Slip rings are critical components enabling the transmission of power and data between stationary and rotating parts. In the pursuit of high-speed and seamless data communication, gigabit ethernet slip rings have become an essential tool in several tech-heavy industries.

Introduction Gigabit Ethernet Slip Rings

Gigabit Ethernet slip rings are a breakthrough technology designed to accommodate the increasing demand for rapid and high-volume data transmission. These innovative devices function as an interface between stationary and rotating components in a system, allowing incessant transmission of power and gigabit ethernet data simultaneously. Leveraging the power of ethernet connectivity, these slip rings function at the speed of 1 gigabit per second, offering an efficient solution for systems involving rotational movements.

The relevance and importance of gigabit ethernet slip rings are particularly heightened in today’s technologically advanced world. We live in an era where technology permeates virtually every sphere of human activity and where speedy, reliable, and uninterrupted data transmission is critical. From satellite communication and wind energy conversion systems to cutting-edge industrial automation processes, gigabit ethernet slip rings come into play to ensure the seamless functioning of different systems.

As our world becomes increasingly connected and as high-speed data communication becomes more critical, the role of gigabit ethernet slip rings only becomes more vital. With their unique capability to support high-speed data transmission between rotating and stationary components, gigabit ethernet slip rings are not just a mere component – they are the enablers of our advanced digital present and future.

Key challenges of slip rings in Gigabit Ethernet: The physical contact structure of the slip ring (metal ring and brush) causes signal attenuation, noise interference and bandwidth limitation. Gigabit Ethernet requires 125MHz frequency and 1.4ns low jitter, but traditional slip rings are prone to packet loss due to contact resistance fluctuations (5mΩ to 50mΩ) and parasitic capacitance (1-5pF) during dynamic rotation. For example, industrial robots have a 50% drop in throughput due to slip ring signal reflection, which requires high-frequency optimization design to solve.

Understanding the Functionality of Gigabit Ethernet Slip Rings

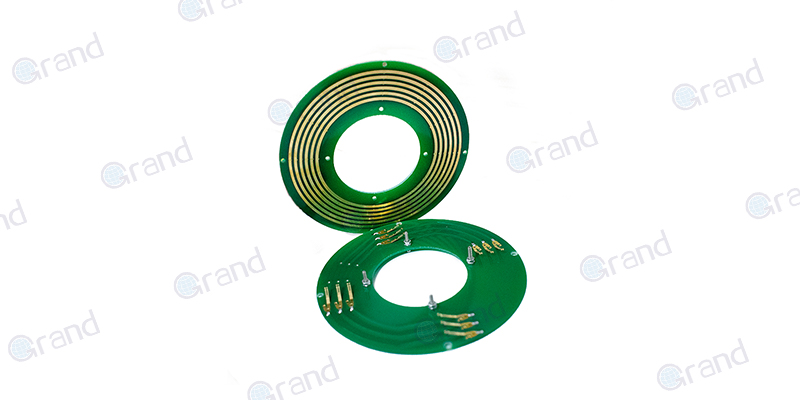

Gigabit Ethernet slip rings are specially engineered devices that facilitate seamless data transmission between a stationary structure and a rotating component. Their operation revolves around a unique principle – simultaneously ensuring rotary motion and transmitting data and power.

The core mechanism of a gigabit ethernet slip ring involves an electromechanical device known as the ‘rotor,’ which rotates in sync with the rotating component of the assembly. The ‘stator’ remains stationary, interfaced with the non-moving part of the assembly. Conductive rings are attached to the rotor, while brush assemblies align with the stator. As electricity flows through these conductive rings, the brushes – sliding over the rotating rings while maintaining constant contact – pick up the electrical signals and transfer them to the stationary circuit, through ethernet protocols at speeds up to 1 Gbps. The central idea lies in maintaining this data transmission seamlessly, despite the rotational motion.

The advantages of using slip rings for Ethernet data transmission are manifold. First and foremost, they significantly enhance the speed and reliability of data communication between the rotating and stationary parts of a machine. The network speed can reach up to 1 Gbps, thereby facilitating the handling of high volumes of data with minimal latency.

Moreover, these slip rings can transmit power and data simultaneously, which is a major advantage in multifunctional systems. This dual functionality not only conserves space and reduces installation complexity but lowers overall system maintenance and propensity for errors.

The utility and efficiency of gigabit ethernet slip rings shine across a wide range of high-tech applications, offering unparalleled support for state-of-the-art industrial machinery, wind turbines, communication devices, and more. Their continued usage and development mirror the ever-evolving need for exceptional data transmission solutions in our technologically interconnected world.

