Embark on an exploratory journey as we delve into the intricacies of single-channel slip rings. This guide will navigate you through their basic principles, elaborate on design and construction, unveil common applications, and provide crucial insight into selection, installation, and maintenance. Prepare to address potential challenges and discover innovative trends that are shaping the future of slip ring technology, complemented by practical purchasing advice.

Introduction to Single-Channel Slip Rings

In the realm of mechanical and electrical design, there exists an ingenious solution to a complex problem: How does one reliably transmit power and data across rotating interfaces? The answer lies in the subtle yet robust technology of slip rings. Fundamentally, a slip ring is an electromechanical device that serves the critical purpose of maintaining an electrical connection between stationary and rotating systems. This enables energy or data to transfer seamlessly without hindering the rotating component’s freedom of motion.

Diving deeper into the spectrum of slip rings, we encounter the single-channel slip ring—a specialized variant crafted for simplicity and precision. Characterized by its capability to support just one electrical circuit, the single-channel slip ring takes form as a miniature sentinel of signal transfer. Unlike its multi-channel counterparts, designed to handle intricate networks of electrical paths, the single-channel slip ring is streamlined for tasks where one connection suffices. This singular focus underscores its primary use: to provide a trustworthy conduit for power or signal in applications where compact design and reliability are not merely beneficial but essential.

The central role of single-channel slip rings comes to life in diverse applications. The compact cores of CCTV cameras, enable endless panning without cable entanglement. Within the meticulous confines of robotic arms, they assure continuous power supply and sensory feedback while the machinery articulates. Even in the vast spans of wind turbines, the single-channel slip ring finds its place, easing the transfer of power generated from the sweeping blades to the non-moving parts of the structure.

This introductory passage primes us for the subsequent sections, where we shall explore the principles, design, and application of single-channel slip rings in greater detail, stitching together a coherent and comprehensive understanding of this pivotal technological staple.

Basic Principles of Single-Channel Slip Rings

The engineering community’s perpetual quest to marry motion with connectivity has led to the bespoken elegance of single-channel slip rings, whose operation hinges on a beautifully orchestrated dance of static and dynamic electrical contacts. At its rudimentary core, a single-channel slip ring functions by providing a bridge—a continuous loop—for electricity or data signals to traverse from a stationary platform to a rotating one or vice versa. It accomplishes this through a symphony of two main components: a conductive ring that is free to rotate, typically attached to the rotating part of the application, and a stationary brush, or contact, that maintains an electrical connection with the ring; thus forming a single circuit path.

As the system operates, the rotating ring whirls in unison with the device it serves—a turret, perhaps, or a medical table—while the stationary brush, held in place by an arm or similar mechanism, allows the electrical current or signal to flow continuously even as the device rotates. The brush is crafted with precision and care, fashioned from materials that not only conduct electricity but also display endurance against the physical demands of persistent rubbing against the rotating ring. Consequently, the single-channel slip ring stands as an unceasing guardian of electrical continuity, allowing the mechanism it empowers to rotate infinitely without a tether that would otherwise restrict movement or become entangled.

Equally important is the role single-channel slip rings play in signal transmission. They are not mere carriers of raw power; they are the arteries of data, the messengers that enable sensors and control systems on rotating platforms to communicate with the rest of the equipment. With technological advancement, the signals have evolved from mere electric currents to encompass sophisticated digital data. Thus, the single-channel slip ring must execute its task with minimal interference and utmost fidelity, ensuring that the integrity of the transmitted data remains pristine and uncorrupted by electrical noise or potential wear over time.

This fundamental understanding of how single-channel slip rings work and their crucial role in maintaining both power and signal integrity sets the stage for appreciating their nuanced design and construction, which we will explore next, thus unraveling the complexities behind their seemingly simple function.

