We’ll begin by elucidating the fundamental concepts of squirrel cage induction, laying the groundwork for understanding how these motors operate and why they are designed the way they are. Delving into the past, we’ll explore the historical evolution that has transformed these motors from curious inventions into industrial cornerstones. From there, our exploration will guide us through the specifics of their design and construction, demystifying the materials and engineering choices that shape their performance and durability. A closer examination of their operation will reveal why these motors are favored in so many applications, and we’ll weigh their advantages against their limitations to appreciate their suitability for different tasks.

Introduction:Squirrel Cage Induction

The world of electric motors is vast and varied, with numerous types and configurations tailored to different needs and applications. Among them, the squirrel cage induction motor stands out for its simplicity, reliability, and efficiency. These motors are named for their unique rotor design, which resembles a hamster or squirrel wheel—hence the term “squirrel cage.”

Squirrel Cage Induction Motors: A Blend of Simplicity and Power

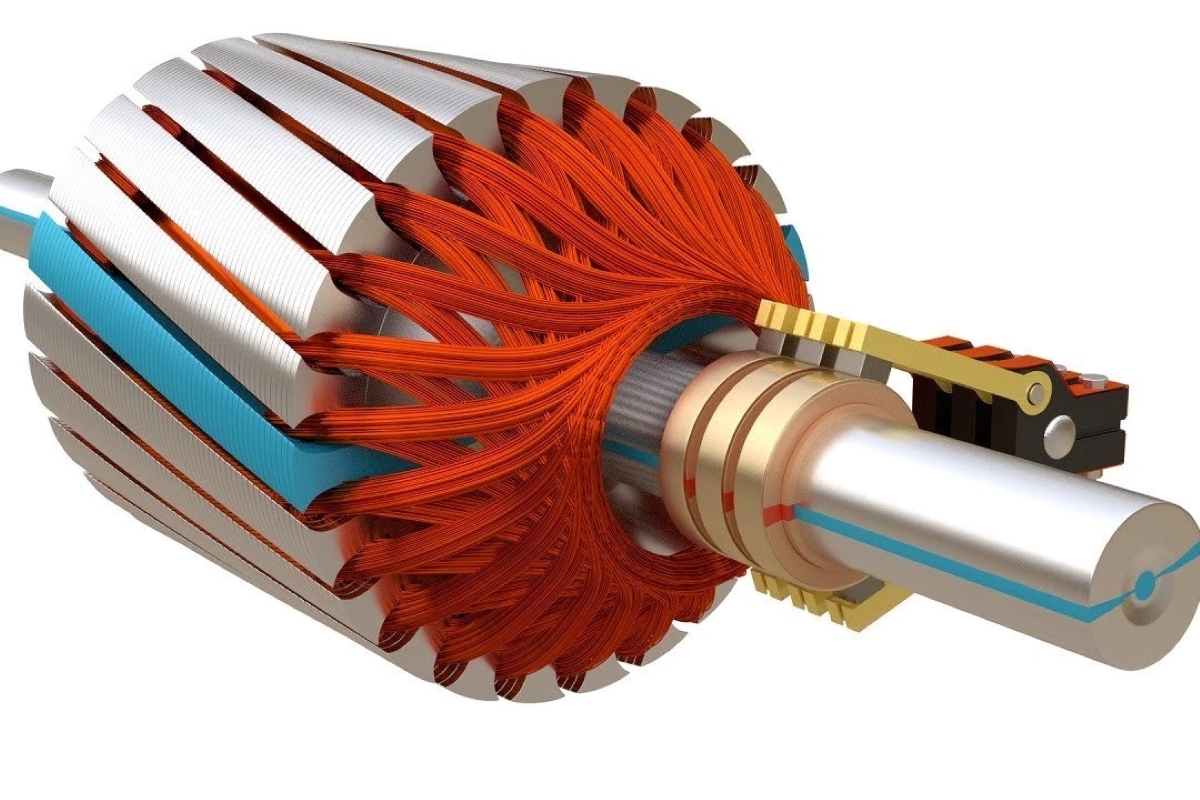

Within the steel frame of a squirrel cage induction motor lies a synergy of physics and engineering. The operation of these motors is rooted in the principles of electromagnetic induction discovered by Michael Faraday. The rotor in a squirrel cage induction motor is shaped like a cylindrical cage and is made up of aluminum or copper bars short-circuited by end rings. This simple yet ingenious construction underpins the robustness and wide usage of these motors.

