This article serves as an in-depth exploration of one of the most ubiquitous yet often overlooked components of the modern technological landscape: the squirrel cage electric motor. Designed to be both engaging and informative, we delve into the inherent complexities behind its simple facade, break down its working principles, and address the nuances that make this motor type a backbone of both domestic and industrial applications.

Introduction to Squirrel Cage Electric Motors

Electric motors play a pivotal role in our daily lives, powering everything from household appliances to industrial machinery. Among the various types of motors available, the squirrel cage electric motor stands out for its simplicity, efficiency, and durability. This section delves into the captivating history and development of squirrel cage motors, explains their basic operating principle, and highlights their importance and common applications in modern technology.

A Glimpse into History and Development

The journey of the squirrel cage electric motor began in the late 19th century, amidst a period of rapid technological innovation. The invention is often credited to Nikola Tesla, who introduced the concept of a rotating magnetic field in 1888. Tesla’s groundbreaking work paved the way for the development of the induction motor, which would eventually evolve into the modern squirrel cage motor.

Over the decades, these motors have undergone significant refinement and optimization, driven by advances in materials science and electrical engineering. From the early designs that powered the first electrically driven machines to today’s high-efficiency models used in sophisticated applications, the evolution of squirrel cage motors is a testament to the ingenuity and perseverance of engineers and scientists.

Understanding the Basic Principle of Operation

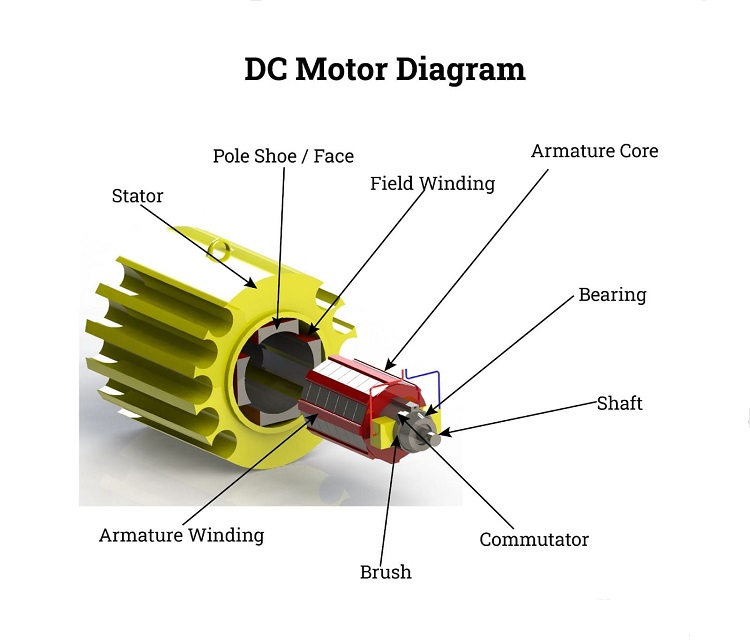

At its core, the operation of a squirrel cage electric motor relies on electromagnetic induction, a phenomenon discovered by Michael Faraday in the early 19th century. The motor consists of two main parts: the stator, which is the stationary outer part, and the rotor, which is the inner part that rotates.

When alternating current (AC) flows through the stator’s winding, it generates a rotating magnetic field. This magnetic field cuts across the conductor bars of the rotor (shaped like a cage, hence the name), inducing an electric current in them due to electromagnetic induction. The interaction between the rotating magnetic field and the induced currents in the rotor produces a force that causes the rotor to turn.

This elegant interplay of magnetic fields and induced currents allows the squirrel cage motor to convert electrical energy into mechanical energy, propelling everything from fans and pumps to conveyor belts and beyond.

The Pillar of Modern Technology: Importance and Common Applications

Squirrel cage electric motors have become indispensable in various sectors due to their reliability, low maintenance requirements, and high efficiency. In households, these motors are the unseen force behind refrigerators, washing machines, and air conditioners, making everyday life more convenient and comfortable.