Single-Channel Slip Rings: Design and Construction

The architectural finesse of single-channel slip rings is a testament to the marriage between mechanical ingenuity and electrical engineering, manifesting in a device that’s both compact and profoundly capable. Delving into the design and construction of these devices unveils a harmony of components, each selected for its role in ensuring uninterrupted electrical continuity and signal integrity across rotating interfaces. Central to this assembly is the housing, the conductive ring, the brush, and the insulation materials—each integral to the slip ring’s function and reliability.

Housing: Serving as the protective shell, the housing encapsulates the inner workings of the slip ring. It is more than a mere container; it is crafted to withstand environmental adversities—be it dust, moisture, or varying temperatures—while maintaining structural integrity. Materials such as aluminum alloys or engineered plastics are favored for their balance of strength, lightweight characteristics, and electromagnetic shielding capabilities, thus safeguarding the electrical components nestled within.

Conductive Rings and Brushes: At the heart of a single-channel slip ring lies the conductive ring, a path of electrical conduction that rotates in tandem with the application it serves. The ring’s counterpart, a stationary brush or contact, maintains a persistent electrical connection with this rotating ring. This duo forms the essential circuit path over which power or signals flow. Materials play a pivotal role here; the conductive rings are often made from copper or copper alloys, prized for their excellent electrical conductivity and wear resistance. The brushes, on the other hand, might be crafted from graphite or precious metal alloys like silver or gold, selected for their low electrical resistance, minimal contact noise, and resilience against physical wear over repeated rotations.

Insulation Materials: Ensuring that the electrical charge is directed solely along the intended paths requires high-quality insulation materials. These materials prevent electrical leakage and ensure that the device operates safely and efficiently. Polymers such as PTFE (Teflon) or polyimide are commonly employed due to their high dielectric strength, thermal stability, and resistance to chemical and environmental degradation. The choice of insulation is critical, especially in applications where the slip ring must perform under extreme conditions or near sensitive electronic equipment.

Bearings and Seals: Supporting the rotating assembly and ensuring smooth, long-lasting operation, bearings are fundamental to the slip ring’s design. Precision-engineered ball bearings or sleeve bearings are selected based on the expected rotational speed and load. Seals complement the bearings by protecting the internal components from ingress of contaminants and moisture, aiding in the slip ring’s durability and performance reliability.

The confluence of these components, each chosen for its performance characteristics and harmonized into the single-channel slip ring’s compact design, underscores the sophistication behind this seemingly straightforward device. This careful selection and integration of materials not only fortify the slip ring against the physical and electrical challenges of its operating environment but also imbue it with the reliability and efficiency required for its critical role in uninterrupted power and signal transmission in a myriad of applications.

Applications of Single-Channel Slip Rings

The remarkable agenda of single-channel slip rings reveals sprawling versatility that extends into an array of sectors. Their constrained size, uncompromised reliability, and proficiency in managing power and data in the rotating interfaces place them at the core of diverse applications. Let’s traverse key industries and machinery where these nimble players shine, appreciating the unique benefits they bring to the fore.

Security and Surveillance: In this rapidly advancing sector, single-channel slip rings form an integral part of Closed-Circuit Television (CCTV) cameras, enabling uninterrupted 360-degree surveillance. Installed in the base of the camera, these slip rings allow for continuous rotation, thus eliminating blind spots often associated with traditional camera setups.

Telecommunications: Single-channel slip rings feature in satellite dish antenna motors where precision and consistent power supply are par for the course. They ensure smooth and continuous rotation of the dish, and seamless data transmission, thereby optimizing received signal strength and quality.

Renewable Energy: Despite their small stature, single-channel slip rings contribute significantly toward renewable energy pursuits, particularly wind energy. Installed in wind turbines, they facilitate the transfer of generated power from the constantly spinning blades to the stationary grid, ensuring efficient energy output and system performance.