Gigabit Ethernet Slip Rings Technical Specifications

Gigabit Ethernet slip rings are specialized electromechanical devices designed to allow the transmission of Ethernet signals across rotating interfaces. They are commonly used in applications where high-speed data communication is required between stationary and rotating parts, such as in industrial machinery, medical devices, robotics, and wind turbines. Below is a detailed description of the technical specifications and features of Gigabit Ethernet slip rings:

Technical Specifications

- Data Transmission Rate:

- Gigabit Ethernet slip rings support data transmission rates of up to 1 Gbps (1000 Mbps), enabling the high-speed transfer of large amounts of data with minimal latency.

- Number of Channels:

- Typically, these slip rings come with multiple channels dedicated to Ethernet signals, ranging from 1 to 4 channels or more, allowing simultaneous transmission of multiple data streams.

- Connector Types:

- These slip rings are equipped with standard RJ45 connectors, which are compatible with most Ethernet cables and devices, ensuring ease of integration into existing networks.

- Electrical Specifications:

- Voltage Rating: The slip rings are designed to operate at voltages ranging from 12V to 24V DC, depending on the specific model.

- Current Rating: Current capacity may vary, often ranging from 1A to 10A per channel, depending on the design and intended application.

- Insertion Loss:

- Insertion loss is a critical parameter, typically kept below 1 dB to ensure minimal signal degradation during transmission. Lower insertion loss contributes to maintaining the integrity of high-speed Ethernet signals.

- Return Loss:

- Return loss is generally specified to be better than -20 dB, which indicates the efficiency of signal reflection minimization, thereby reducing interference and data errors.

- Operating Frequency:

- These slip rings are designed to handle the full frequency range required by Gigabit Ethernet, which operates at frequencies up to 125 MHz.

- Insulation Resistance:

- High insulation resistance, usually greater than 1000 MΩ at 500 VDC, ensures the slip ring’s electrical isolation between channels, reducing the risk of cross-talk and interference.

- Dielectric Strength:

- Dielectric strength typically exceeds 1000V AC at 50Hz for 60 seconds, providing robust protection against electrical breakdown in high-voltage environments.

Mechanical Specifications

- Size and Form Factor:

- Gigabit Ethernet slip rings come in various sizes, with outer diameters ranging from 22mm to 100mm or more, and lengths from 30mm to 200mm, to accommodate different installation spaces and application requirements.

- Rotational Speed:

- These slip rings can operate at rotational speeds ranging from 100 RPM to 5000 RPM, depending on the model. For applications requiring higher speeds, the 2000RPM high-speed Ethernet slip ring offers a balanced solution. Operating at 2000 RPM, it provides enhanced performance for Ethernet networks that demand higher data transmission speeds without compromising signal integrity. Higher-speed models are available for more specialized applications, ensuring flexibility in selecting the right slip ring for specific operational requirements.

- Materials:

- The housing is typically made from high-quality materials such as aluminum or stainless steel, offering durability and resistance to corrosion.

- The conductive components are often gold-plated to ensure low contact resistance and long service life.

- Operating Temperature Range:

- These slip rings are designed to function in a wide temperature range, typically from -40°C to +80°C, ensuring reliable performance in various environmental conditions.

- Protection Rating:

- Gigabit Ethernet slip rings are available with various protection ratings, such as IP65 or IP68, which indicate their resistance to dust, water, and other environmental factors.

Additional Features

- Hybrid Designs:

- Some Gigabit Ethernet slip rings are hybrid models that combine power channels, analog signal channels, and even optical channels, in addition to Ethernet, to support complex systems requiring multiple types of signal transmission.

- Customization:

- Many manufacturers offer customization options for Gigabit Ethernet slip rings, allowing for specific adaptations to meet unique application requirements, such as varying numbers of channels, different connector types, or specific material choices.

- Low Crosstalk:

- These slip rings are designed with minimal crosstalk between channels, ensuring high fidelity in data transmission, crucial for applications where signal integrity is paramount.

- Maintenance-Free Operation:

- High-quality Gigabit Ethernet slip rings are often designed for long-term, maintenance-free operation, with an emphasis on reliability and durability in demanding industrial environments.

- Vibration and Shock Resistance:

- Some models are specifically designed to withstand high levels of vibration and shock, making them suitable for use in harsh environments, such as in military or aerospace applications.

These technical specifications ensure that Gigabit Ethernet slip rings provide reliable, high-speed data transmission in rotating systems, making them essential components in modern industrial and technological applications.

Advantages and Applications of Gigabit Ethernet Slip Rings

Advantages of Gigabit Ethernet Slip Rings

- High-Speed Data Transmission:

- Gigabit Ethernet slip rings enable the transmission of data at speeds up to 1 Gbps, ensuring quick and efficient communication between stationary and rotating parts of a system. This high data rate is crucial for applications requiring real-time data exchange.

- Minimal Signal Loss and Interference:

- These slip rings are designed with low insertion and return losses, which minimize signal degradation and maintain data integrity. The low crosstalk design further reduces interference between channels, ensuring clear and reliable data transmission.