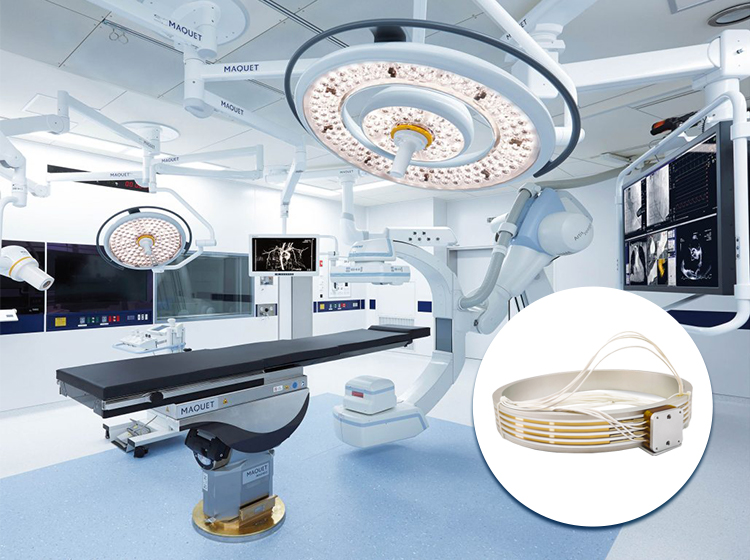

In the industrial realm, squirrel cage motors drive an array of machinery, including compressors, grinders, and assembly line equipment, playing a critical role in manufacturing processes. Moreover, their adaptability makes them suitable for applications ranging from delicate medical equipment to rugged mining operations.

The adoption of squirrel cage motors in renewable energy, particularly in wind turbines, underscores their contribution to sustainable development. By transforming wind energy into electricity, these motors help mitigate reliance on fossil fuels and reduce greenhouse gas emissions.

From their historical roots to their widespread contemporary use, squirrel cage electric motors represent a remarkable convergence of scientific discovery and practical application. Their development over the years has mirrored humanity’s progress, driving innovations that enhance our quality of life. Understanding their operation, appreciating their importance, and recognizing their applications allows us to acknowledge the silent yet profound impact these motors have on our world.

The Anatomy of a Squirrel Cage Electric Motor

To comprehend how squirrel cage electric motors have carved their niche in both industrial and domestic spheres, it’s essential to dissect their anatomy and understand the role of each component. This section delves into the main components of a squirrel cage electric motor, outlines their functions, and contrasts the squirrel cage rotor with other types of rotors.

Peeling Back the Layers: Components and Their Functions

At first glance, the robust exterior of a squirrel cage motor belies the intricate interplay of components hidden within. Let us peel back these layers to reveal the core components and their pivotal roles.

The Stator: The Heartbeat of the Motor

Imagine the stator as the conductor of an orchestra, directing the flow of electrical energy to create a harmonious symphony of movements. It’s the stationary part of the motor, consisting of windings of insulated wire, typically copper, coiled around iron cores. When AC power is applied, these windings generate a rotating magnetic field, the invisible force that sets the motor in motion. The stator’s design is crucial for efficient energy conversion, influencing the motor’s performance, power output, and efficiency.