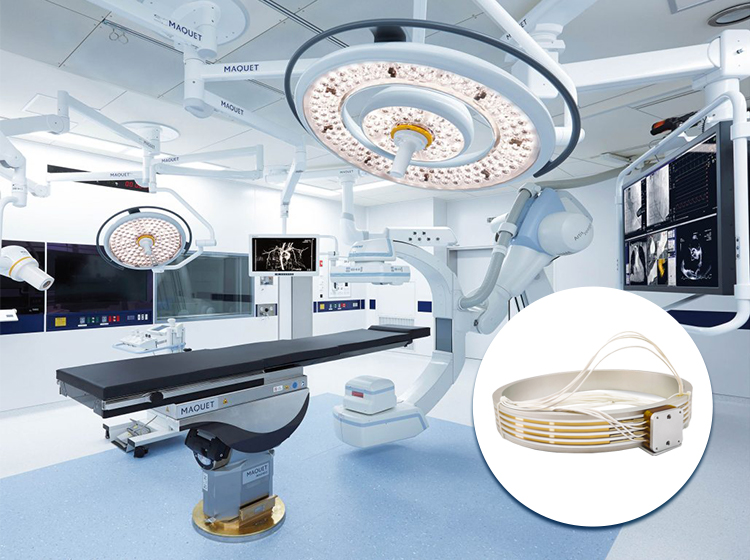

Medical Equipment: The realm of medical technologies also witnesses these slip rings’ adaptability. In magnetic resonance imaging (MRI) scanners, single-channel slip rings aid non-stop rotation of the scan elements, fostering high-fidelity data transfer that results in clearer, more accurate images for diagnosis.

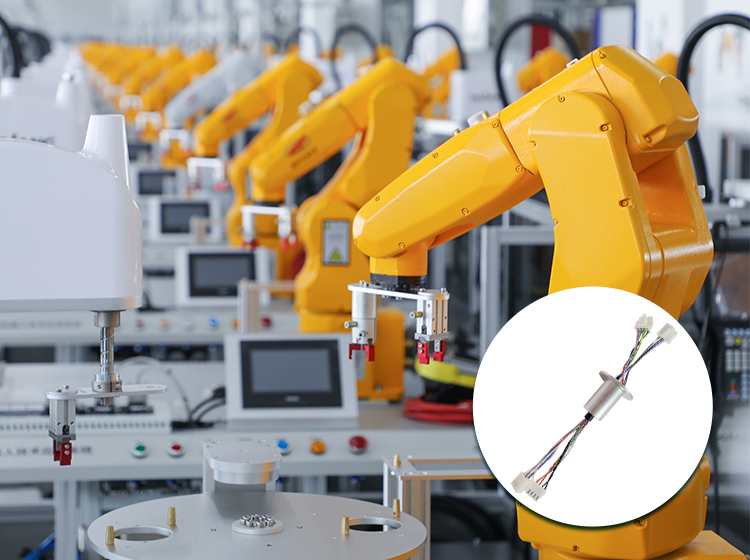

Industrial Automation and Robotics: In robotic arms and automated assembly lines, single-channel slip rings deliver dependable power and transduce feedback signals, coordinating compositions, allowing for articulate movement, delicate processing, and refined control.

Marine Equipment: Dive into the marine industry, and single-channel slip rings emerge within rotating sonar systems or surveillance equipment. These slip rings navigate corrosive effects and high-pressure environments, ensuring durable performance and data integrity beneath the waves.

Embracing single-channel slip rings in these applications usher in a plethora of benefits. They execute their task with minimal interference and optimum fidelity, ensuring that the power supply and signal integrity remain unaffected by the device’s rotational movement. Compact and lightweight, they effortlessly fit into tight spaces, providing an ideal solution in modern miniaturized designs without compromising performance. By ensuring seamless rotation and facilitating a ring–to–bush interface instead of cable connections, they defy the challenges of cable tangling, stretching, and wear, maintaining a clean and continuous connection.

Each industry is testimony to the fact that single-channel slip rings are more than just their construction elements. While they might seem to be simple devices, they function as crucial cogs in machines that directly and indirectly touch our daily lives, from home security to renewable energy and medical diagnostics to industrial processes. This reiterates the importance of understanding and appreciating their selection, installation, and maintenance, to ensure they function at their finest, always delivering the benefits they promise.

