimize wear and ensure smooth operation.

- Required Lifespan: Considering the expected operational lifespan of the slip ring assembly is crucial. Factors such as the quality of materials, type of brushes (metal or graphite), and maintenance access impact the longevity of the slip ring in its application.

- Environmental Conditions: The environment in which the slip ring will operate can significantly affect its performance. Conditions such as extreme temperatures, humidity, exposure to corrosive substances, or the presence of dust and debris necessitate selecting slip rings with appropriate protective features and construction materials.

- Size and Space Constraints: The physical space available for the slip ring assembly within the machinery dictates the maximum size of the slip ring. Compact designs like capsule slip rings may be favored in space-constrained applications.

- Signal and Data Transmission Needs: For applications requiring the transmission of signals or data (in addition to power), the slip ring assembly must be designed to minimize noise and interference, ensuring reliable communication.

Determining the Size of the Slip Ring Assembly:

The correct sizing of a slip ring assembly is a multi-faceted process that involves:

- Understanding Load Specifications: Starting with the basics, know the maximum current (Amps) and voltage (Volts) that the assembly must support.

- Evaluating Mechanical Constraints: Assess the mechanical integration points, considering the diameter of the assembly and the length of the slip ring body. The size and type of bearings used also play into this evaluation, especially in high-speed applications.

- Accounting for Future Needs: Consider potential increases in power or data transmission requirements in the future to avoid the need for premature replacement.

- Assessing Signal Types: If transferring data or control signals, identify the type (analog, digital, frequency, etc.) and the required integrity of these signals, which may affect the design and consequently, the size of the slip ring.

- Consulting with Experts: Given the complexities involved, consultation with slip ring manufacturers or specialists can provide valuable insights, ensuring that all factors are considered and the most suitable size and type of slip ring assembly is selected.

In conclusion, choosing and sizing a slip ring assembly is a nuanced process that requires a comprehensive understanding of the application’s electrical, mechanical, and environmental demands. By thoroughly considering these factors, one can ensure that the selected slip ring enhances the functionality and reliability of the equipment, ultimately contributing to its success in its respective applications.

Slip Ring Assembly: Installation and Maintenance

For ensuring the long-term performance and reliability of machinery incorporating slip ring assemblies, adhering to proper installation procedures and maintenance regimens is paramount. The intricacies of slip ring technology mandate a thoughtful approach to how these components are installed, inspected, and maintained.

Installation Guidelines

- Comprehend the Manual: Begin with a thorough review of the manufacturer’s installation manual. Each slip ring assembly has unique features and requirements that must be understood.

- Environmental Considerations: Evaluate the installation environment to avoid placing the slip ring assembly in locations subject to excessive moisture, dust, or extreme temperatures, unless specifically designed for such conditions.

- Electrical Connections: Ensure that electrical connections are secure and conform to the specifications. Incorrect wiring or loose connections can lead to malfunction or damage.

- Alignment: Proper alignment is crucial. Misalignment between the stationary and rotating parts can cause undue wear and tear, leading to premature failure.

- Testing: Post-installation, it’s essential to conduct a comprehensive test to verify that the assembly operates correctly under dynamic conditions.

Routine and Preventive Maintenance

Routine maintenance serves as the linchpin for the operational integrity and longevity of slip ring assemblies. A well-structured maintenance schedule includes:

- Regular Inspections: Conduct periodic visual inspections for signs of wear and tear, especially on contact surfaces and brushes.

- Cleaning: Keeping slip rings clean from dust and debris is vital. Use recommended cleaning agents and procedures as per the manufacturer’s guidance.

- Lubrication: Some slip ring assemblies require lubrication for smooth operation; always utilize the lubricants specified by the manufacturer.

- Brush Wear Check: Regularly check the condition of the brushes. Worn brushes should be replaced timely to maintain optimal contact with the ring.

- Electrical Testing: Periodically perform electrical continuity and insulation resistance tests to ensure the assembly is transferring power and signals effectively.

Troubleshooting and Repairs

Despite best efforts in maintenance, issues may arise. Being prepared to address common problems ensures minimal downtime:

- Wear & Tear on Brushes: Excessive wear can lead to poor contact and signal loss. If brushes are worn unevenly or more than the acceptable limit, replacing them is necessary.

- Broken Wires: Movement and vibration can lead to fatigue and breakage of wires. Inspect connections regularly and repair or replace wires as needed.

- Intermittent Signals: If experiencing intermittent signal or power transmission, check for loose connections, worn brushes, or debris causing poor contact.

- Noise and Vibration: Unusual noise or vibration can indicate misalignment or bearing issues. Realign the assembly or inspect bearings for wear and replace them if needed.

Repair Guide

When repairs are necessary, refer to the manufacturer’s guide for specific instructions. Many slip ring assemblies are modular, allowing for the replacement of individual components rather than the entire unit. Always ensure power is disconnected before attempting repairs, and consider professional assistance for complex issues.

In summation, the effective installation and diligent maintenance of slip ring assemblies are not merely best practices but essential rituals that safeguard the assembly’s functionality and extend its service life. By adhering to these guidelines, businesses can anticipate reliable operation and forestall the common pitfalls associated with slip ring assemblies, ensuring uninterrupted operation of their machinery.

Slip Ring Assembly: Trends and Advances

The field of slip ring assemblies, despite its roots deep within traditional engineering, is far from static. Progressions in materials science, computing, and manufacturing technologies have led to significant advancements in slip ring design and functionality. Simultaneously, the evolving demands of myriad industries continue to propel innovation forward, spotlighting new applications and future trends that will likely shape the slip ring assembly industry.