The Squirrel Cage Rotor: Where Magic Happens

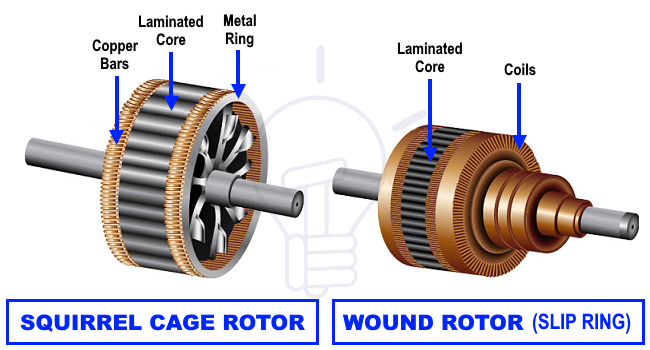

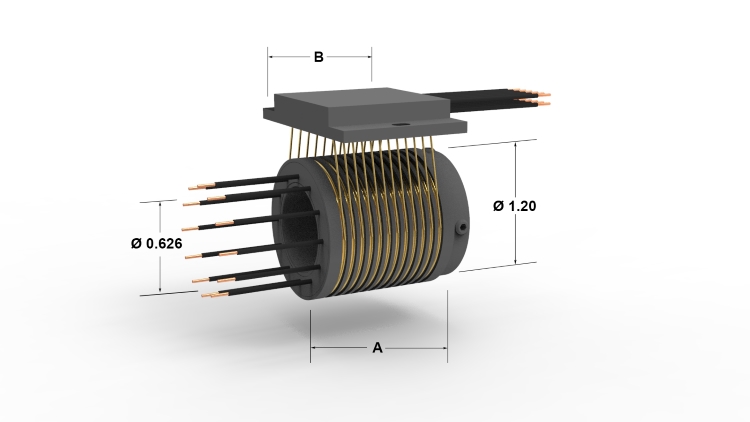

At the heart of the motor lies its rotor, named for its resemblance to a running wheel in a squirrel cage. Made from a series of conductive bars (aluminum or copper) laid parallel to each other and connected at both ends by metal rings, this ingenious design turns electromagnetic principles into physical motion. When the rotating magnetic field generated by the stator sweeps past the rotor bars, it induces an electrical current, which, in turn, produces a magnetic field. This magnetic interaction between the rotor and stator generates the force that spins the rotor, transforming electrical energy into mechanical energy.

End Rings and Bearings: Keeping Everything in Motion

Ensuring the rotor spins smoothly without wobbling or friction are the end rings and bearings. The end rings, typically made from the same material as the rotor bars, ensure electrical continuity, allowing current to flow freely across the rotor bars. Meanwhile, bearings support the rotor’s shaft at either end, minimizing friction and wear during operation. These components are critical for the longevity and reliability of the motor, allowing it to perform seamlessly across various applications.

Beyond the Cage: Comparison with Other Types of Rotors

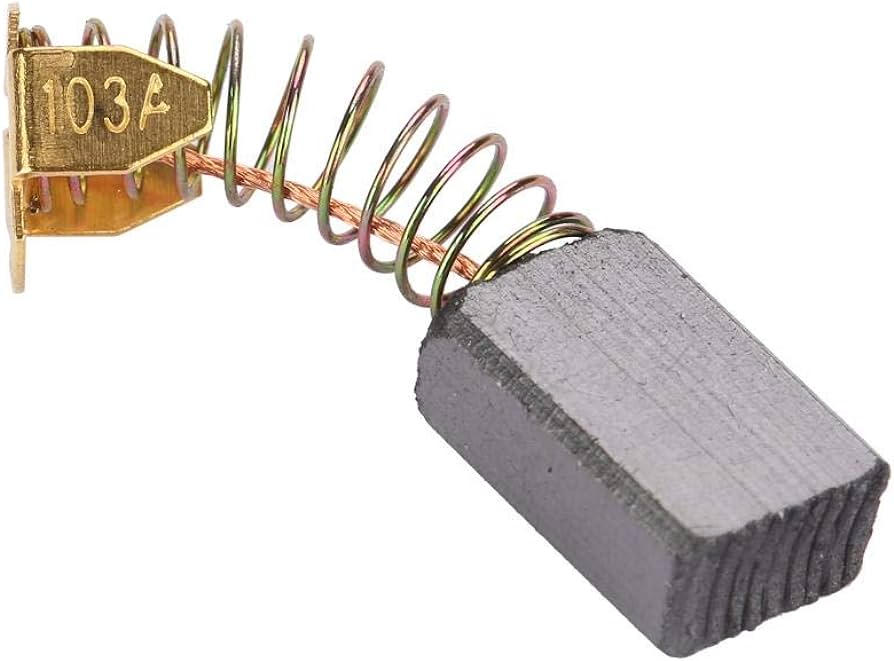

The simplicity and robustness of the squirrel cage rotor set it apart from its cousins, such as the wound rotor used in slip ring motors. Unlike the squirrel cage rotor, wound rotors consist of windings connected to external resistors through slip rings. This design allows for control over the motor’s speed and torque but at the expense of complexity, higher maintenance, and increased cost. The squirrel cage motor, by contrast, boasts a maintenance-free design and efficient operation, making it a first choice for a broad spectrum of uses, from heavy industrial machines to household appliances.

The Role of Innovation in Rotor Design

As technology progresses, so too does the design and material selection for squirrel cage rotors. Innovations like die-cast copper rotor bars are enhancing efficiency, leading to motors that are not only more powerful but also more energy-efficient and less impactful on the environment.

A Testament to Engineering Elegance

The design of the squirrel cage electric motor is an exemplar of engineering elegance, turning fundamental scientific principles into the practical, everyday magic of motion. Its components, each with a critical role, work in concert to offer a seamlessly efficient performance. As we advance, the relentless pursuit of innovation continues to ensure these motors meet the evolving demands of modern industrial and domestic applications. Understanding the anatomy of these motors not only satisfies our curiosity but also deepens our appreciation for the ubiquitous machines that power our world.

