Helicopter slip rings are essential components in the aviation industry, playing a crucial role in enhancing the efficiency, safety, and reliability of helicopter operations. These devices facilitate the transmission of electric power and signals between stationary and rotating parts of the aircraft, ensuring seamless communication and control. As helicopter systems continue to advance, the importance of these specialized slip rings has only grown. This comprehensive guide is designed to provide an in-depth understanding of helicopter slip rings, their various types, unique features, benefits, and the latest developments in this vital field. By exploring their workings, key components, and maintenance considerations, we hope to illustrate their significance within the broader context of modern aviation.

What are Helicopter Slip Rings?

Helicopter slip rings, at their most basic, fall under the broader category of slip rings – a type of electrical device designed to transmit power and signals between stationary and rotating parts in any electromechanical system. These typically consist of a rotating part (rotor) and a stationary part (stator), with electrical connections transferred through conductive rings and brushes.

However, helicopter slip rings come with a unique set of specifications that clearly differentiate them from regular slip rings. Given the complex and dynamic nature of helicopter operations, these slip rings are designed to withstand high rotational speeds, harsh operational conditions, and rapid changes in altitude and temperature. Furthermore, they are usually built with lightweight and compact features to fit within the restrictive spaces of an aircraft while reducing unnecessary weight.

In terms of function and purpose, helicopter slip rings primarily enable efficient and reliable power and signal transmission in the rotating systems of a helicopter. This function is crucial in maintaining continuous electrical connections, thereby allowing for smooth and constant communication, data transmission, and control. Without slip rings, the complex moving parts of a helicopter would face challenges in maintaining electrical continuity, potentially leading to issues such as flight instability or communication disruptions.

From powering avionic systems to transmitting data to flight control systems, helicopter slip rings serve as fundamental components in managing the intricate operations of helicopters. Understanding this context of their application is crucial in appreciating their role in enhancing the safety, reliability, and overall performance of helicopters.

Helicopter Slip Rings: Types

Within the aviation industry, there are several types of slip rings designed to meet the specific needs of helicopter systems. Let’s look at them more closely:

Compact Slip Rings

As their name suggests, these slip rings are small in size, making them suitable for installations where space is a constraint. Despite their compact size, they are capable of transmitting a wide range of data and power signals and are famed for their ruggedness and durability.

Through Bore Slip Rings

These slip rings are designed with a central hole or ‘bore’ that runs along their axis. This feature allows additional mechanical or optical components to be simultaneously incorporated, like rotary joints or fiber optical rotary joints, making their application versatile in complex systems.

Pancake Slip Rings

These are specialized slip rings designed with a flat, disc-like shape, hence the name ‘pancake.’ They are used when axial space (lengthwise space) is limited but radial space (sideways space) is ample. Their unique shape sets them apart and they are commonly used in places where standard cylindrical slip rings cannot fit.

Custom Slip Rings

For more unique applications where standard slip rings might not suffice, manufacturers offer custom slip rings. These are specially engineered to meet the specific requirements of the helicopter system in question, including accommodating extreme conditions or delivering high-performance results featuring multiple circuits, high speed, or high frequency.

Comparison and Application Examples

Each type of slip ring serves a different purpose depending on their design. Compact slip rings might be found in smaller rotorcraft where space is a premium, whereas through-bore slip rings might be used in helicopters with complex systems that require additional central passages. Pancake slip rings might be preferred in certain designs with ample radial space, while custom slip rings are the go-to solutions when the application demands are outside the capabilities of standard offerings.

Thus, the choice of slip rings greatly depends on a variety of factors, including the design and structure of the helicopter, application requirements, environmental conditions, and specific power and signal transmission needs.

Helicopter Slip Rings Typical Applications

Helicopter slip rings are essential components used to transfer electrical signals and power between stationary and rotating parts of a helicopter. Their primary applications include:

- Main Rotor Blade Pitch Control: Slip rings enable the transfer of control signals to the rotating main rotor blades, allowing for precise pitch adjustments necessary for flight control.

