This comprehensive article delves into the world of the squirrel cage induction motor, an unsung workhorse in a spectrum of industries. Starting with a detailed understanding of its principles and unique design features, the writeup explores its advantages, limitations, and practical applications. Case studies illustrate its versatility and operational value, while sections on troubleshooting and maintenance provide actionable insights. The discussion extends to the motor’s future trajectory, propelled by continuous innovation and emerging technologies. Readers will also find a thoughtful reflection on the enduring relevance of the squirrel cage induction motor in modern applications.

Introduction: The Underlying Principles of Squirrel Cage Induction Motor

The landscape of electromechanical engineering experienced a significant upheaval with the advent of induction motors, a class of workhorses that soon became indispensable in countless applications. Among these, the squirrel cage induction motor emerged as a pivotal innovation, revolutionizing efficiency and reliability in power conversion. Derived from the curious, cage-like structure of its rotor – reminiscent of a squirrel’s exercise wheel – this motor type has staked its claim as a cornerstone in modern industry.

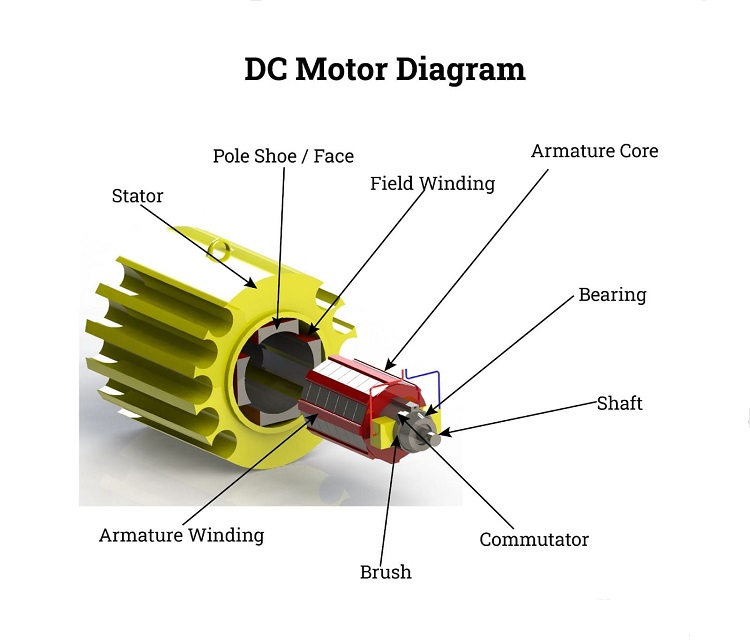

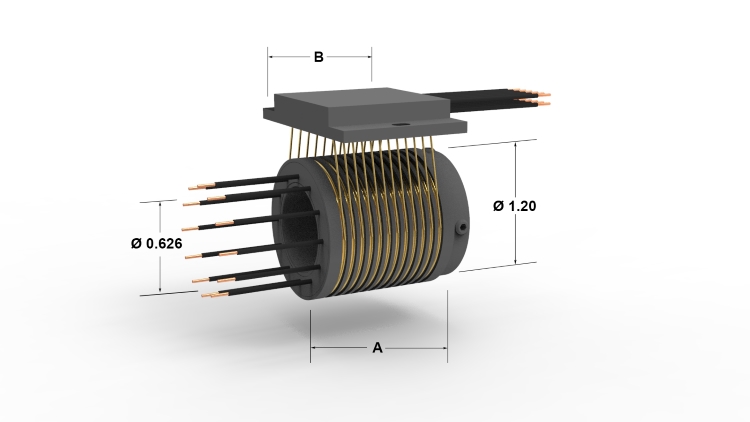

Its operation rests on the simple yet profound principle of electromagnetic induction, where a rotating magnetic field, generated by the stator, induces current within the rotor, thus setting it in motion. What sets the squirrel cage motor apart is not just its maintenance-free design, devoid of brushes and slip rings, but also its robustness and remarkable longevity. These characteristics are not merely theoretical virtues but are regularly exhibited in applications ranging from the air you breathe in offices, courtesy of HVAC systems, to the bottling plant that packages your beverages with machine-line precision. Addressing common queries, like concerns over energy consumption, our forthcoming segments will unravel the efficiency aspects that make squirrel cage motors a favored choice amidst a landscape where green technology holds sway.

Diligently designed, these motors harmonize the dance between alternating current and mechanical work, showcasing an elegant simplicity that belies the complexity of their application, setting the stage for a journey through the corridors of a technology that has quietly shaped the modern world.