Single-Channel Slip Rings: Selection Criteria

The process of selecting an appropriate single-channel slip ring goes beyond a cursory glance at its exterior; it dives deep into a comprehensive understanding of its operational parameters and the environment it’s destined to thrive. Whether for an industrial giant, a delicate medical device, or a state-of-the-art communication system, the selection of a slip ring is a nuanced process that determines the efficiency, longevity, and reliability of the application it serves. Key factors come into play, shaping the decision matrix.

Current and Voltage Ratings: At the forefront of selection criteria are the current and voltage requirements of the application. These parameters define the electrical capacity of the slip ring and ensure compatibility with the system’s power demands. Selecting a slip ring with inadequate ratings could lead to performance degradation or, worse, failure of the system under peak loads. Conversely, vastly oversizing may unnecessarily increase costs. Hence, a keen balance tailored to the specific needs of the application is paramount.

Size and Physical Configuration: The compact environments in which single-channel slip rings are often embedded necessitate meticulous consideration of their size and form factor. The dimensions of the slip ring must harmonize with the available space, ensuring a seamless fit without impinging on the operation of neighboring components. This selection criterion extends to the ring’s design—whether a flat, through-hole, or capsule type—each catering to different spatial arrangements and rotational requirements.

Environmental Conditions: Single-channel slip rings operate across a broad spectrum of environments, from the serene interiors of medical equipment to the tumultuous conditions of marine apparatus. Recognizing the environmental exigencies—such as temperature extremes, moisture, dust, and potential exposure to corrosive agents—is crucial. This recognition informs the selection of appropriate materials for the housing, rings, and insulation, ensuring the slip ring’s resilience and uninterrupted performance under its operating conditions.

Signal Integrity and Noise Considerations: For applications where data transmission is as critical as power supply, considerations extend to signal integrity and electromagnetic compatibility (EMC). The slip ring must safeguard against signal attenuation and electromagnetic interference, which could compromise data accuracy or induce operational anomalies in sensitive electronics nearby. This criterion underscores the relevance of internal shielding, contact material selection, and precise engineering to mitigate noise and uphold signal fidelity.

Understanding Operational Requirements: Beyond the tactile aspects of selection lies the profound importance of understanding the operational narrative of the slip ring within the application. This comprehension encompasses rotational speed, life expectancy (measured in cycles or hours), and maintenance accessibility, alongside the electro-mechanical specifications. A thorough investigation into these operational nuances ensures that the selected slip ring not only fits from a technical standpoint but also aligns with the application’s lifecycle and service regime, optimizing cost-effectiveness and reliability over its tenure.

This detailed selection criteria matrix, therefore, serves as both a guide and a testament to the pivotal role of single-channel slip rings in bridging the divide between static and rotating electrical interfaces. Embarking on the selection process with a holistic view of these criteria ensures that engineers and designers can tailor their choices to match the intricate demands of their applications, securing a harmonious balance between technological aspiration and operational ground realities.

Single-Channel Slip Rings: Installation and Maintenance

Just as an artist meticulously arranges a model for the perfect stroke, so too must single-channel slip rings be delicately mounted and maintained to achieve optimum performance. Implementation of best practices during installation can significantly dictate the slip ring’s longevity, reliability, and overall performance. Beyond this phase, diligent maintenance aligns with the slip ring’s optimum lifecycle, minimizing downtime and mitigating risks of premature failure.

Installation Best Practices:

- Know Your Manual: Familiarize yourself with the manufacturer’s installation guide. Cross-references between these guidelines and your application’s specifications are essential to ensure compatibility and prevent mishaps during installation.

- Environment Preparation: Before installation, validate the slip ring’s surrounding environment. Ensure it exhibits minimal dust, moisture, and temperature fluctuations that may impede the performance or longevity of the slip ring.

- Proper Mounting: When mounting the slip ring, ensure that its alignment is precise and that the rotational interfaces are smooth to prevent undue wear and tear and allow for efficient operation. Exercise care not to over-torque fastening elements, as this can deform the housing and constrain the rotation.