- Rotating Radar Systems: Helicopters equipped with radar systems use slip rings to transmit data and power between the stationary fuselage and the rotating radar antenna.

- Communication Systems: Slip rings facilitate the transfer of communication signals between the helicopter’s rotating components and the stationary systems, ensuring reliable communication.

- Sensor Systems: Various sensors mounted on the helicopter’s rotating parts, such as gyroscopes or accelerometers, use slip rings to transmit data to the main control systems.

- Power Transmission: Slip rings are used to transfer electrical power to various rotating components, such as lights, motors, or electronic devices mounted on the helicopter’s rotors.

- Weapon Systems: In military helicopters, slip rings are used to ensure the seamless operation of weapon systems that require electrical power and control signals while rotating.

These applications highlight the critical role of slip rings in ensuring the efficient and reliable operation of various helicopter systems.

Helicopter Slip Rings: Key Components

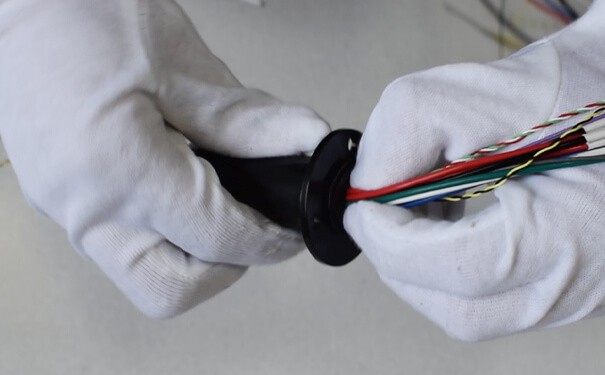

Helicopter slip rings comprise several critical components and are designed with various features to optimize their functionality. Here’s a closer look at these key elements:

Rotors and Stators

At their core, helicopter slip rings are made up of a rotating part, known as the rotor, and a stationary part, the stator. Electrical connections between these parts are made through a set of conductive rings and brushes, effectively allowing power and signals to pass from stationary components to the rotating ones, and vice versa.

Contact Materials

The contact materials used in slip rings greatly determine their performance and longevity. Precious metals like gold, silver, and platinum are often used due to their excellent conductivity and low resistance. They also offer the advantage of minimal noise interference, which is critical for maintaining clear and uninterrupted signal transmission.

Housing Materials

The housing material serves as a protective barrier for the slip ring components, shielding them from potentially damaging external conditions. Metals such as aircraft-grade aluminum or steel, known for their strength and resistance to corrosion, are typically used in the construction of the housing for the slip rings in helicopters.

Sealing and Protection

Protection from dust, moisture, and other external contaminants is critical for the smooth operation of slip rings. For this reason, the design incorporates specific sealing and protection features. Slip rings can be sealed using a variety of methods, the choice of which largely depends on the environmental conditions the slip ring will operate under.

Maintenance and Wear Considerations

Given the high-speed and harsh operating environments experienced by helicopter slip rings, design considerations for wear and ease of maintenance are crucial. The use of high-quality, wear-resistant materials and easy-access designs for cleaning or replacing components ensures the longevity of the slip ring and keeps maintenance needs to a minimum.

Each of these components and design features plays a significant role in allowing helicopter slip rings to achieve their primary function of facilitating efficient electrical connections within the constantly moving systems of a helicopter. Understanding these aspects can greatly help in the preventative maintenance and troubleshooting of these critical devices.

Helicopter Slip Rings Design Criteria

The design of helicopter slip rings must adhere to specific criteria to ensure they perform reliably under the demanding conditions of helicopter operation. Key design criteria include:

- Electrical Performance:

- Current and Voltage Ratings: Must handle the required current and voltage levels without degradation or excessive heating.

- Signal Integrity: Should maintain the integrity of signals, minimizing electrical noise and crosstalk.

- Power and Signal Transmission: Capable of transmitting both power and various types of signals (analog, digital, RF).