How Does a Squirrel Cage Electric Motor Work?

The operation of a squirrel cage electric motor might seem mysterious at first glance. Yet, when we peel back the layers, we uncover a mesmerizing orchestra of electromagnetic principles, alternating currents, and torque production, all working in harmony to create mechanical motion. This section aims to make these complex concepts accessible, explaining their interplay and highlighting their significance in enabling the smooth operation of the motor.

The Invisible Hand: Electromagnetic Principle Behind Its Operation

At the heart of a squirrel cage electric motor lies electromagnetic induction, a concept first discovered by English scientist Michael Faraday in 1831. This principle states that a change in a magnetic field within a closed loop of wire induces an electric current within the wire.

In the context of our motor, when alternating current flows through the stator windings, it generates a rotating magnetic field. This magnetic field sweeps across the rotor bars, inducing electric current within them thanks to Faraday’s principle. The induced current creates its magnetic field, which interacts with the stator’s rotating field. This magnetic interaction exerts a force on the rotor, causing it to turn – a literal translation of electromagnetic principle into physical motion.

The Role of Alternating Current (AC) in Producing Rotational Motion

Alternating Current (AC), the type of electric current delivered to most homes and businesses, plays a pivotal role in squirrel cage motors. AC garnered its name from the way the electric current oscillates, or alternates, its direction periodically between forward and reverse.

This characteristic is crucial in generating the rotating magnetic field within the stator. When AC flows through the stator windings, it causes the magnetic field to rotate because of the change in the direction of the current. This rotating field is key to the operation of the motor, as it induces current within the rotor and creates the forces needed to turn the rotor, resulting in the rotational motion we see in the ever-spinning motor shaft.

Demystifying Torque: A Layman’s Explanation

Torque is the turning force that causes the rotor to spin. Think of it as the push you give a child on a swing – the stronger the push, the higher the child swings. Similarly, in a motor, the stronger the interaction between the magnetic fields of the stator and rotor (created by the AC current and electromagnetic induction), the stronger the torque and the faster the rotor spins.

For a more tangible analogy, imagine a large roundabout in a playground. The roundabout is our rotor, and the children pushing it represent the rotating magnetic fields. As more children push in unison (stronger magnetic field interaction), the roundabout spins faster (increased torque). That’s how squirrel cage motors work – they harness the power of electromagnetic forces to produce torque, driving a myriad of machines around us.

The Dance of Physics and Electricity

The operation of a squirrel cage electric motor is a beautiful dance of physics and electricity, combining the principles of electromagnetic induction, alternating current, and torque generation to perform work. This deep dive into the invisibly powerful world of squirrel cage motors underscores the complexity behind their operation and highlights the marvelous efficiency of their design. Understanding how these motors work not only enlightens us about an essential piece of modern machinery but also provides us with the ability to appreciate the marvel that transpires in the machines that power our world.

Advantages of Squirrel Cage Electric Motors

Squirrel cage electric motors, named for their unique rotor design reminiscent of the exercise wheels used by pet rodents, stand out as marvels of engineering efficiency and versatility. These motors offer a plethora of advantages that make them a preferred choice across various sectors, from the simplicity of household appliances to the complexity of heavy industrial machinery. Let’s navigate through these advantages to understand why these motors are so widely adopted.

The Pillars of Reliability and Durability

One of the foremost benefits of squirrel cage electric motors is their exceptional reliability and durability. The simplicity of their design, with fewer moving parts, minimizes mechanical wear and tear, translating to longer life spans. This robustness means they can operate in a range of environmental conditions – from the dusty floors of a milling factory to the humid conditions of a washing machine in your home.

Consider the case of conveyor belts in the manufacturing sector, which operate almost continuously. These belts rely on the steadfastness of squirrel cage motors, which can run 24/7 with minimal downtime. Their ability to endure and perform consistently under such demanding conditions is a testament to their designed resilience.

Cost-Effectiveness and Low Maintenance: A Financial Win

When it comes to industrial or household investments, two critical factors are often considered: initial costs and ongoing maintenance. Squirrel cage motors excel in both arenas. Their straightforward construction not only makes them less expensive to manufacture but also significantly reduces maintenance needs. With no brushes to replace or commutators to repair (components found in other types of electric motors), the owning and operating costs plummet.