- Versatility:

- Gigabit Ethernet slip rings are available in various configurations, including hybrid models that combine Ethernet channels with power, analog signals, or optical channels. This versatility makes them suitable for a wide range of applications.

- Compact and Durable Design:

- These slip rings are typically compact, allowing for easy integration into systems with limited space. Their durable construction, often using high-quality materials like stainless steel and gold-plated contacts, ensures long-term reliability and resistance to environmental factors such as dust, moisture, and temperature extremes.

- Maintenance-Free Operation:

- Designed for long-term use, Gigabit Ethernet slip rings often require little to no maintenance, reducing operational downtime and associated costs. Their robust design supports continuous operation in demanding environments.

- Wide Range of Operating Conditions:

- Gigabit Ethernet slip rings are built to function in diverse environmental conditions, including extreme temperatures, high humidity, and exposure to dust or water, making them suitable for both indoor and outdoor applications.

- Customizability:

- Many manufacturers offer customization options, allowing users to specify the number of channels, connector types, and materials to meet the exact needs of their application. This customizability enhances the slip ring’s performance and suitability for specific tasks.

- Smooth Rotational Performance:

- These slip rings support smooth rotation at varying speeds, from low to high RPMs, without compromising data transmission quality. This is essential in applications where rotational motion is continuous or fluctuating.

Applications of Gigabit Ethernet Slip Rings

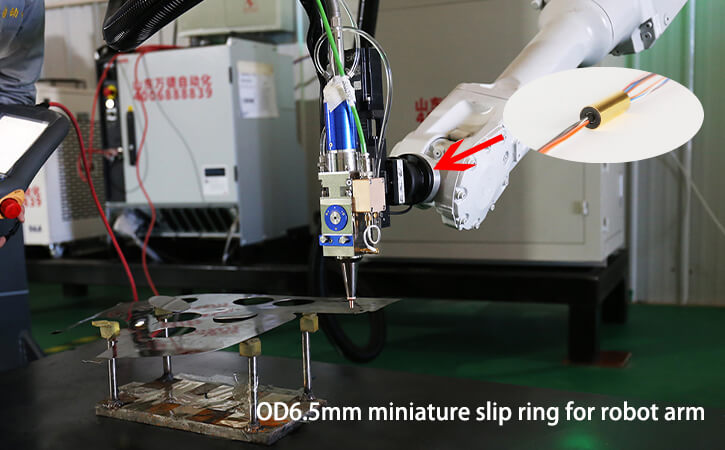

- Industrial Automation:

- In automated manufacturing systems, Gigabit Ethernet slip rings are used to transmit data between robotic arms, sensors, and controllers, enabling precise and real-time control of machinery.

- Surveillance Systems:

- These slip rings are commonly found in pan-tilt-zoom (PTZ) cameras used in surveillance systems, where they facilitate continuous rotation while maintaining high-speed data transmission for video feeds.

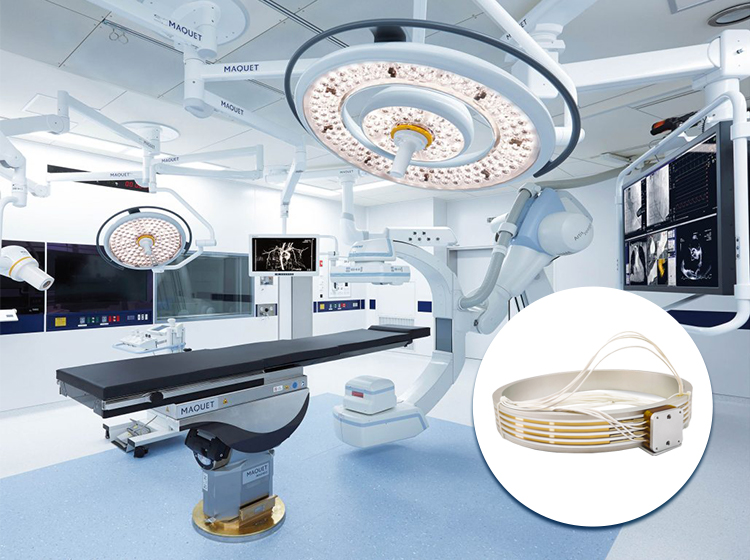

- Medical Imaging Equipment:

- In medical devices like CT scanners and MRI machines, Gigabit Ethernet slip rings enable the transmission of large volumes of data from rotating imaging components to stationary processing units, ensuring high-resolution images with minimal lag.

- Wind Turbines:

- Wind turbines use Gigabit Ethernet slip rings to transmit data from sensors on the rotating blades to the control systems in the stationary hub. This data is critical for monitoring performance and optimizing energy output.

- Rotating Radar Systems:

- In radar systems, especially those used in military or aerospace applications, these slip rings facilitate the continuous rotation of radar antennas while transmitting high-speed data to processing units, ensuring accurate and real-time tracking.