- Effective Cable Routing: The cables connected to the slip ring should be ideally routed to prevent tangling, crossing, and stretching. Proper orientation mitigates risks associated with mechanical stress and inadvertent disconnections.

- System Testing: Following installation, perform an initial system check to verify the operational efficacy of the slip ring within the broader environment. This safeguards against potential issues, allowing for early rectification.

Maintenance Tips:

- Scheduled Inspections: Organize regular inspections of the slip ring and its environment. Look out for signs of wear and tear, condensation, dust accumulation, or any discrepancies that may indicate looming issues.

- Brush and Contact Cleaning: Clean brushes and contacts to prevent the build-up of dust or debris that might compromise the electrical connection. Use a soft cloth or designated cleaning solution, taking care not to damage these sensitive components.

- Electrical Checks: Regularly monitor voltage drops and increases in electrical noise as these might suggest the onset of wear or impending failure.

- Lubrication: If bearings are exposed and not sealed, periodically apply the recommended lubrication to ensure smooth, frictionless rotation.

Taking on installation and maintenance with the best practices in mind amplifies the extent to which the single-channel slip ring can comfortably meet or exceed its expected lifespan. It fosters a symbiosis between the slip ring and its environment, promoting efficient operation while reducing downtimes. Through this vigilant approach to care, the humble single-channel slip ring continues to deftly sustain its crucial role within applications, presenting a testament to the effective amalgamation of meticulous engineering and thoughtful stewardship.

Single-Channel Slip Rings: Challenges and Solutions

In the intricate dance of maintaining continuous electrical connectivity amidst rotational motion, single-channel slip rings emerge as vital components. However, like all marvels of engineering, they’re not without their foibles. Encountering wear and tear, noise, and signal interference is akin to confronting inevitable hurdles on a racetrack. These challenges, if left unchecked, can significantly detract from their performance and durability. Yet, with every problem arises a solution, a pathway to not only confront these challenges but to preemptively shield against them, ensuring the seamless symphony of machine operation continues unabated.

Common Issues Encountered:

- Wear and Tear: Arguably the most prevalent challenge, resulting from the physical contact between the brush and the ring. Over time, this friction leads to material degradation, potentially compromising electrical connectivity and necessitating replacements.

- Electrical Noise: As electrical signals traverse the contact point, disturbances or “noise” might be introduced, possibly due to imperfect contact surfaces, leading to signal degradation or erroneous outputs.

- Signal Interference: In environments rich in electrical and magnetic fields, slip rings can suffer from signal interference, which can distort or interrupt the integrity of the data being transmitted.

Potential Solutions and Preventive Measures:

- Material Innovation: One of the frontier solutions to wear and tear involves the exploration and adoption of new materials in the construction of both the brush and the ring. Silver alloy contacts, for instance, offer a commendable balance between conductivity and durability. Additionally, the inclusion of materials with self-lubricating properties can reduce friction and, by extension, wear.

- Shielding Techniques: To counteract electrical noise and signal interference, implementing shielding techniques around the slip ring assembly is advisable. Encasing the slip ring in a conductive enclosure can significantly inhibit the penetration of external electromagnetic noise. Further, ensuring that the design supports optimal contact pressure between the brush and the ring assists in minimizing intrinsic noise generated by the contact itself.

- Regular Calibration: Instituting a routine of regular check-ups and calibrations aids in the early detection of wear and preemptive corrections. This can involve adjustments to contact pressure or the replacement of components showing significant wear.

- Design Considerations: Embracing design innovations focused on minimizing wear and enhancing signal integrity is crucial. For instance, incorporating multiple points of contact can distribute the wear evenly, thereby extending the lifespan. Additionally, utilizing designs that facilitate easy access to wear-prone components can simplify maintenance and replacement processes.