A-Pillar of Contemporary Technology

It is no overstatement to say that squirrel cage induction motors are the unsung heroes of the modern industrial world. Their robustness and low maintenance make them the heart that powers countless machines. From domestic appliances like washing machines and refrigerators to driving conveyor belts in production lines and powering electric fans and pumps, these motors hum in the background, bringing to life the conveniences and necessities of contemporary living.

- We’ll begin by elucidating the fundamental concepts, laying the groundwork for understanding how these motors operate and why they are designed the way they are.

- Delving into the past, we’ll explore the historical evolution that has transformed these motors from curious inventions into industrial cornerstones.

- From there, our exploration will guide us through the specifics of their design and construction, demystifying the materials and engineering choices that shape their performance and durability.

- A closer examination of their operation will reveal why these motors are favored in so many applications, and we’ll weigh their advantages against their limitations to appreciate their suitability for different tasks.

The Basics of Squirrel Cage Induction

Sprouting the Seeds of Curiosity: What is Squirrel Cage Induction?

The term “squirrel cage induction” might trigger images of a furry creature running on a wheel. But while the name bears a whimsical charm, the concept it represents is firmly planted in the realm of electrical engineering. Squirrel cage induction refers to a particular type of electric motor in which the rotor is a cylindrical cage made from conductive bars short-circuited by end rings. These motors operate on the principle of electromagnetic induction, which is essentially the process of creating an electric current in a conductor by changing the magnetic field.

Unleashing the Power: How Do Squirrel Cage Motors Work?

While their design is relatively simple, the mechanics behind squirrel cage induction motors are a beautiful illustration of physics at work. In these motors, an alternating current (AC) is applied to the stator windings, creating a rotating magnetic field. This field interacts with the bars of the rotor, inducing a current in the rotor due to Faraday’s law of electromagnetic induction. The interaction of this induced current with the rotating magnetic field produces a torque, pulling the rotor into rotation. As the rotor chases the ever-rotating field, it never quite catches up, working in slight lag, a characteristic known as slip.

Comparative Analysis: Squirrel Cage vs. Other Motors

Squirrel cage induction motors distinguish themselves from other motor types in several key ways. While direct current (DC) motors, for example, require brushes & commutators for operation which need regular maintenance, squirrel cage motors are brushless, resulting in less maintenance and higher reliability. Compared to other AC motors, like the wound rotor or synchronous motors, squirrel cage motors are more straightforward to manufacture, more robust, and require less maintenance, although they have less starting torque and speed control.

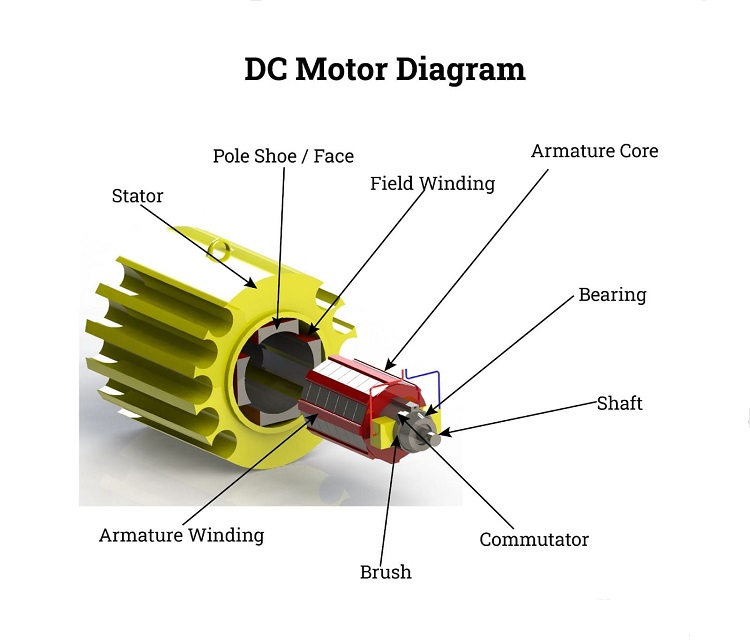

Dissecting the Device: Key Components of a Squirrel Cage Motor

At a glance, a squirrel cage induction motor might appear complex. Yet, its design is relatively simple, comprising a few key components:

- The stator is the stationary part of the motor with windings that carry the supply current to generate a rotating magnetic field.