- Robotics:

- Gigabit Ethernet slip rings are essential in robotic systems, especially those that require 360-degree rotation, such as robotic arms and automated guided vehicles (AGVs). They ensure uninterrupted communication between sensors, controllers, and actuators.

- Marine and Offshore Equipment:

- In marine environments, these slip rings are used in equipment like underwater cameras and ROVs (Remotely Operated Vehicles) that require continuous data transmission while rotating, all while being exposed to harsh conditions.

- Aerospace and Defense:

- In aerospace applications, Gigabit Ethernet slip rings are employed in various systems, such as gimbals for missile tracking, where reliable, high-speed data transmission is crucial in high-stress environments.

- Broadcasting and Entertainment:

- These slip rings are used in broadcasting equipment like rotating cameras or satellite communication systems to transmit video and data signals without interruption during rotation.

Entertainment Equipments

- Automotive Testing Equipment:

- In automotive testing setups, Gigabit Ethernet slip rings are used to transmit data from rotating parts, such as wheels or drive shafts, to stationary data acquisition systems, aiding in performance analysis and testing.

The combination of high-speed data transmission, reliability, and versatility makes Gigabit Ethernet slip rings a critical component in a wide array of industries and applications.

Key Features of Gigabit Ethernet Slip Rings

Gigabit Ethernet slip rings come equipped with numerous technical features, signaling both their superior performance capabilities and alignment with industry-leading acceptance standards.

One of the critical features of these slip rings is the high IP (Ingress Protection) rating, indicating the level of protection against solid objects, including dust, and liquid ingress. This IP rating, often IP65 or higher, is emblematic of the devices’ robustness, ensuring reliable and undisturbed operation even in harsh environmental conditions.

Mean Time Between Failure (MTBF) is another notable metric for these slip rings. A high MTBF indicates the reliability and longevity of the slip ring in operational environments. Gigabit Ethernet slip rings generally have an MTBF of tens of thousands to hundreds of thousands of hours, further extending their operational life and reducing the need for frequent replacements or repairs.

Noise and loss levels are key parameters when considering data transmission components. For Gigabit Ethernet slip rings, noise levels are designed to be minimal, and the signal loss rates remain significantly low even under full rotational speed. These abilities ensure smooth and distortion-free transmission of data, contributing substantially to the system’s overall performance precision.

In addition to these, Gigabit Ethernet slip rings can operate under a wide range of conditions. They can endure varying temperature, altitude, and humidity levels. This adaptability makes them suitable for diverse applications, from indoor manufacturing environments to outdoor communication systems and remote location operation centers.

Moreover, these slip rings also conform to different ethernet standards like 10Base-T, 100Base-T, and 1000Base-T, reliably supporting diverse network transmission speeds.

In essence, the advanced technical features and conformity to critical acceptance standards of Gigabit Ethernet slip rings underline their unmatched performance, flexibility, and reliability, aptly meeting the data and power transmission needs of today’s high-tech applications. Their influence extends far beyond just being a mechanical device, reshaping the reliability and efficacy of various communication systems surrounding us.

Gigabit Ethernet Slip Rings: EH Series

The EH Series of Gigabit Ethernet Slip Rings are designed to meet the demands of high-speed data transmission in rotating systems, offering reliable performance and durability. Below is an overview of the EH Series, highlighting its key features, specifications, and typical applications.

Key Features of the EH Series

- High-Speed Data Transmission:

- The EH Series supports Gigabit Ethernet transmission rates of up to 1 Gbps, ensuring fast and reliable data communication across rotating interfaces.

- Multi-Channel Design:

- Available in various configurations, the EH Series can support multiple Ethernet channels (typically 1 to 4), allowing simultaneous data streams. This is particularly useful in complex systems that require multiple data inputs and outputs.

- Compact and Durable Construction:

- The EH Series slip rings are designed with a compact form factor, making them suitable for applications with limited installation space. The durable construction, often with a metal housing and gold-plated contacts, ensures long-term reliability and resistance to environmental stressors.

- Low Crosstalk and Signal Integrity:

- The EH Series is engineered to minimize crosstalk between channels, maintaining high signal integrity, which is critical for applications requiring precise and error-free data transmission.

- Wide Operating Temperature Range:

- The EH Series slip rings can operate in a broad temperature range, typically from -40°C to +80°C, making them suitable for both indoor and outdoor applications, including harsh environments.

- Hybrid Capability:

- Some models in the EH Series offer hybrid configurations, combining Gigabit Ethernet channels with power circuits, analog signals, or other communication types, providing a versatile solution for complex systems.

- Easy Integration:

- The slip rings in the EH Series come with standard RJ45 connectors, facilitating easy integration with existing network cables and devices. This plug-and-play capability reduces installation time and complexity.