Anatomy of a Squirrel Cage Induction Motor

The charm of the squirrel cage induction motor lies within its elemental design, a symphony of components operating seamlessly to translate electrical energy into mechanical work. Each component plays a crucial role in facilitating this dance.

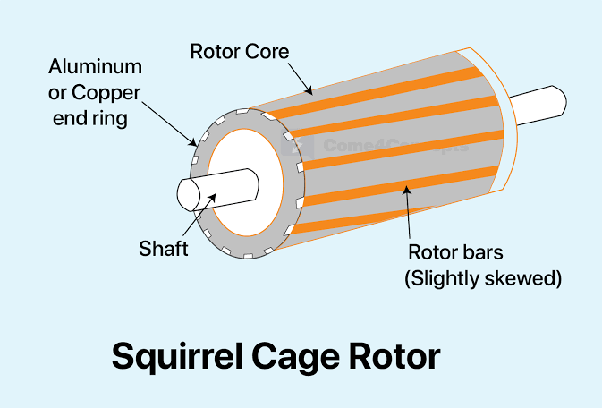

At the heart of this motor is the ‘squirrel cage’ rotor. It constitutes aluminum or copper conductors, shorted at each end by conducting bars – much like the rungs on a squirrel’s wheel – lending the structure both its functionality and its curious moniker. The stator, responsible for creating a rotating magnetic field, wraps itself around the rotor, its windings carefully arranged to facilitate optimal electromagnetic interactions.

The air gap, a region of non-magnetic insulating material between the stator and rotor, also plays a critical role. It’s not just an arbitrary space, but a finely-tuned component, ensuring optimal magnetic coupling while allowing for mechanical movement.

The motor casing not only offers structural support but also aids in thermal management by conducting heat away from critical components. In essence, every part, big or small, has a unique role to play, a purpose that justifies its existence in the ‘ecosystem’ of an induction motor.

Consider, for instance, an elevator system, a real-world application that is relatable to us all. The motor, hidden from our sight, powers the elevator while keeping the operation surprisingly silent and smooth. The careful design and placement of each component in our motor ensure that we rise or descend every floor without any disturbance, serving as a silent testament to the synergy in its design.

This chapter aims to peel back the layers of these vital components, revealing an organized complexity that underscores the technology’s efficacy and robustness while debunking misconceptions about its apparent simplicity.

The Benefits and Drawbacks of the Squirrel Cage Induction Motor

No invention exists without its unique set of advantages and inherent limitations; the squirrel cage induction motor is no exception. Understanding this duality provides a holistic view of its place in the fabric of electromechanical systems.

Renowned for its simplicity, the squirrel cage induction motor boasts a design characterized by minimal moving parts. This simplicity fosters its ruggedness, rendering it largely immune to mechanical wear and tear. Its longevity is well illustrated in industries such as mining, where motors work in harsh conditions yet exhibit a surprising durability. Additionally, their lower cost compared to their counterparts like synchronous or DC motors makes them an economical choice for countless businesses.

However, despite this roster of advantages, it would be remiss not to acknowledge the challenges. The squirrel cage motor, noted for its fixed speed operation, offers limited control in applications requiring variable speed. Another commonly cited limitation lies in its low starting torque, which may inhibit its usage in applications that demand high torque at start, like heavy-duty cranes.

Understanding the motor’s strength and weaknesses not only anticipates its behavior and performance in various situations, but also informs and guides appropriate motor selection. For instance, if you run a small conveyor belt in a production line, the energy efficiency achieved by using a squirrel cage motor might offset the higher initial cost of other types of motors.

The crucial point here is to match the right motor type to the requirements of the system, a principle that is as much a reflection of good engineering practice as it is a lesson in resource optimization. Acknowledging these limitations not only emphasizes a need for further innovation but also dispenses practical wisdom for industry professionals and hobbyists alike navigating the wide motor landscape.

Practical Applications of Squirrel Cage Induction Motor

Among the symphony of unseen orchestrators of our modern life, the squirrel cage induction motor occupies a pivotal role. Despite its unsung hero status, the breadth of its applications is astonishingly diverse, carving niches within households and industries alike.

Take HVAC systems, encountered virtually everywhere – from homes to offices, and malls to hospitals. These systems rely extensively on these motors for driving the compressor, fan, and blower units, ensuring a comfortable microclimate regardless of the caprices of the weather.

Stepping into the industrial realm unveils a panorama of machinery, from conveyor belts churning out chocolates faster than you could possibly eat, to drill presses shaping a metal sheet with precision unmatched by human hands. Behind these marvels, you’ll often find a squirrel cage motor lending its dependable service.