- Environment Control: Since the operating environment can exacerbate wear and noise, controlling environmental factors such as humidity, temperature, and exposure to corrosive substances can significantly mitigate these issues. Utilizing environmental seals or operating in controlled environments helps preserve the integrity of the slip ring.

By acknowledging the challenges inherent to single-channel slip rings and implementing a robust regimen of solutions and preventative measures, we can not only extend the operational lifespan of these pivotal components but also enhance the overall reliability and efficiency of the systems they empower. It’s a testament to the resilience bred through innovation — a narrative that finds engineers and technicians as the protagonists, constantly adapting and overcoming in the quest to maintain the seamless flow of power and data across the dynamic divide.

Single-Channel Slip Rings: Innovations and Future Trends

The ever-evolving arena of electrical and mechanical engineering is a testament to human ingenuity, pushing boundaries and breaking barriers. Single-channel slip rings, in their pivotal role of maintaining electrical continuity in rotating systems, haven’t been left behind. They’ve experienced a wave of innovations that have redefined their capabilities and expanded their application horizons. Looking ahead, a forecast of future advancements promises further enhancement, tailoring these components to the demands of tomorrow’s applications.

Recent Advancements in Single-Channel Slip Ring Technology:

- Contact Material Development: New materials like precious metal alloys and graphitic compounds have been introduced to create contact surfaces. These offer greater durability, improved electrical conductivity, lower friction, and less generation of debris.

- Wireless Slip Rings: Wireless energy transmission is being explored for rotational systems, using magnetic resonance or radio waves, thus eliminating physical wear and extending lifespan considerably.

- Fibre Optic Rotary Joints (FORJs): In data-rich environments, traditional electrical contacts might struggle with data transmission speed and integrity. FORJs have emerged as an answer, offering a virtually limitless bandwidth with minimal cross-talk and interference.

Future Trends That Could Influence Design and Application:

- Miniaturization: With the continued trend toward miniaturization in electronics, there’s an ongoing race to develop smaller, more compact slip rings with high performance. Nano-scale slip rings could be a future development, paving the way for use in micro-machines or robotics.

- Harsher Environment Adaptability: As we push boundaries with machines, slip rings that can function in harsher environments—extreme temperatures, corrosive environments, or intense electromagnetic fields—are expected to be a growing trend.

- More Channels and Hybrid Solutions: Multifunctional systems demanding power, signal, and high-frequency data transmissions could drive the development of multi-channel or hybrid slip rings, blending electrical, fiber-optic, and wireless technology.

- Smart Slip Rings: Future slip rings could integrate smart elements to monitor performance parameters like wear, temperature, and contact pressure, flagging preventative maintenance and reducing downtime.

The continuous innovations characterizing single-channel slip rings encapsulate the breadth of human creativity and adaptability. As we peer into the future, there’s a sense of confidence that slip rings, in their simplicity, will continue evolving. They’ll adopt advanced materials, leverage wireless technology, and shrink to hitherto unheard-of dimensions to meet tomorrow’s demands. The history of slip rings is still being written, and like any exciting narrative, it’s the novelty of the next chapter that keeps us anxiously anticipating.

Single-Channel Slip Rings: Purchasing Considerations

The journey of procuring a single-channel slip ring extends beyond a mere transaction. It’s about fostering a partnership with a manufacturer or supplier who understands the criticality of your application and is committed to providing a solution that stands the test of time. This process, when navigated thoughtfully, ensures not just the acquisition of a component but the securing of reliability, performance, and support throughout the product’s lifecycle. Hence, vetting manufacturers and suppliers, alongside weighing the importance of warranties and technical support, emerges as a pivotal aspect of the procurement process.

Vetting Manufacturers and Suppliers:

- Manufacturing Expertise and Reputation: Begin with an assessment of the manufacturer’s or supplier’s expertise and reputation in the industry. This involves researching their history, understanding their position in the market, and reviewing feedback or testimonials from past customers. The tenure and breadth of experience in manufacturing slip rings can significantly influence product quality and innovation.