- Maintenance-Free Operation:

- Designed for long service life, the EH Series requires minimal maintenance, ensuring continuous operation with reduced downtime.

Technical Specifications

- Data Transmission Rate:

- Up to 1 Gbps per channel.

- Number of Channels:

- Available with 1 to 4 Ethernet channels.

- Connector Type:

- Standard RJ45 connectors.

- Operating Voltage:

- 12V to 24V DC, depending on the model.

- Current Rating:

- Typically 1A to 10A per channel for power circuits in hybrid models.

- Insertion Loss:

- Less than 1 dB to ensure minimal signal degradation.

- Return Loss:

- Better than -20 dB to minimize signal reflection.

- Operating Frequency:

- Supports up to 125 MHz for Gigabit Ethernet.

- Insulation Resistance:

- Greater than 1000 MΩ at 500 VDC.

- Dielectric Strength:

- Over 1000V AC at 50Hz for 60 seconds.

- Rotational Speed

- Supports rotational speeds from 100 RPM to 5000 RPM, depending on the model.

- Protection Rating:

- IP65 or higher for certain models, ensuring resistance to dust and water.

Applications of the EH Series

- Industrial Automation:

- Used in robotic arms, automated machinery, and conveyor systems for high-speed data transmission in rotating components.

- Medical Equipment:

- Ideal for medical imaging systems, such as CT and MRI machines, where continuous rotation and high data transfer rates are necessary.

- Surveillance and Security Systems:

- Employed in PTZ cameras and other surveillance systems that require continuous rotation and stable data transmission.

- Wind Turbines:

- Transmits data from sensors on rotating blades to the stationary control system, essential for monitoring and optimizing turbine performance.

- Aerospace and Defense:

- Suitable for radar systems, missile tracking, and other aerospace applications requiring reliable high-speed data transmission under rotation.

- Broadcasting Equipment:

- Used in rotating cameras and satellite systems to ensure uninterrupted video and data transmission.

- Marine Applications:

- Deployed in underwater equipment and ROVs, where data needs to be transmitted reliably in harsh marine environments.

- Automotive Testing:

- Applied in testing setups where rotating parts like wheels or drive shafts need to transmit data to stationary monitoring equipment.

The EH Series of Gigabit Ethernet Slip Rings is a versatile and robust solution for any application requiring high-speed data transmission across a rotating interface. With its wide range of configurations, hybrid capabilities, and durable design, the EH Series offers reliable performance in even the most demanding environments.

Contactless 1Gb/s Ethernet Slip Rings

Contactless 1 Gb/s Ethernet slip rings, also known as contactless rotary joints or contactless rotary transmitters, are advanced devices that enable the transmission of high-speed Ethernet signals across rotating interfaces without the need for physical contact between the rotating and stationary parts. These devices utilize electromagnetic, optical, or capacitive coupling to achieve this transmission, offering several advantages over traditional slip rings.

Key Features and Advantages

- Contactless Data Transmission:

- The primary advantage of contactless Ethernet slip rings is the elimination of physical contact between the rotating and stationary components. This results in significantly reduced wear and tear, leading to a longer operational lifespan and minimal maintenance.

- High-Speed Data Transfer:

- Contactless slip rings are designed to support data transmission rates of up to 1 Gb/s (1000 Mbps), ensuring that they can handle high-speed Ethernet communication with minimal signal degradation.

- Reduced Signal Loss:

- These devices typically offer lower insertion loss and higher signal integrity compared to traditional contact-based slip rings. This results in more reliable data transmission, especially in applications requiring high fidelity.

- No Electrical Noise:

- Since there is no physical contact, contactless slip rings eliminate electrical noise and sparking, making them ideal for sensitive environments and applications where signal purity is critical.

- High Rotational Speed:

- Contactless slip rings can operate at very high rotational speeds, often exceeding those of traditional slip rings, without affecting data transmission quality. This makes them suitable for applications involving high-speed rotation.

- Wide Bandwidth:

- These devices can handle a wide range of frequencies, making them compatible with various Ethernet protocols and other high-frequency signals, offering flexibility in application.

- Compact and Lightweight:

- Contactless slip rings are generally more compact and lightweight compared to traditional models, which can be a crucial factor in applications with space or weight constraints.

- Low Maintenance:

- With no physical contacts to wear out, contactless slip rings require minimal maintenance, reducing downtime and operational costs.

- Vibration and Shock Resistance:

- Due to their non-contact nature, these slip rings are more resistant to vibration and mechanical shock, making them ideal for harsh and demanding environments.

- Environmental Resistance:

- Many contactless slip rings are designed to operate in extreme environmental conditions, including high temperatures, humidity, and exposure to dust or moisture, often featuring high IP ratings for protection.

Applications of Contactless 1 Gb/s Ethernet Slip Rings

- Rotary Radar Systems:

- Used in radar systems where continuous rotation is required, such as in military and aerospace applications, to transmit high-speed data without interference or signal degradation.