But why is it the motor of choice in these diverse applications? The answer lies in its blend of simplicity, durability, and cost-effectiveness. Consider an HVAC system as an example. Its inevitable exposure to a wide range of temperatures and weather conditions demands components that can withstand such variability, which is where these motors shine. In industries, where downtime equals revenue loss, their durability and low maintenance promise of minimum interruption make them an irresistible choice.

Practical applications yield significant insights, revealing the ‘why’ behind its ubiquity, debunking commonly held misconceptions, and potentially offering inspiration for innovative applications. This fusion of theory and practice instils an appreciation of the squirrel cage induction motor’s importance – a bit of mechanical poetry humming behind the panels of our modern life.

Case Studies Showcasing the Squirrel Cage Induction Motor in Action

The real-world efficacy and versatility of the squirrel cage induction motor are best illustrated through case studies, portraying how these motors solve complex problems across various industries. These examples highlight not only their technical prowess but also underscore their invaluable contribution to efficiency and innovation.

Elevating Agricultural Productivity

In the expansive fields of agriculture, the efficiency of irrigation systems is paramount. A case study from California, the United States, where water is as precious as gold, reveals the role of squirrel cage motors in redefining irrigation. By powering high-capacity pumps that deliver precise quantities of water to vast stretches of farmland, these motors have substantially reduced water wastage. The flawless operation, coupled with low maintenance requirements, has made them an indispensable asset in ensuring food security.

Revolutionizing the Public Water Supply

A city in Japan faced a significant challenge in ensuring a stable water supply to its growing population. The introduction of squirrel cage induction motors to drive the city’s water treatment and pumping stations marked a turning point. Their reliability meant that maintenance shutdowns were fewer and farther between, ensuring a consistent water supply. This case not only demonstrates the motor’s value in critical infrastructure but also its silent contribution to public health and welfare.

Innovating Manufacturing Efficiency

The automotive industry, known for its rigorous production demands, continuously seeks improvements in efficiency and reliability. A landmark instance occurred in a German automobile assembly plant, incorporating squirrel cage motors into their production lines. These motors, driving conveyor belts and robotic arms, heightened production speeds while reducing breakdowns, showcasing a stellar example of upgraded manufacturing processes.

Through these case studies, the squirrel cage induction motor emerges as more than just a component; it’s a catalyst for technological advancement, environmental conservation, and economic efficiency. By addressing common questions and showcasing their adaptability, the intention is to illuminate the integral role these motors play in not just powering machines but in also driving human progress.

Troubleshooting and Maintenance of Squirrel Cage Induction Motors

Even the most reliable systems require troubleshooting and maintenance from time to time. The squirrel cage induction motor is no exception, and through understanding its common issues and maintenance, we can ensure its longevity and efficiency.

Navigating Common Issues

Overheating

One of the most frequent afflictions for motors is overheating. This could stem from a variety of issues, including overloading, voltage imbalances, or inadequate cooling. A telltale case is when a Midwest manufacturing plant found their motors running hot; the culprit was clogged cooling fans choked with debris. Simple cleaning procedures rectified the problem.

Bearing Failures

Bearings are the linchpin allowing the rotor to turn smoothly. A classic example is found in textile mills, where fibrous material and dust often lead to bearing contamination. Regular inspection and cleanups, coupled with timely replacements, have proven to be the key to uninterrupted operation.

Electrical Failures

Electrical failures such as short circuits or insulation breakdown can lead to motor malfunctions. In one scenario, a motor failed in a commercial facility – investigation revealed insulation damage caused by moisture. Here, the solution was better environmental control and protective coating applications.

Emphasizing Preventive Maintenance

Cleanliness is Next to Godliness

A primary recommendation for preventive maintenance is cleanliness. Keeping motors clean from debris and contaminants can prevent a multitude of ills, particularly overheating and bearing failures.

Regular Inspections

Scheduled inspections are crucial. They can uncover potential problems such as unusual noises, which can indicate bearing deterioration, or spending heat which can signal an electrical issue.

Thermal Imaging

The use of modern techniques like thermal imaging can non-invasively pinpoint areas of excessive heat, often highlighting issues before they lead to a failure.

Vibration Analysis

For more comprehensive maintenance, implementing vibration analysis can catch mechanical imbalances or misalignments early, thereby preventing further damage.

Scheduled Downtime

Lastly, a case study from a large paper production company demonstrates the success of scheduled downtimes. By planning periodic stops, they were able to carry out thorough maintenance checks, which in turn improved their overall operational uptime.

The discourse on troubleshooting and maintenance crystallizes a truth: proactive care is the key to sustained motor performance. By addressing these elements with the diligence they deserve, the industry can continue to rely on the dependable nature of squirrel cage induction motors. Through this lens, maintenance isn’t just about preventing failure; it’s about ensuring operational excellence.