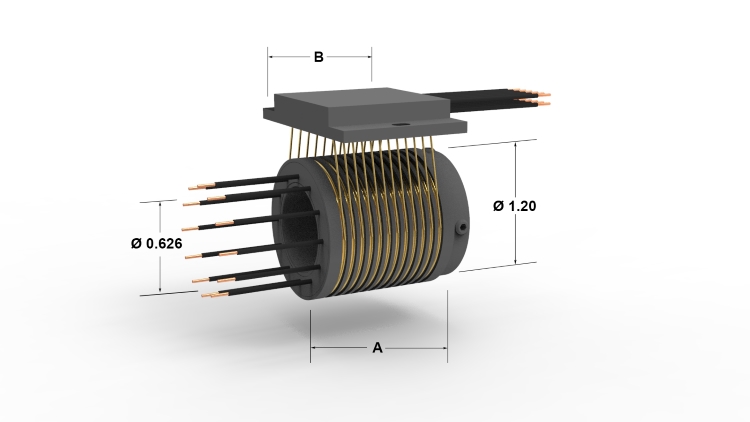

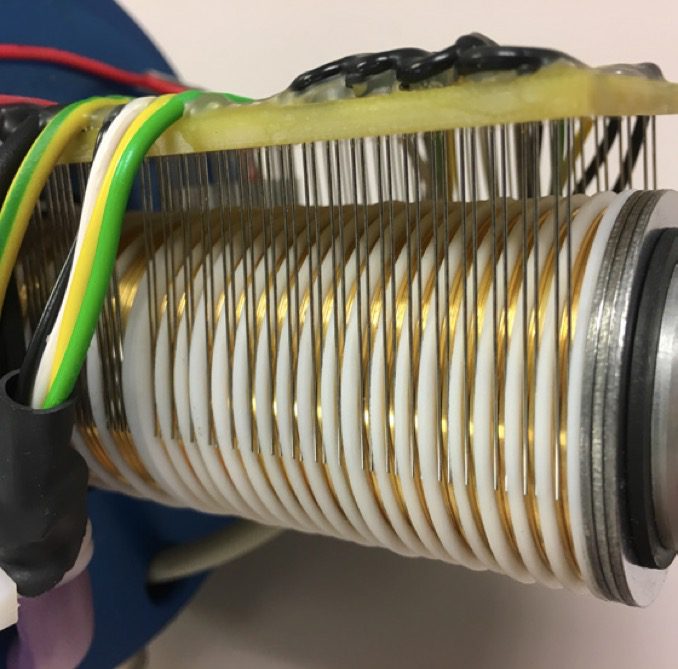

- The rotor carries the cage-looking winding, named the squirrel cage, composed of conducting bars connected by end rings.

- The bearings support the rotor, allowing it to rotate smoothly within the stator.

- The frame (or enclosure) protects the interior components and aids in heat dissipation.

Each element works in harmony within the motor, which all contribute to the final operation.

This chapter sets the stage for a great journey into the heart of these intriguing devices. Continued exploration will shed light on the history of their evolution, the specifics of their design, and their diverse applications, thereby illuminating why squirrel cage induction motors are worth our attention. Replete with practical examples, common questions, and misconceptions, this nuanced tour de force challenges and engages the reader, rendering complex concepts into digestible narratives. Stay plugged in—there are plenty of illuminating discoveries ahead!

Historical Perspective of Squirrel Cage Induction

Tracing the Roots: The Evolution of Squirrel Cage Induction Motors

To appreciate the modern marvel that is the squirrel cage induction motor, we must march back in time to witness the evolution of these engines of change. From the early experiments with electromagnetic induction to the streamlined manufacturing of today – each step in their evolution has been punctuated by improvements and innovations that have incrementally but fundamentally altered the technological landscape.

The tale begins in the 19th century when pioneers of electromagnetism set the stage. The discovery of the relationship between electricity and magnetism spawned a slew of inventions and concepts that would eventually lead to the creation of the first practical induction motors.

The Architects of Rotation: Key Inventors and Milestones

Nikola Tesla, a name that echoes through the annals of electrical engineering, was pivotal in the development of the AC induction motor. In 1888, he was granted a patent for an “electro magnetic motor” which laid the foundational design of the modern squirrel cage induction motor. Tesla’s design essentially harnessed a rotating magnetic field to turn the motor’s rotor—a breakthrough that revolutionized how motors would be viewed.

Following Tesla, other inventors such as Mikhail Dolivo-Dobrovolsky and Charles Steinmetz made significant contributions, refining the induction motor and integrating it into the burgeoning electrical grid. Each milestone in this journey marks a leap in understanding and application, transforming these machines from mere curiosities to the driving force behind the Second Industrial Revolution.