- High-Speed Medical Imaging:

- Ideal for use in medical imaging equipment like MRI and CT scanners, where they ensure reliable data transmission during continuous rotation without generating electrical noise that could affect image quality.

- Robotics and Automation:

- Employed in robotic arms and automated machinery that require continuous rotation and high-speed data communication, ensuring smooth operation and precision control.

- Wind Turbines:

- Used in the rotating components of wind turbines to transmit data from sensors to the control system, crucial for performance monitoring and optimization in renewable energy applications.

- Surveillance Systems:

- Integrated into PTZ cameras and other rotating surveillance equipment to enable continuous 360-degree rotation while maintaining high-speed data transmission for real-time video feeds.

- Aerospace and Defense:

- Utilized in advanced aerospace applications, such as gimbals for tracking systems or rotating communication systems, where reliable high-speed data transmission is essential under extreme conditions.

- Broadcasting Equipment:

- Used in broadcasting systems, such as rotating cameras or satellite communication devices, to ensure uninterrupted data transmission even during continuous rotation.

- Marine Applications:

- Employed in underwater vehicles and marine exploration equipment where continuous rotation and reliable data transmission are required under challenging conditions.

Selection Criteria for Contactless Ethernet Slip Rings

- Data Transmission Rate:

- Ensure the slip ring supports the required 1 Gb/s Ethernet transmission rate for your application.

- Rotational Speed:

- Consider the maximum rotational speed of your application and choose a slip ring that can operate efficiently at that speed.

- Environmental Conditions:

- Evaluate the environmental conditions (temperature, humidity, dust, etc.) where the slip ring will be used and select a model with an appropriate IP rating.

- Signal Integrity:

- Look for a contactless slip ring with low insertion loss and high return loss to maintain signal integrity.

- Size and Weight:

- Ensure the slip ring’s size and weight are compatible with your system’s design and constraints.

- Reliability and Maintenance:

- Opt for a slip ring known for high reliability and low maintenance requirements to minimize operational disruptions.

- Customization Options:

- If your application has unique requirements, consider slip rings that offer customization, such as specific connector types or hybrid configurations.

Contactless 1 Gb/s Ethernet slip rings offer significant advantages over traditional slip rings, particularly in applications that require high-speed data transmission, minimal maintenance, and operation under challenging conditions. By selecting a slip ring that meets the specific needs of your application, you can ensure reliable and efficient performance in a wide range of industries.

Selecting Gigabit Ethernet Slip Rings

Selecting the right Gigabit Ethernet slip ring for your application involves considering several key factors to ensure compatibility, reliability, and optimal performance. Here’s a guide to help you make an informed decision:

1. Determine the Data Transmission Requirements

- Speed: Ensure that the slip ring supports Gigabit Ethernet (1 Gbps). Verify that it meets the bandwidth requirements of your application, particularly if it involves high data volumes or real-time communication.

- Number of Channels: Determine how many Ethernet channels you need. Some applications may require multiple channels to transmit data streams simultaneously. Choose a slip ring that can support the required number of channels.

2. Consider the Mechanical and Environmental Constraints

- Size and Form Factor: Evaluate the available space for installation. Slip rings come in various sizes, so ensure the selected model fits within your system’s mechanical constraints.

- Rotational Speed: Consider the rotational speed of your application. Slip rings are rated for different RPMs. Ensure the slip ring can handle the maximum speed without compromising data transmission quality.

- Operating Environment: Assess the environmental conditions where the slip ring will be used:

- Temperature Range: Choose a slip ring that can operate within the temperature extremes of your environment.

- Protection Rating: If the slip ring will be exposed to dust, moisture, or harsh conditions, opt for a model with an appropriate IP rating (e.g., IP65 or IP68).

3. Electrical Specifications

- Voltage and Current Ratings: If the slip ring is a hybrid model that also transmits power, ensure it meets the voltage and current requirements of your application. Check that the power channels are isolated from the data channels to prevent interference.

- Signal Integrity: Look for slip rings with low insertion loss (less than 1 dB) and high return loss (better than -20 dB) to ensure minimal signal degradation and maintain high data integrity.

4. Connector Type and Compatibility

- Ethernet Connectors: Standard RJ45 connectors are commonly used for Ethernet connections. Ensure the slip ring is compatible with the Ethernet cables and devices you plan to use.

- Customization Options: If your application has specific connector requirements or needs a different configuration, consider slip rings that offer customization.

5. Hybrid Capabilities

- If your application requires more than just Ethernet data transmission (e.g., power, analog signals, optical signals), look for hybrid slip rings that combine these functionalities. This can simplify installation and reduce the number of components in your system.

6. Reliability and Maintenance

- Durability: Choose a slip ring made from high-quality materials, such as stainless steel or gold-plated contacts, to ensure long-term durability and resistance to wear and corrosion.