- Mechanical Durability:

- Rotational Speed: Must withstand the high rotational speeds of helicopter components.

- Vibration and Shock Resistance: Designed to endure the significant vibrations and shocks experienced during flight.

- Wear Resistance: Materials used should resist wear and tear to ensure a long operational life.

- Environmental Resistance:

- Temperature Range: Operate effectively within the wide temperature ranges experienced by helicopters, from extreme cold at high altitudes to heat near engines.

- Humidity and Moisture: Must be sealed or treated to prevent failure due to moisture ingress and corrosion.

- Dust and Debris: Should be protected against dust and debris that could interfere with operation.

- Size and Weight:

- Compact Design: Should be as compact and lightweight as possible to minimize impact on helicopter performance and aerodynamics.

- Integration: Easily integrated into the helicopter’s existing systems without requiring extensive modifications.

- Reliability and Maintenance:

- High Reliability: Must have a high mean time between failures (MTBF) to reduce the need for frequent maintenance.

- Ease of Maintenance: Should be designed for easy access and replacement to minimize downtime during maintenance operations.

- Material Selection:

- Conductive Materials: High-quality conductive materials (e.g., gold, silver) for reliable electrical contact.

- Insulating Materials: Durable insulating materials to prevent short circuits and maintain separation between channels.

- Corrosion Resistance: Materials resistant to corrosion to ensure longevity in various environmental conditions.

- Compliance and Standards:

- Aerospace Standards: Must comply with relevant aerospace standards and regulations, such as those set by the FAA or other aviation authorities.

- Safety Standards: Designed to meet safety standards to ensure the overall safety of the helicopter and its occupants.

By adhering to these design criteria, helicopter slip rings can provide reliable and efficient performance, contributing to the safe and effective operation of helicopters.

Helicopter Slip Rings: Features

Helicopter slip rings are designed with several features that optimize their performance and durability. These key features ensure that the slip rings can meet the demanding requirements of modern aviation:

High-performance Materials

The use of high-performance materials in helicopter slip rings enhances their ability to withstand harsh environments and challenging operating conditions. Premium contact materials like gold and silver provide excellent conductivity, while housing materials such as aircraft-grade aluminum or steel offer strength and durability.

Integration with Various Systems

Helicopter slip rings are designed to seamlessly integrate with diverse systems in the aircraft, ensuring compatibility and maintaining the efficient operation of various subsystems and units. From navigation and avionic systems to transmission and rotor control systems, slip rings play a vital role in connecting these subsystems electrically.

Compact and Lightweight Design

Given the limited space available in helicopter designs and the impact of weight on fuel efficiency and flight performance, compact and lightweight slip rings are essential. Their reduced size and weight allow them to be effortlessly integrated into the helicopter, while also reducing overall system weight for optimum performance and fuel efficiency.

High-speed Data Transmission

With today’s complex avionic systems and the necessity for real-time communication and control, helicopter slip rings must deliver high-speed data transmission. Faster data transmission enables a timely and accurate flow of information, allowing pilots and ground personnel to access crucial information promptly and respond to changing flight conditions.

Long Service Life

To achieve long service life, slip rings must be designed to resist wear and tear, optimally maintain electrical connections, and operate effectively in high-speed rotating environments. High-quality materials and protective features ensure longevity, reducing maintenance and replacement costs, and contributing to overall operational efficiency.

By considering each of these essential features, helicopter slip rings have become indispensable components that complement the high-performance, rapidly evolving world of aviation. Their integration into helicopter systems significantly enhances performance, safety, and reliability, making them critical for seamless aircraft operation.

Helicopter Slip Rings: Benefits of Using

The use of slip rings in helicopters comes with a myriad of benefits that are fundamental to the operational efficiency, safety, and overall performance of these aircraft. These benefits include:

Enhanced Reliability and Safety

Helicopter slip rings are crucial for ensuring the reliability of avionic systems by providing a continuous transmission of power and signals. A consistent supply of power to the critical moving parts of a helicopter considerably reduces the risk of system failures, thereby enhancing the safety profile of the aircraft.