Future Trends and Technological Developments for the Squirrel Cage Induction Motor

As we stand on the promising precipice of a technologically augmented future, the squirrel cage induction motor is poised for an exciting evolution filled with innovation, adaptation, and transformation. Steering this course of change are two major factors: a relentless pursuit of energy efficiency and the integration of smart features.

Striding towards Energy Efficiency

The demand for energy-efficient systems has never been more urgent. This forms an impulsive force propelling motor technology toward innovations aimed at reducing energy consumption. One such promising development in squirrel cage induction motors is the concept of ‘load-sensing control’. By designing motors to adjust torque delivery based on the load, significant energy savings can be achieved – a revolutionary update to the widely deployed fixed torque models currently in use.

Embracing the Era of Smart Motors

In parallel, embracing the digital age’s possibilities has prompted a shift towards ‘smart’ motors. These motor systems, embedded with sensors and backed by powerful analytics, can self-monitor performance parameters, actively detect anomalies, and even predict failures before they occur – a concept known as ‘predictive maintenance’. Such advancements don’t just increase efficiency and reduce maintenance; they are transforming motors into intelligent contributors within industrial Internet of Things (IIoT) ecosystems.

Infilling Emerging Technologies

Path-breaking technologies such as Artificial Intelligence (AI) and Machine Learning (ML) are beginning to permeate motor systems. These tools process the sea of data provided by smart sensors, unlocking immense possibilities for performance optimization, fault prediction, and automation.

The Outlook Ahead

Looking ahead, these developments paint an optimistic picture of the squirrel cage induction motor’s future. They will continue to silently propel humanity forward, albeit in newer, more efficient, and smarter forms. Companies like ABB and Siemens, known for their pioneering work, are already investing heavily in the research and development of these advanced motor systems.

Indeed, these developments don’t just herald a transformative era for the motors themselves, but they also enrich the landscape of opportunities for industries utilizing them. With motor systems turning smarter, more efficient, and more predictive, they are set to catalyze a new wave of industrial revolution that blurs the lines between the mechanical and digital realms. The squirrel cage induction motor, which has been a steadfast workhorse for over a century, seems ready to gallop forward, navigating the labyrinth of technological breakthroughs to secure an even more central role in our future.

Conclusion: The Persistent Relevance of the Squirrel Cage Induction Motor

As we journey through the exploration of the squirrel cage induction motor, it’s undeniable the profound impact it has had across multiple facets of modern industry and technology. This concluding section encapsulates the significance and ongoing relevance of this engineering marvel.

Synthesis of Core Insights

The squirrel cage induction motor, with its humbling beginnings, has showcased unparalleled durability, efficiency, and adaptability. Characterized by its straightforward design, low maintenance requirements, and reliable operation, it stands as a testament to innovation in electric motor development. From powering agricultural machinery, and advancing manufacturing lines, to propelling water and sewage systems, its applications are boundless. Furthermore, the motor’s evolution, driven by advancements in materials science, control systems, and computational capabilities, underscores its adaptability in a rapidly changing technological landscape.

The Indelible Mark on Modern Applications

Reflecting on the importance of the squirrel cage induction motor illuminates its foundational role in the tapestry of modern civilization. Its capacity to transition seamlessly into the digital age via integration with IoT and AI systems reaffirms its enduring relevance. The motor’s evolution reflects not just an adaptation to new technological paradigms but a redefinition of what’s possible inefficiency and smart automation.

For instance, consider the transformative impact of energy-efficient motors in combating climate change by reducing industrial power consumption. Similarly, smart motor innovations are at the forefront of predictive maintenance, which mends the bridge between operational continuity and cost efficiency. These advancements not only highlight the motor’s significance but also its contribution to sustainable and intelligent industry practices.

Looking Forward

In an era defined by rapid technological progress and environmental consciousness, the squirrel cage induction motor continues to evolve, embracing new technologies while enhancing its core attributes of reliability and efficiency. Its journey from a simple yet effective design to becoming the linchpin in complex, intelligent systems is a narrative of human ingenuity and the quest for better, more sustainable technological solutions.

As we stand at the threshold of future breakthroughs, it’s clear that the squirrel cage induction motor will continue to be a key player in the advancement of numerous applications. Its ongoing transformation and application in diverse fields underscore its versatility and enduring relevance, reinforcing the motor’s position not just as a component but as a cornerstone of modern engineering.

In summing up the journey of the squirrel cage induction motor, it is a reminder of the power of innovation to transcend time, offering solutions today and promising potential for tomorrow. Its story is far from complete; rather, it is poised for the next chapter, promising new developments and applications that will continue to shape our world.