- Maintenance-Free Operation: Opt for a slip ring designed for maintenance-free operation, especially if your application requires continuous use with minimal downtime.

7. Application-Specific Requirements

- Industrial Automation: For robotic arms and automated machinery, prioritize slip rings with high rotational speed capability and robust construction to withstand industrial environments.

- Medical Equipment: In medical imaging systems, ensure the slip ring provides stable and high-fidelity data transmission with minimal signal loss.

- Surveillance Systems: For PTZ cameras, select a slip ring that offers smooth operation and stable data transfer for uninterrupted video feeds.

- Aerospace and Defense: If used in aerospace applications, the slip ring should be rugged, vibration-resistant, and capable of operating in extreme conditions.

8. Manufacturer Reputation and Support

- Quality Assurance: Choose a slip ring from a reputable manufacturer known for high-quality products and reliable performance.

- Technical Support: Ensure that the manufacturer offers strong technical support and customer service to assist with installation, troubleshooting, and customization if needed.

9. Budget Considerations

- While selecting a slip ring, balance your budget with the required specifications. Higher-end models may offer more features and greater reliability, but make sure these align with your actual needs to avoid unnecessary expenses.

10. Testing and Validation

- Prototyping: Before full-scale implementation, consider testing the slip ring in a prototype or pilot system to ensure it meets your performance expectations under real-world conditions.

- Certification: Check if the slip ring meets industry standards and certifications relevant to your application, such as ISO, RoHS, or CE, which can be crucial for compliance in certain industries.

By carefully evaluating these factors, you can select a Gigabit Ethernet slip ring that meets the technical, environmental, and operational requirements of your application, ensuring reliable and efficient performance.

Gigabit Ethernet Slip Rings Installation Process

Installing Gigabit Ethernet slip rings requires a certain level of technical competence, as it’s crucial to ensure that the installation process doesn’t interfere with the slip ring’s functionality or the overall system’s efficiency. Here is a stepwise process generalizing the installation procedure:

- Unpacking and Inspection: Carefully open the packaging and inspect the slip ring for any visible signs of damage or anomalies during transit or storage. Ensure that the slip ring matches the specifications you ordered.

- Check Components: Verify that you’ve received all the necessary components for installation, including adaptors or any other device-specific accessories according to the provided installation guide.

- Identify Installation Spot: Identify the exact position in your machinery where the slip ring will be installed. This step usually depends on the nature and design of your equipment.

- Mounting: Carefully fix the slip-ring onto its position, ensuring that the rotary and static parts are correctly aligned with the machine’s corresponding areas. For this step, it’s crucial to follow the manufacturer’s instructions closely.

- Connect Wires: Connect the rotator and stator wires to the appropriate parts of the assembly. Remember, correctly connecting the wires is vital for the efficient operation of the slip ring. Confirm wire connections against the circuit diagram provided by the manufacturer.

- Testing: Once fully installed, test the slip ring’s operation. This can usually involve checking for correct data transmission, power transmission, or any other sign of potential malfunction.

Common errors to avoid during installation include:

- Ignoring the manufacturer’s instructions: It’s essential to follow the installation guide accurately since it is tailored to the specific slip ring model.

- Incorrect wire connections: Misconnection of wires can seriously impact the operation of the slip ring and possibly even lead to failure. Always confirm wire connections with the circuit diagram provided by the manufacturer.

- Forcing the Slip Ring into Place: Using excessive force during the installation can cause damage to the slip ring or render it ineffective. The installation process should be carried out with precision and care.

It’s important to note that depending on the complexity of your machine and the specific model of the gigabit ethernet slip ring, the overall installation process may vary. Therefore, always refer to the provided instructions and, when in doubt, consult with the manufacturer or a qualified technician.

Gigabit Ethernet Slip Rings Maintenance and Troubleshooting

Proper maintenance and troubleshooting of Gigabit Ethernet slip rings is crucial to ensure their longevity and maintain optimum performance. This process involves periodic checks and cleanups, along with prompt responses to problems.

Routine Checks and Cleanup:

Routine inspection involves checking the Gigabit Ethernet slip rings visually for dust, debris, and signs of wear and tear. Any contaminants should be promptly removed with an approved cleaning agent, avoiding any substances that could cause harm to the slip ring or its components. Additionally, it’s important to monitor the operation of the slip ring regularly to identify any unusual noise or performance irregularities.

The wires connected to the slip ring should also be periodically checked for any breaks, insulation damages, or loose connections. If found, they should be repaired or replaced as needed.

Common Problems and Solutions:

- Transmission Errors: Communication errors could be due to wiring issues- either misconnection or damaged wires. The remedy may involve reconnecting the wires correctly or replacing damaged ones.

- Noise Generation: Excessive noise could indicate wear and tear of the slip ring. Regular inspections and maintenance can generally prevent this issue, but if the noise persists, the slip ring may need to be replaced.