- Quality Certifications: Look for certifications such as ISO 9001, which indicates a commitment to quality management practices. Certifications can serve as a benchmark for the reliability and durability of the products offered.

- Customization Capabilities: Given the diversity of applications, the ability of a supplier to customize slip rings to meet specific operational needs is invaluable. Evaluate their willingness and capability to design solutions tailored to unique requirements.

- Compliance with Standards: Ensure that the products comply with relevant industrial or international standards, which can be crucial for applications in certain sectors, like aerospace, healthcare, or defense.

The Importance of Warranties and Technical Support:

- Warranty Coverage: A comprehensive warranty serves as a testament to the confidence a manufacturer has in their product. It offers a safety net, ensuring that should the product fail within the specified period, support is readily available. The terms of the warranty, including its duration and what it covers, can significantly impact the total cost of ownership.

- Accessible Technical Support: The availability of technical support can be the linchpin in rapidly resolving operational challenges, and minimizing downtime. Look for suppliers who offer robust technical support, preferably with multiple channels for assistance (e.g., phone, email, live chat).

- Training and Documentation: Adequate training materials and documentation are indispensable for installation, operation, and troubleshooting. Providers that supply comprehensive manuals, videos, or even on-site training sessions demonstrate an investment in client success.

As the technological landscape evolves, so too do the parameters guiding the selection of components like single-channel slip rings. Recognizing the importance of a meticulous vetting process places organizations in a position not just to purchase but to invest in solutions that align with present requirements and future ambitions. This approach ensures the endurance of performance, innovation in the application, and the satisfaction of seeing complex systems operate with seamless efficiency, empowered by a humble yet crucial slip ring at their core.

Conclusion

Understanding the gamut of factors associated with single-channel slip rings equips professionals to make informed choices, ensuring that these pivotal components align with the functional prowess of their rotational machinery.

FAQs about Single-Channel Slip Rings

Q: How does environmental temperature affect single-channel slip rings?

A: Temperature variations can impact slip ring performance, necessitating the choice of materials and designs resilient to such changes.

Q: Can single-channel slip rings be used for data transmission?

A: Absolutely, with the provision they are meticulously engineered to preserve signal integrity and minimize noise.

Q: Are there any special considerations for slip rings in medical devices?

A: Indeed, medical applications often require stringent electromagnetic compatibility (EMC) standards, which must be factored into the slip ring design.

Q: What is a single-channel slip ring and what is it used for?

A: A single-channel slip ring is a device used to transmit power or data from a stationary component to a rotating one within a system. Due to its capability to maintain electrical continuity amidst rotation, it’s widely used across various industries like aerospace, wind energy, medical devices, radar, and automation.

Q: What’s the difference between a single-channel and multi-channel slip ring?

A: The key distinction lies in the number of independent electrical circuits each can handle. While a single-channel slip ring caters to one separate electrical circuit, multi-channel slip rings can manage multiple circuits simultaneously, permitting the transmission of several separate signals or power sources.

Q: How long does a single-channel slip ring last?

A: The lifespan of a slip ring is dependent on numerous factors such as the application, operating environment, usage frequency, and maintenance practices. That said, with regular maintenance and adherence to operating instructions, a slip ring can typically offer several million rotations.

Q: Can a slip ring transfer data as well as power?

A: Absolutely! A slip ring can transmit both electrical power and data signals. However, when both are being transmitted through the same circuit, measures must be taken to prevent power-induced interference with the data signal.

Q: How do I maintain a single-channel slip ring?

A: Regular inspection to check for wear and debris is key, as is maintaining the recommended operating conditions (temperature, humidity, etc.). Many slip rings require a specialized cleaning procedure—refer to the manufacturer’s protocol. Remember, non-maintenance can lead to premature wear and subsequent failure.

Q: Can I use a slip ring in a high-vibration environment?

A: While slip rings are generally robust, excessive vibration can cause premature wear and potential failure. Consult with the manufacturer regarding suitable models for such environments, as some slip rings are specifically designed to withstand high-vibration conditions.

See What We Can Do