Reduced Maintenance and Downtime

With their rugged design and high-quality material composition, helicopter slip rings are designed to resist wear and operate effectively under harsh conditions, thus reducing the need for frequent maintenance. Less maintenance directly translates to less downtime, which eventually increases the helicopter’s operational availability and productivity.

Improved Efficiency and Performance

By ensuring efficient transmission of electrical signals and power, helicopter slip rings play a vital role in optimizing the performance of various systems within the aircraft. Whether it’s enhancing the accuracy of navigation, boosting communication clarity, or ensuring smooth rotor operation, the improved efficiency largely contributes to the overall performance of helicopters.

Minimized Wear and Tear

Thanks to the use of premium contact materials and protective housing, helicopter slip rings are quite resistant to wear and tear, despite being subjected to high-speed rotations and harsh operational conditions. Minimized wear and tear extend their lifespan, minimizing the need for replacements, and reducing operational costs.

Simplified Implementation and Customization

Customization options allow helicopter slip rings to be adapted to the specific requirements of different helicopter models. This flexibility simplifies their implementation into diverse systems, making it easier for engineers and technicians to integrate them into the aircraft.

In summary, the incorporation of slip rings in helicopters offers valuable advantages, underscoring their importance in today’s aviation industry. By facilitating reliable and efficient operations, these components form a crucial part of the systems that keep helicopters safely soaring in the skies.

How Helicopter Slip Rings Work

Helicopter slip rings possess a unique design and functionality that distinguishes them in the field of electromechanical devices. Let’s delve into a detailed explanation of their working mechanism:

The Transmission of Power and Signals

At the very core of their function, helicopter slip rings facilitate the transmission of power and signaling between stationary and rotating parts. They achieve this by ensuring a smooth electrical connection through a series of conductive rings and brushes. Electrical currents or signal inputs enter through the brushes, which maintain continuous contact with the rotating rings – this is how power and signals get transferred.

Rotational Movement and Electrical Connection

Helicopter slip rings are designed to manage high-speed rotational movements while maintaining a steady and uninterrupted electrical connection. The rotor, which is connected to the rotating part of the helicopter, rotates in sync with it. At the same time, the brushes remain stationary, ensuring a continuous electrical connection despite the movement. It’s this unique capability that allows slip rings to enable the smooth function of various systems within the helicopter, from the rotors to communication equipment.

Common Challenges and Solutions

Despite their crucial role, helicopter slip rings face several challenges. Wear and tear can arise due to the constant physical contact between brushes and rings. Also, environmental factors may affect slip ring performance. However, these challenges are tackled via strategic design solutions:

- Design For Wear and Tear: The use of high-quality, wear-resistant materials, and a design that allows for easy maintenance and repair, are critical in ensuring the longevity of the slip rings. Incorporating precious metals that offer high conductivity and low resistance helps to prolong the lifespan of the slip rings.

- Environmental Protection: Housing materials provide protection from external contaminants like dust and moisture, guaranteeing smooth operation in various environments. Sealing and protection features safeguard the slip ring components from potential damage due to harsh operating conditions.

In a nutshell, the competency of helicopter slip rings is anchored on their ability to maintain electrical connections, enabling the transmission of power and signals, even in challenging settings and high-speed rotational conditions. Their design and material choices are crafted to provide solutions to the inherent challenges, ensuring they remain a vital component in the functioning of a helicopter.

Helicopter Slip Rings Power Circuits

Helicopter slip rings are integral to transferring power and signals between stationary and rotating parts of the helicopter. When designing power circuits for these slip rings, several critical factors and considerations must be taken into account:

Key Considerations for Power Circuits in Helicopter Slip Rings

- Current Capacity:

- Load Requirements: The power circuits must handle the maximum current required by all connected devices without overheating or degrading.

- Conductor Size: Adequate conductor cross-sectional area to minimize resistive losses and ensure efficient power transfer.