Forging Ahead: Technology Advancements Shaping Motor Development

The historical narrative of squirrel cage induction motors is also a testament to humanity’s relentless pursuit of efficiency and performance. With each passing decade, advancements in material science and manufacturing techniques have raised these motors to new heights. The introduction of high-performance insulation materials, for instance, has allowed for higher operating temperatures and efficiencies, while computer-aided design has dramatically improved performance and predictability.

Moreover, the proliferation of power electronics and digital controls has brought about unprecedented precision in the control of motor speed and torque, expanding their applicability across a swath of industrial and commercial applications.

As we reflect on this rich tapestry of vision and innovation, we understand that the squirrel cage induction motor is not merely a product of history, but a driver of it. Stories of factories electrified, of the assembly lines accelerated, of the everyday lives transformed—these are the testaments to the motor’s impact.

The following chapters will build on this historical insight, delving into the mechanical and electromagnetic symphony that enables these motors to convert electrical energy into motion—inviting you to grasp not just the how and the what, but the why of squirrel cage induction motors. Stay tuned as we turn the page and continue to unravel this captivating narrative that twirls endlessly like the rotor in an induction motor.

Design and Construction of Squirrel Cage Induction Motors

Zooming In on the Blueprint: Insights into Design Features

Before embarking on our deep dive into the design and construction of squirrel cage induction motors, let’s appreciate that great engineering excels at simplicity. And it’s this simplicity that has been at the heart of the durability and accessibility of these motors.

The design of squirrel cage induction motors typically features a stationary part, the stator, and a rotating part, the rotor. The stator houses windings for the three-phase AC current (in most commercial motors) that produce a rotating magnetic field. An iron core rotor, resembling a cage, sits within this stator. When the rotating magnetic field passes over this rotor, it induces a current and generates an opposing magnetic field, resulting in torque that drives the rotor to spin.

The Fabric of Operation: Materials Used in Construction

The choice of materials employed in the construction of squirrel cage induction motors significantly impacts their performance, reliability, and efficiency. Let’s explore some key materials:

- The stator and rotor cores are typically made from laminated silicon steel. Lamination reduces power losses due to eddy currents, while silicon steel improves magnetic properties.

- Copper or aluminum bars form the “squirrel cage” in the rotor. Copper has higher conductivity but is more expensive, while aluminum, though less conductive, is lighter and cheaper.

- The frame or housing can be crafted from cast iron, aluminum, or steel, depending on the motor’s intended use. These materials provide protection and help with thermal management.

Interplay of Choices: Design Variations & Performance Impact

While the essential principles remain the same, squirrel cage motors can be designed with specifications tailored to specific applications.

- For instance, motors designed for industrial use, where high starting torque is important, often use a ‘deep bar’ rotor design, having deeper, narrower bars in the rotor, which results in greater torque and improved performance under load.

- Motors intended for constant speed applications (like fans or pumps) often employ a ‘shallow bar’ design. These are generally more efficient but offer lower starting torque.

Through understanding these intricacies in design and construction, we gain a panoramic view of the practical considerations and intricate trade-offs that shape the squirrel cage induction motors humming around us.

As we progress through the later chapters, we’ll explore the different types of squirrel cage induction motors and how to discern which one is ideal for specific scenarios. Remember, every turn of the rotor and every hum of the motor tells a story—a tale of thoughtful design morphing into the industrious hustle of everyday life.

Operating Principles of Squirrel Cage Induction Motors

Delving into the Dynamics: How Squirrel Cage Motors Spring to Life

At first glance, the operation of squirrel cage induction motors might seem steeped in a sort of arcane magic—silent, efficient, and devoid of visible moving parts at the surface. But beneath this cloak of simplicity lies a fascinating interplay of magnetic fields and electric currents.

The Magic of Electromagnetic Induction

The sorcery begins with the principle of electromagnetic induction, discovered by Michael Faraday in the 19th century. When an alternating current flows through the stator windings of the motor, it creates a rotating magnetic field. This magnetically charged whirlwind cuts through the rotor, which, although made of conducting material, is not connected to any power source.

As the rotating field sweeps past the rotor bars, it induces a current in them due to electromagnetic induction—the phenomenon where a changing magnetic field in a conductor induces a current in that conductor. The induced current in the rotor bars, in turn, generates its magnetic field which interacts with the stator’s magnetic field.

The Pull of Rotation: Torque and Its Dance with Speed

This interaction between the stator’s magnetic field and the rotor’s magnetic field results in the development of torque—the twisting force that causes rotation. The beauty of this system is that the rotor, chasing the stator’s magnetic field, attempts to catch up with the rotation but never actually does during normal operation. This lag between the stator field’s speed and the rotor’s speed is referred to as “slip.”