For instance, the widespread use of these motors in HVAC systems highlights their cost-effectiveness. Given the high duty cycles of these systems, the low maintenance requirement of squirrel cage motors provides a significant reduction in operational interruptions and repair costs, ensuring an efficient and economical operation.

Efficiency and Power-to-Size Ratio: Packing a Punch

Efficiency and a favorable power-to-size ratio are where squirrel cage motors truly shine. Thanks to their design, they can convert a high percentage of electrical power into mechanical power with minimal energy loss. Moreover, they achieve this efficiency in a compact size relative to the power they deliver, making them ideal for applications where space is at a premium.

Take electric vehicles (EVs) as a case in point. The propulsion systems of EVs benefit greatly from the high efficiency and powerful yet compact nature of these motors, contributing to longer battery life and more mileage per charge, pushing the boundaries of modern transportation.

Versatility Across the Spectrum: From Homes to Factories

Perhaps one of the most compelling advantages of squirrel cage electric motors is their broad range of applications. Their versatility allows them to be tailored to a vast array of power needs, from small motors in household appliances like blenders and fans to powerful versions driving industrial pumps and generators.

This widespread applicability can be seen in the example of automated production lines. Here, multiple squirrel cage motors operate in unison, driving various components of the production process with precision and reliability, demonstrating their adaptability and crucial role in modern manufacturing techniques.

The Workhorse of the Modern World

In wrapping up, the advantages of squirrel cage electric motors – reliability, cost-effectiveness, efficiency, and versatility – solidify their status as the workhorses of the modern world. Their integration into virtually every aspect of daily life, often unnoticed, is a testament to their indispensable role. Recognizing these benefits not only allows us to appreciate the genius behind their design but also encourages innovation in how we harness and optimize these motors for future applications, pushing the envelope of what’s possible across industries and our daily lives.

Common Concerns and Troubleshooting Squirrel Cage Electric Motors

Despite the numerous advantages of squirrel cage electric motors, like any piece of machinery, they aren’t immune to issues and faults. From overheating problems to bearing failures and rotor damage, these motors can require troubleshooting and preventative maintenance. This section aims to demystify these concerns and provide actionable advice, helping non-specialists understand and handle these issues, thereby extending the life and enhancing the performance of these motors.

Staying Cool: Overheating Issues and Solutions

Overheating can often plague squirrel cage electric motors. Causes can range from overload, improper ventilation, voltage fluctuations, to poor maintenance. Prolonged overheating can compromise motor efficiency and even cause irreversible damage.

Appropriate maintenance and problem detection are key to mitigating overheating. Ensure the motor has proper ventilation and isn’t operating beyond its capacity. Using an infrared thermometer, one can routinely monitor the motor’s temperature during operation, allowing for early detection of potential overheating.

Bearing the Load: Common Faults

Faults can manifest in squirrel cage motors due to various factors, such as bearing failures and rotor damage.

Bearing failures are often due to a lack of lubrication, excessive load, or dirt ingress. Listening for abnormal noises, like squealing or grinding, can help identify early bearing issues. Regular cleaning, proper handling, and appropriate lubrication can prevent such faults.

Rotor damage, though less common, can result from severe shock loads or electrical faults. Such issues generally require professional intervention but can be minimized through correct installation, balanced loads, and maintaining proper electrical conditions.

Tips and Tricks: Troubleshooting for Non-specialists

For non-specialists, troubleshooting squirrel cage motors might seem daunting. However, a few basic tips can aid the process:

- Visual Inspection: Often, a simple visual inspection can reveal issues like physical damage to wires, signs of overheating, or dust accumulation.

- Noise and Vibration: Unhealthy motors may produce abnormal noises or vibrations. Listening and feeling for such anomalies can aid early detection.

- Thermal Inspection: As mentioned earlier, monitoring operating temperature with an infrared thermometer can spotlight overheating issues.

Remember, while these tips provide preliminary solutions, certain issues will require professional intervention.

Maintaining Health: Preventative Maintenance Strategies

Preventative maintenance is essential in extending the life and maintaining the efficiency of squirrel cage motors. Key strategies include:

- Regular Cleaning: Keeping the motor dust-free prevents overheating and improves efficiency.

- Lubrication: Regularly lubricate bearings to reduce premature failure.

- Regular Inspections: Schedule routine visual and thermal inspections to detect potential issues early.