- Voltage Rating:

- System Voltage: The design must accommodate the voltage levels used in the helicopter’s electrical systems, which could range from low voltage for sensors to higher voltages for power equipment.

- Insulation and Isolation:

- Dielectric Strength: Insulation materials must withstand the system voltage plus a safety margin to prevent breakdown.

- Isolation Between Channels: Effective isolation to prevent cross-talk or short circuits between power and signal channels.

- Contact Materials:

- Conductivity: High conductivity materials like gold or silver are preferred for the contact surfaces to minimize electrical resistance.

- Wear Resistance: Contact materials must resist wear to maintain reliable electrical contact over the slip ring’s operational life.

- Thermal Management:

- Heat Dissipation: The design should include features to dissipate heat generated by the current flow through the slip ring, such as heat sinks or cooling channels.

- Temperature Range: Components should operate reliably within the temperature extremes encountered in helicopter environments.

- Environmental Protection:

- Sealing: Slip rings should be sealed to protect against moisture, dust, and other environmental contaminants.

- Corrosion Resistance: Use of corrosion-resistant materials to ensure longevity in harsh environments.

- Mechanical Considerations:

- Rotation Speed: Bearings and contact assemblies must withstand the rotational speeds typical of helicopter components.

- Vibration and Shock: The design should be robust against vibrations and shocks encountered during flight operations.

Typical Power Circuit Components

- Conductive Rings and Brushes:

- Rings: Typically made of copper or brass with a coating of gold or silver for improved conductivity and reduced wear.

- Brushes: Often made of graphite or precious metal alloys to ensure consistent contact and minimize wear.

- Insulation:

- Barriers: Insulating barriers between rings to prevent short circuits.

- Encapsulation: Some designs use encapsulation materials to protect against environmental factors.

- Connectors and Terminals:

- Connection Points: Reliable connectors for attaching the stationary and rotating parts of the power circuits.

- Wiring: High-quality, aviation-grade wiring to withstand the environmental and mechanical stresses.

- Bearing Assemblies:

- Low-Friction Bearings: To minimize wear and ensure smooth operation.

- Vibration Dampening: Bearings designed to absorb vibrations and shocks.

Circuit Design Examples

- Direct Power Transfer:

- High-Current Circuits: For powering major systems like rotor motors or actuators.

- Low-Current Circuits: For sensors and communication systems requiring less power.

- Integrated Signal and Power Transfer:

- Multiplexed Circuits: Combining power and signal transfer in the same slip ring assembly to reduce space and weight.

By meticulously designing the power circuits of helicopter slip rings with these considerations, manufacturers can ensure reliable performance and long service life under the demanding conditions of helicopter operation.

Helicopter Slip Rings: Maintenance and Troubleshooting

Helicopter slip rings, as crucial components of an aircraft’s operation, require regular maintenance and timely troubleshooting to retain their reliability and performance. Insights into these processes can be instrumental in minimizing downtime and maximizing operational efficiency:

Regular Maintenance and Inspection

Conducting regular and systematic maintenance, involving thorough inspection, cleaning, and, if necessary, replacement of components, helps keep helicopter slip rings in optimal working order. Regular maintenance can detect potential issues early and prevent system failures, thus extending the life of the slip rings. To support this process, aircraft maintenance personnel often follow a detailed checklist and maintenance schedule defined by the manufacturer.

Identifying Common Issues

A key aspect of maintenance is accurately identifying common issues that might impair the performance of the slip rings. Issues might include excessive electrical noise, low signal quality, increased resistance, or physical damage to the slip ring components like erosion of the contact surfaces. Frequent and vigilant checking is necessary to catch these problems before they escalate into major failures.

Troubleshooting Tips and Solutions

Once an issue has been identified, competent troubleshooting is required to rectify it. Many problems can be resolved by simply cleaning the slip rings, as dust and debris accumulation can often be the reason for degraded performance. Contact surfaces should be clear and the continuity of the electrical circuit should be confirmed using testing equipment. Understanding the probable causes for the malfunction, referring to the manufacturer’s guidelines, and applying systematic troubleshooting methods can lead to quick and effective solutions.