- Heat Generation: If the slip ring generates excessive heat during operation, this could be indicative of overload. This issue could be circumvented by adjusting the power load to align it with the slip ring’s specified capacity.

- Loss of Connectivity: This could be due to a deterioration in the connection quality prompting a need for component cleaning or replacement. If the problem persists, it may indicate a more serious internal issue requiring expert attention.

By incorporating regular maintenance into the operational routine and quickly addressing problems as they arise, the life span and performance of Gigabit Ethernet slip rings can be significantly maximized. As these devices play a vital role in various systems, ensuring their optimal functioning is a prerequisite for the system’s overall performance and efficiency.

Future Trends and Advancements in Gigabit Ethernet Slip Rings

The technology behind Gigabit Ethernet slip rings is rapidly evolving in response to increasing demands for faster and more reliable data transmission. As industrial applications and technologies advance, so too do the associated requirements for enhanced data and power transmission that slip rings can accommodate.

One of the emerging trends is the integration of fiber optic rotary joints with slip rings. Fibre optic rotary joints (FORJs) are used to transmit optical signals between stationary and rotating parts of a system. When combined with Gigabit Ethernet slip rings, they allow for simultaneous transmission of electrical and optical signals, greatly enhancing the amount of data that can be transferred. This innovation has broadened the utility of slip rings in systems that require high data transfer capability, such as radar and satellite communication systems.

High-speed slip rings have also become a new essential, especially in industries such as telecommunications, where data transmission speed is paramount. These high-speed slip rings, coupled with Gigabit Ethernet capability, are further enhancing the scope of these critical components, enabling them to handle the growing demand for high-speed, high-volume data transmission.

Wireless slip rings represent another significant future trend. This technology operates by using inductive coupling to transmit power and electrical signals between the stationary and rotating parts in a system, eliminating the need for physical contact. This breakthrough could lead to significant reductions in maintenance requirements and increase the durability and reliability of these systems.

In terms of future advancements, we can expect to see AI and IoT integration. For instance, we could see the development of smart slip rings that can self-diagnose and report their functional status, alert users in case of need for maintenance or replacement, and even perform basic troubleshooting. This could significantly reduce downtime, simplify maintenance procedures, and increase the overall efficiency of the systems in which they are used.

Overall, the world of Gigabit Ethernet slip rings is in the midst of an exciting period of innovation and advancement. Continuing evolution and adaptation to new technologies are reshaping this sphere, enabling higher efficiency, reliability, and convenience in myriad applications. By staying updated with these key advancements, industries relying on these components can leverage the benefits that these future trends offer, thereby enhancing their operational efficiency and competitiveness.

Enter your information to receive product catalogs and brochures for Ethernet Slip Rings.

Questions & Concerns about Gigabit Ethernet Slip Rings

When it comes to Gigabit Ethernet slip rings, potential users often have several areas of concern. Below we address some common areas:

- Compatibility: A common question is about compatibility – both in terms of fitting into specific machinery and the ability to work with the system’s existing infrastructure. Compatibility largely depends on the slip ring model and the equipment in question. Fortunately, manufacturers often produce slip rings in numerous configurations to suit different needs, and can often customize them to fit unique requirements.

- Cost: The cost of Gigabit Ethernet slip rings can vary significantly based on their complexity, capacity, employing technology, and specific model. It’s crucial to balance this cost with the device’s potential benefits like improved system efficiency, data transmission speed, and reliability.

- Lifespan: The lifespan of a Gigabit Ethernet slip ring can be influenced by several factors, including the quality of manufacturing materials, the operating environmental conditions, and how well the device is maintained. With proper care and maintenance, these slip rings can have a considerably long life span, often running into several years.

- Maintenance Requirements: Maintenance includes regular inspection, cleaning, and prompt repair of any identified faults. Regular maintenance enhances the lifespan of the slip ring and ensures its effective performance. Most high-quality Gigabit Ethernet slip rings are designed to require minimal maintenance. Still, the exact maintenance requirements depend on the specific model and the manufacturer’s instructions.

In conclusion, while these common concerns are valid, most can be addressed effectively by careful selection of the slip ring model, adhering to the manufacturer’s instructions for installation, operation, and maintenance, and consulting with the manufacturer or a qualified technician when in doubt. Furthermore, the benefits offered by these slip rings – particularly their ability to facilitate high-speed and reliable data transmission in rotating systems – often outweigh these concerns, making them an integral component of many modern systems.

Conclusion

Overall, choosing the right gigabit ethernet slip ring is a cornerstone for tech-intense applications requiring high-speed data transmission. By understanding their core features, maintenance needs, and future trends, users can immensely benefit from the impeccable advantages they offer. With the rapidly advancing technological landscape, one can anticipate even more potential applications and enhancements for these game-changing elements.

See What We Can Do