Keeping Motors Running Smoothly

While squirrel cage motors are generally reliable, they aren’t invincible. Overheating, bearing failures, rotor damage are common issues that can affect performance and longevity if not addressed promptly. Regular maintenance, combined with a keen eye (or ear) for abnormalities, can mitigate most problems. By troubleshooting effectively, we not only ensure the motor’s health but safeguard the myriad of systems and processes it powers, ultimately contributing to efficient and uninterrupted operations.

Future Trends and Innovations in Squirrel Cage Electric Motor Technology

The journey of squirrel cage electric motors, which form the backbone of myriad industrial and household applications, is on the cusp of exhilarating advancements. In an era defined by rapid technological progress and environmental consciousness, these motors are evolving. Innovations in materials, efficiency improvements, and the integration of smart technologies are set to redefine their operation, performance, and environmental impact. Let’s explore these budding trends and their implications for the future.

Revolutionizing Performance: Advances in Materials

At the heart of the latest innovations in squirrel cage electric motor technology are advances in materials. Developments in superconducting wires and lightweight alloys promise to launch motor efficiency and performance into new realms.

Superconducting Wires: Imagine motors almost free of electrical resistance. Superconducting materials, operating at extremely low temperatures, offer this possibility. When integrated into motors, they reduce energy losses significantly, heralding a new era of super-efficient motors. Though challenges in terms of cooling requirements and cost persist, ongoing research is making strides toward making superconducting motors a practical reality.

Lightweight Alloys: The adoption of lightweight alloys in motor construction enhances performance by reducing inertia and improving thermal management. These materials make motors not only more efficient but also easier to handle and install, offering benefits across their lifecycle.

Towards a Greener Future: Improvements in Efficiency and Environmental Impact

In the wake of global efforts to reduce carbon footprints, squirrel cage motors are undergoing transformations to emerge as beacons of efficiency and environmental stewardship.

Efficiency enhancements come from not just materials but also from design optimizations that reduce waste and improve energy conversion rates. Such innovations minimize the energy consumption and, by extension, the operational costs of these motors, providing a compelling case for their wider adoption in sectors from renewables to transport.

In parallel, attention to the environmental impact of manufacturing and disposal processes is increasing. The development of more recyclable materials and eco-friendly manufacturing practices points towards a sustainable approach to motor production.

Smart Motors and IoT: Ushering in Predictive Maintenance

The integration of smart technologies and the Internet of Things (IoT) with squirrel cage motors is set to revolutionize maintenance strategies and operational reliability.

Smart Motors: Embedded with sensors, smart motors provide real-time data on performance parameters like temperature, vibration, and efficiency. This wealth of information can be analyzed to optimize operation, detect anomalies, and even predict failures before they occur, transitioning maintenance from a routine schedule to a need-based strategy.

IoT Integration: By connecting motors to the IoT network, data collection and analysis become seamless and can be managed remotely. This not only simplifies maintenance but also enables a more responsive and interconnected infrastructure. Imagine motors that can self-diagnose issues and communicate with other devices to optimize their operation, reduce energy consumption, and prevent downtimes.

Case Study: The Smart Factory

Consider a smart factory setting, where multiple squirrel cage motors power conveyor belts, assembly lines, and ventilation systems. Through IoT integration, these motors constantly report their status to a central system that analyzes the data in real time. Before a bearing shows signs of failure, the system schedules maintenance, orders replacement parts, or adjusts the operation parameters to prevent damage. This level of automation and predictive maintenance exemplifies the transformative potential of smart motor technologies in industrial contexts.

The future of squirrel cage electric motor technology is vibrant, shaped by groundbreaking materials, a steadfast commitment to efficiency and sustainability, and the transformative powers of smart technologies. These innovations not only promise to enhance the performance and versatility of these motors but also their role in fostering a sustainable, technologically advanced future. As we stand on the brink of this exciting era, the potential applications and benefits of these advancements extend far beyond current horizons, offering a glimpse into a future powered by more efficient, reliable, and intelligent motor technology.

Choosing the Right Squirrel Cage Electric Motor for Your Application

Selecting the optimal squirrel cage electric motor for a particular application is a critical decision that can significantly influence the efficiency, performance, and lifespan of your equipment. Whether for industrial machinery, HVAC systems, or consumer appliances, the right motor not only ensures seamless operation but also optimizes energy consumption and reduces operational costs. In this context, understanding the key factors to consider, industry-specific recommendations, and how to interpret specifications and ratings are essential steps in making an informed decision.