When to Replace or Repair a Helicopter Slip Ring

If the identified issue cannot be rectified through cleaning or minor adjustments, a repair or replacement might be necessary. Signs such as persistent noise, repeatedly degraded signal quality, or physical damage are clear indicators of the need for repair. However, when repairs fail to restore the slip ring to its normal functioning state, a replacement becomes the realistic solution.

Maintenance and troubleshooting for helicopter slip rings are crucial processes to prolong their lifespan and uphold their performance. By following regular maintenance schedules, quick problem identification, effective troubleshooting, and knowing when to repair or replace, the operational efficiency and safety of the aircraft can be assured.

Selecting the Right Helicopter Slip Ring

Choosing the right helicopter slip ring is a crucial process that directly influences the aircraft’s performance and safety. Various significant considerations factor into this decision, and it is also invaluable to consult with manufacturers and industry experts.

Considerations for Choosing a Slip Ring

Compatibility: Slip rings must be compatible with the particular helicopter model and system in which they will be integrated. Factors to consider include dimensions, mounting requirements, connections, and voltage or current capacities. Furthermore, the slip ring should meet the performance requirements of the specific applications in the helicopter.

Performance: Performance factors such as rotational speed, the number of circuits, bandwidth, and resistance to vibration and shock must also be addressed. The slip ring should be capable of transmitting the needed power and signals effectively under the operational conditions the helicopter will encounter.

Environmental Factors: The slip ring should be designed to operate effectively under the specific environmental conditions that the helicopter will encounter. These can include altitude, temperature fluctuations, exposure to moisture or dust, and more. The right slip ring for your helicopter will have the necessary protections to operate reliably under these conditions.

Consulting with Manufacturers and Experts: Making the right choice when selecting a helicopter slip ring can be a complex task, and there is no substitute for expertise and experience in this process. Seeking guidance from slip ring manufacturers can be invaluable. Manufacturers possess in-depth knowledge of their products, understand the technical nuances involved, and can provide vital insights that ensure the chosen slip ring meets the specific needs of your helicopter system perfectly.

In conclusion, the selection process of a helicopter slip ring requires taking several critical factors into account. Understanding these factors, along with professional advice from manufacturers and industry experts, can ensure the slip ring’s compatibility with the helicopter and its systems, leading to robust performance and long-lasting reliability.

Have a custom project? Share your details with us and we will contact you soon.

Helicopter Slip Rings Market and Manufacturers

The helicopter slip rings market continually evolves due to the growing demands in the aviation industry. A variety of factors contribute to market growth, and key manufacturers play pivotal roles in meeting these demands. Here, we examine some of the key players in the market, factors influencing growth, and prominent manufacturers and their products.

Key Players in the Market

The helicopter slip rings market comprises numerous players, including manufacturers of slip rings, suppliers of materials and components, and helicopter manufacturers that integrate slip rings into their systems. These players collaborate and compete to develop reliable, innovative, and customized slip rings to cater to the diverse needs of the aviation industry.

Factors Influencing Market Growth

A number of factors contribute to the growth of the helicopter slip rings market:

- Technological Advancements: Continuous advancements in slip ring technology, aiming to improve efficiency, reduce wear and tear, and minimize maintenance costs, drive the market forward.

- Increasing Applications: The growing demand for helicopters across various sectors, including emergency services, tourism, and military applications, leads to a higher demand for slip rings.

- Customization Needs: As helicopters are used for specific purposes and in distinct environments, there is an increasing need for customized slip ring solutions, further expanding the market.

- Safety and Regulatory Requirements: Strict safety and regulatory compliances across the aviation industry necessitate innovations and the use of state-of-the-art technologies in helicopters, fueling the demand for advanced slip rings.