Industry Advances and Technologies

- Innovative Materials: Advancements in materials science have introduced new alloys and composite materials into slip ring design. For instance, the use of precious metals for contact surfaces and brushes enhances conductivity and reduces corrosion, ensuring reliable data and power transfer.

- Digital Technology Integration: The incorporation of digital technologies, such as fiber optic rotary joints (FORJs), has been gaining momentum. Providing virtually unlimited bandwidth, fiber optics are ideal for applications requiring high-speed data transmission.

- Efficiency Improvements: The push for better energy efficiency has led to the development of low-resistance slip rings which reduce power dissipation, making them more sustainable and economical in the long run.

- New Applications: The surge of interest and investment in renewable energy, particularly wind power, has triggered the increased use of slip ring assemblies in wind turbines. Similarly, space exploration, unmanned vehicles, and advanced robotics are emerging fields where slip ring technology is being applied.

Future Trends

As we gaze into the future of slip ring assemblies, several trends present themselves as likely game-changers:

- Miniaturization: With modern machinery favoring compact and efficient designs, the trend towards miniaturization of slip ring assemblies is expected to continue.

- Intelligent Slip Rings: The convergence of AI and IoT technology with slip ring assemblies may redefine their functionality, leading to the rise of intelligent slip rings with self-diagnostic and predictive failure capabilities.

- Increased Customization: As applications become more diverse, the demand for custom slip rings tailored to specific industry requirements is expected to rise.

- Enhanced Durability: Slip rings capable of withstanding harsh environments and heavy-duty operations are likely to drive future designs. This trend is propelled by industries like mining, military, and heavy manufacturing that demand durable and reliable components.

- Sustainability: With environmental concerns taking center stage, the development of eco-friendly, low-emission slip rings will likely be a potent focus area in the future.

In conclusion, the landscape of slip ring assemblies is nothing short of dynamic, reflecting both the pace of contemporary technological advancements as well as the evolving needs of industries around the globe. As the slip ring assembly industry continues to innovate and evolve, these components look set to adapt and serve an even broader range of applications, reinforcing their central role and indispensability in the machinery of the future.

Conclusion

Slip ring assemblies are indispensable in enabling the functionality of a wide range of rotational systems. Understanding their types, applications, and maintenance requirements is crucial for professionals in fields relying on these components. As technology advances, keeping abreast of the latest developments and trends in slip ring design and application will remain essential.

FAQs about Slip Ring Assembly

Q: How long do slip ring assemblies typically last?

A: The lifespan varies depending on type, usage, and maintenance, but well-maintained assemblies can last several years.

Q: Can slip ring assemblies be repaired?

A: Yes, they can often be repaired, especially if issues like brush wear or minor electrical faults are identified early.

Q: Are there any safety concerns with mercury-filled slip ring assemblies?

A: Yes, due to the toxicity of mercury, these types of slip rings are subject to strict usage regulations and are not suitable for all applications.

Q: How can I detect wear and tear in a slip ring assembly?

A: Signs include erratic performance, increased electrical resistance, visible wear on brushes, and unusual noises during operation. Regular inspections help in early detection.

Q: What is a slip ring assembly?

A: A slip ring assembly, often just called a slip ring, is an electromechanical device that allows for the transmission of power and electrical signals from a stationary to a rotating structure. It consists of a rotating ring and stationary brushes or contacts that maintain an electrical connection between the rotating and stationary parts.

Q: How do I choose the right slip ring for my application?

A: Selecting the right slip ring for your application involves considering several factors: the type of signal or data to be transmitted (power, digital, analog), current and voltage requirements, rotational speed, required lifespan, environmental conditions, space constraints, and any application-specific requirements.

Q: Can slip rings transmit data as well as power?

A: Yes, slip rings can transmit a variety of signals, including control signals, data, and analog signals, in addition to power. They are designed to maintain a constant, uninterrupted electrical connection through rotating interfaces.

Q: Are slip rings reliable for high-speed data transmission?

A: Slip rings equipped with high-performance materials and designed specifically for high-speed data transmission can be reliable. However, factors such as design quality, signal frequency, and environmental conditions play a significant role in overall reliability.

Q: What kind of maintenance do slip rings require?

A: Slip rings require periodic inspection and maintenance to ensure reliable operation. This may include cleaning contact surfaces, checking and possibly replacing worn brushes, ensuring proper lubrication if applicable, and performing electrical tests to detect signs of wear or deterioration.

Q: Can slip rings operate in harsh environments?

A: Yes, there are slip rings designed for harsh environments, which may include those with high levels of moisture, extreme temperatures, exposure to corrosive chemicals, or substantial vibrations. These slip rings typically have specialized materials and enclosures to withstand tough conditions.

Q: What is the expected lifespan of a slip ring assembly?

A: The lifespan of a slip ring assembly varies widely depending on its usage, environmental conditions, maintenance, and the quality of its construction. Typically, manufacturers provide an estimated lifespan or operational cycle count, which can be a useful guideline.

Q: How do I know when to replace my slip ring assembly?

A: You should consider replacing your slip ring when you notice consistent performance issues such as erratic signals, excessive noise during operation, excessive wear on brushes and contacts, or physical damage. Regular maintenance checks can help identify these issues early on.

Q: Are there wireless alternatives to traditional slip rings?

A: Yes, wireless transfer technologies such as inductive power transfers (IPT) exist, which can replace slip rings in some applications. However, these alternatives have their limitations and might not be suitable for all scenarios, especially where high data transmission rates are required.

Q: Can slip rings be custom-designed for specific applications?

A: Absolutely. Many manufacturers offer custom slip ring solutions to meet unique application requirements. Custom designs may address specific electrical ratings, form factors, and environmental tolerances that are not met by standard slip ring assemblies.

See What We Can Do