Key Factors to Consider

When selecting a squirrel cage electric motor, several critical factors must be evaluated to ensure compatibility and performance:

- Power: The motor’s power rating indicates its capacity to perform work over time. Choosing a motor with the appropriate power output for your application is crucial to prevent underperformance or excessive energy consumption.

- Speed: Motor speed, measured in revolutions per minute (RPM), affects the operation of the driven equipment. Consider whether a fixed-speed motor suits your application or if a variable-speed motor would offer better control and efficiency.

- Torque: Torque, the force that causes rotation, is vital for starting and maintaining the operation of your machinery. Understand the torque requirements of your application, especially during startup, to select a motor that can handle the load.

- Size: The physical dimensions and mounting options of the motor must fit within your application’s space constraints and align with the installation environment.

Industry-specific Recommendations

Different industries have unique requirements that influence motor selection:

- Manufacturing: In manufacturing environments, motors often need to withstand heavy loads, high usage cycles, and harsh conditions. Robust motors with high starting torque and overload capacity are recommended.

- HVAC: For HVAC systems, energy efficiency and variable speed capabilities are paramount to adapt to fluctuating demands and optimize energy consumption.

- Consumer Appliances: Motors for appliances typically require compact size, quiet operation, and moderate power, with an emphasis on efficiency for reduced energy usage.

Understanding Specifications and Ratings

Navigating the specifications and ratings of squirrel cage electric motors is fundamental to choosing the right motor:

- Efficiency Rating: Indicates how effectively the motor converts electrical energy into mechanical energy. Higher efficiency ratings translate to lower operating costs.

- IP Rating: The Ingress Protection rating specifies the motor’s level of protection against solid objects and liquids, crucial for applications in challenging environments.

- Service Factor: A higher service factor means the motor can handle temporary overload conditions without damage, providing an additional margin of safety.

Real-World Example: Conveyor Belt System

Consider an industrial setting where a conveyor belt system transports heavy materials across a manufacturing plant. The right motor must offer sufficient power to move the weight of the materials, provide enough torque to start the belt with a full load, and operate at a speed that matches the production line’s requirements. It should also be robust enough to handle continuous operation and potential exposure to dust and debris. In this scenario, specifying a motor with adequate power and torque, an appropriate speed rating, a high service factor, and a suitable IP rating would be critical for optimal performance and reliability.

Overcoming Common Misconceptions

One common misconception is that bigger always means better. However, selecting a motor with specifications far beyond the actual requirements can lead to inefficiencies and increased costs. Another is underestimating the importance of the service factor and IP rating, which are crucial for long-term durability and operation in specific conditions.

Making an Informed Choice

Choosing the right squirrel cage electric motor is a nuanced decision that impacts the efficiency, operational cost, and reliability of your application. By carefully considering power, speed, torque, and size; adhering to industry-specific recommendations; and understanding the critical specifications and ratings, you can select a motor that perfectly matches your requirements. Keeping in mind real-world application scenarios and avoiding common misconceptions further ensures a well-informed choice that contributes to optimal performance and longevity of your equipment.

FAQs About Squirrel Cage Electric Motors

Q: What factors are crucial to consider for selecting a squirrel cage motor?

A: When choosing a squirrel cage motor, consider factors like required power output, speed, torque, and physical size. Efficiency rating, IP rating, and service factor are also vital considerations. Industry-specific requirements should guide your selection.

Q: Is it necessary to engage a professional for installing a squirrel cage motor?

A: While minor installations involving small motors might be feasible for skilled DIY enthusiasts, professional installation is highly recommended for most cases, particularly with larger, more complex systems. Professionals can ensure the proper alignment, wiring, grounding, and safety precautions adhered to, optimizing the lifespan and performance of your motor.

Q: How often should I perform maintenance on my squirrel cage motor?

A: The frequency of maintenance depends on several factors, including the intensity of use, environmental conditions, and the motor’s specifications. Regular visual inspections, vibration analysis, temperature monitoring, and periodic lubrication are good maintenance practices. Additionally, leveraging smart monitoring systems can help implement predictive maintenance, addressing issues before they lead to failures.

Q: How can squirrel cage motors contribute towards reducing environmental impact?

A: Energy-efficient motors play a significant role in reducing power consumption and CO2 emissions. Further, selecting motors with higher efficiency ratings and adhering to sound maintenance practices can prolong motor lifespans, reducing the need for replacements and minimizing waste. Industry trends towards use of recyclable materials and eco-friendly manufacturing practices also contribute to reducing the environmental impact.