Top Manufacturers and Their Products

Some prominent manufacturers in the helicopter slip rings market include:

| No. | Manufacturer | Website |

|---|---|---|

| 1 | Hangzhou Grand Technology | https://www.grandslipring.com/ |

| 2 | Moog Inc. | https://www.moog.com/ |

| 3 | Stemmann-Technik | https://www.stemmann.com/en/home |

| 4 | Schleifring | https://www.schleifring.com/ |

Hangzhou Grand Technology

Hangzhou Grand Technology Co., Ltd. started as a special slip ring manufacturer in 2011. Grown into slip rings, rotary joints, and slip ring assembly experts of today with 6,000 square meter manufacture complex.

Obtained ISO9001, Rosh, CE, and GJB9001B certificates a number of slip rings, rotary joint patents, and proud of our products can meet military grade. Collaborated with universities, institutes, and renowned factories across Asia and Europe including Panasonic, SIEMENS, CSIC, SAMSUNG, HUAWEI, etc.

Moog Inc.

Moog is a leading supplier of high-performance slip rings for various industries, including aerospace. Among their offerings, Moog’s SR Series Slip Rings are designed for the demanding environments of helicopters, excelling in performance, reliability, and customization potential.

Stemmann-Technik

Stemmann-Technik, a part of the Conductix-Wampfler Group, offers a broad range of slip rings, including solutions for helicopters. Their Livietta Slip Ring Assemblies are designed explicitly for harsh and demanding environments in the aviation sector, providing reliable signal and power transmission.

Schleifring

Schleifring is a well-known manufacturer of electromechanical systems, including slip rings customized for various industries. Their Aircraft Slip Rings cater specifically to helicopters, offering robust performance, low wear, and high reliability to meet the challenges of aviation applications.

If you want to know more about other slip ring manufacturers, you can read Top 10 Slip Ring Manufacturers in China, Top 10 Slip Ring Manufacturers In the USA Market 2023, and Top 10 Slip Ring Industry Key Manufacturers 2023

In summary, the helicopter slip rings market is shaped by multiple players, factors, and technological advancements. Key manufacturers and their products play a critical role in addressing industry demands for high-quality, reliable, and customized slip ring solutions.

Helicopter Slip Rings: Future Developments and Trends

Progress in technology and innovation drastically shape the future path of helicopter slip rings, influencing both their design and manufacturing. This continuous evolution is guided by two main elements: advancements in related technologies and upcoming innovations in slip rings themselves.

The Impact of Technology Advancements

Technology advancements in areas related to helicopter slip rings significantly influence their future developments:

- Material Science: Continuous development in material science may lead to the discovery of newer, more conductive, and durable materials that can be used in slip ring assemblies. The result could be more efficient slip rings capable of withstanding higher rotational speed and greater loads, thereby improving their durability and operational life.

- Resilience to Environmental Stressors: Advancements in sealing and coating technologies could lead to more resilient designs capable of withstanding harsh environmental conditions, thus minimizing failures due to environmental stressors like moisture, dust, and extreme temperatures.

- Data Transmission: The trend toward data-driven operations in helicopters creates a demand for slip rings capable of handling higher bandwidths and transmission rates. Advances in technology therefore hold the promise of slip rings that can handle more data and operate at higher speeds.

Upcoming Innovations in Helicopter Slip Rings

The industry is constantly seeking innovative ways to improve the performance, reliability, and lifespan of helicopter slip rings:

- Contactless Technology: Non-contact or wireless slip rings, which use electromagnetic or optical means to transmit power and signals, are an emerging innovation. They could potentially eliminate the wear and tear associated with physical contact in conventional slip rings, significantly enhancing longevity and reducing maintenance.

- Miniaturization: As helicopters incorporate more advanced technology, the demand for smaller, lighter components grows. Thus, there is an escalating trend toward the miniaturization of slip rings, ensuring the provision of the functionality required without taking up precious real estate within the helicopter.

- Integrated Smart Sensors: The incorporation of smart sensors into slip rings may allow real-time monitoring of their operational parameters, enabling predictive maintenance and enhancing reliability.

The future trends in helicopter slip rings are likely to be dominated by these technological advancements and innovations. The ability to anticipate and leverage these trends will be pivotal for manufacturers, ultimately leading to safer, more efficient, and reliable helicopters.

Conclusion

Helicopter slip rings, an integral component of rotorcraft machinery, are decisive in enabling the transfer of electrical signals and power from the stationary to rotating parts of the aircraft. In this thorough exploration, we have covered various facets related to their design, functionality, maintenance, selection procedures, market trends, and future projections.

Recap of Key Points Discussed

We have emphasized that the essence of a slip ring lies in its ability to ensure seamless communication between the static and rotary parts of a helicopter. An impeccable design and careful selection based on compatibility, performance, and environmental factors are vital. Regular maintenance and apt troubleshooting techniques are key to the longevity and efficacy of these components. Also crucial is an understanding of the market dynamics – acknowledging the critical role of manufacturers and staying abreast of the factors influencing market growth. Looking towards the future, we should anticipate and prepare for the impact of technological advancements and upcoming innovations in slip ring technology.

The Significance of Helicopter Slip Rings in the Aviation Industry

The critical role that slips rings play in the operation of helicopters and their widespread applications signify their importance in the aviation industry. From enhancing operational safety to augmenting communication efficiency, slip rings contribute significantly to the aviation sector. Their function in transmitting power and critical data ensures the smooth running of essential helicopter systems, directly affecting performance and safety.

In conclusion, while often overlooked in favor of more visible components, helicopter slip rings serve a fundamental role in establishing a reliable connection between static and rotating systems, contributing to the safety, functionality, and effectiveness of helicopters. As we move towards a future of increased dependency on aircraft and data-driven operations, these components’ significance will only amplify. Thus, a thorough understanding and continual awareness of their operation, maintenance, market trends, and future developments are indispensable for professionals in the aviation sector.

Want to discuss your slip ring needs? Fill out the form and we’ll reach out to you.

FAQs about Helicopter Slip Rings

Helicopter slip rings are an essential component in modern rotorcraft, facilitating the transmission of electrical power and signals between the stationary and rotating parts of the aircraft. To help clarify their functionality, design, and application, we have compiled a list of frequently asked questions regarding helicopter slip rings.

Q: Why are slip rings important in helicopters?

A: Slip rings contribute significantly to the efficiency, performance, and safety of helicopters. They maintain a consistent flow of power and data between the static and rotating components, enabling reliable communication, control, and monitoring of essential helicopter systems.

Q: How do helicopter slip rings work?

A: Helicopter slip rings feature a series of stationary brushes (typically made from precious metals) that maintain contact with rotating rings. As the rotor turns, these brushes slide over the rings, transferring electrical current and signals between the stationary and rotating parts.

Q: What factors should be considered when selecting a helicopter slip ring?

A: Important factors to consider when selecting a helicopter slip ring include compatibility with the specific helicopter model, performance requirements, environmental factors, and consultation with manufacturers and industry experts. Ensuring proper compatibility, meeting performance demands, and addressing environmental factors leads to optimal performance and reliability.

Q: How often do helicopter slip rings require maintenance?

A: The maintenance frequency for helicopter slip rings depends on factors such as operational hours, environmental conditions, and the slip ring’s design and materials. Regular inspections and maintenance are crucial for ensuring longevity, performance, and safety, with typical intervals ranging from every 100 to 500 flight hours, or as recommended by the manufacturer.

Q: What future developments and trends can we expect in helicopter slip rings?

A: Future trends and developments in helicopter slip rings will likely be driven by advancements in related technologies and innovations in the slip rings themselves. Among the anticipated trends are: the use of advanced materials, increased resilience to environmental stressors, improved data transmission capacities, contactless or wireless slip rings, miniaturization, and the integration of smart sensors for real-time monitoring and predictive maintenance.

Overall, helicopter slip rings play a significant role in ensuring the reliable operation of critical onboard systems, directly influencing efficiency, safety, and performance. Comprehensive knowledge of their design, function, and maintenance, as well as staying informed about market trends and technological advancements, is vital for professionals in the aviation industry.

See What We Can Do