Torque-Speed Characteristics: The Heartbeat of Performance

The torque-speed characteristic of a squirrel cage induction motor defines its performance. At startup, when the rotor is stationary, the slip is maximum, and the motor generates maximum torque, known as the starting torque. As the rotor accelerates, the slip decreases, reducing the torque. A fascinating aspect of squirrel cage motors is their ability to adjust torque in response to load requirements, making them incredibly resilient and adaptable across various applications.

This performance curve highlights an important characteristic: the nearly constant speed under varying loads, making squirrel cage induction motors the workhorses behind everything from large industrial machinery to household appliances.

In Practice: Squirrel Cage Motors at Work

Consider the case of conveyor belts in a manufacturing plant. These belts must start under load, requiring high starting torque. Once operational, they maintain a constant speed, despite the varying weight of the products they carry. It’s here that the unmatched efficiency and adaptability of squirrel cage induction motors shine, propelling operations with reliability and precision.

In this chapter, we’ve demystified the principles of propelling squirrel cage induction motors. But as with any profound technology, understanding breeds even more questions. How do we enhance these motors for energy efficiency? What innovative applications are emerging? Join me in the next chapters as we continue to explore these industrious machines that, quite literally, make the world go round.

Advantages and Limitations of Squirrel Cage Induction Motors

The Symphony of Strengths: Energy Efficiency and Reliability

In the world of electric motors, the squirrel cage induction motor is akin to a valiant workhorse—robust, dependable, and stalwart. But why is this? One word: efficiency. Composed to perform without extravagance, these motors have a very good power factor, which translates to highly efficient operations, especially under full load conditions. This efficiency stems from the simplicity of their design—few moving parts, no brushes, and no slip rings.

Steadfast Companions: The Reliability of Squirrel Cage Motors

When it comes to reliability, these motors are the ones you take home to meet the family. Their rugged construction ensures they can weather the harsh conditions of industrial environments, from the incessant dust of sawmills to the moist air of paper mills. Plus, their lack of brushes means no sparks—making them less prone to ignition and a preferred choice in hazardous conditions.

Easing the Burden: Low Maintenance Requirements

With fewer moving parts than their cousins—brushed motors—squirrel cage induction motors seldom throw a tantrum needing attention. The squirrel cage design quells the need for frequent maintenance and makes these motors notably long-lived. No brushes or commutators to replace means the primary maintenance concern is often just bearing lubrication and periodic checks.

Navigating the Challenges: Limitations and Application Suitability

However, perfection remains an elusive pursuit, and even squirrel cage induction motors have limitations.

- Starting Torque and Control: They typically have lower starting torque compared to other types, making them less suitable for applications requiring high torque at startup.

- Speed Variation: They operate best at a constant speed. While it’s possible to control their speed, it requires additional controllers such as variable frequency drives, which can add to the cost.

- High Inertia Loads: Ramping up to speed with loads that have high inertia can be a challenge, as these motors can overheat due to prolonged high current draw.

Case in Point: Real-World Applications

A case study of industrial ventilators illustrates the impact of these limitations. Required to operate continuously for long hours, the ventilators need motors that are reliable and demand minimal maintenance—a perfect role for squirrel cage motors. However, if a specific process requires varied airflow, adapting squirrel cage motors with speed controllers would be necessary, balancing their inherent limitations with the advantages they offer.

The Takeaway

Understanding the strengths and limitations of squirrel cage induction motors opens up the potential to harness their capabilities fully while accommodating their shortcomings. Just as a maestro selects the right instrument for each passage of a symphony, so must an engineer choose the right motor for each application.

In the next chapter, we’ll explore the innovative solutions engineers have devised to navigate the limitations of these motors, drawing yet more performance from this classic but ever-evolving technology.

Applications of Squirrel Cage Induction Motors

The Versatile Virtuoso: A Spectrum of Applications

Squirrel cage induction motors, the unsung heroes of electromechanical energy conversion, have found their stage across an array of applications—each showcasing their versatility and resilience. From the labyrinthine networks of industrial conveyors to the daily hum of household appliances, these motors are omnipresent, albeit often unnoticed by the layperson.

Industrial Maestros: Pioneering Efficiency and Productivity

Industrially, squirrel cage induction motors have been pivotal in revolutionizing processes. Their reliability and low maintenance make them ideal for driving machinery that demands continuous operation, such as pumps, fans, and conveyors. For example, in the water treatment industry, these motors ensure pumps operate seamlessly, circulating water through vast networks of treatment facilities and pipelines, thereby playing a silent but critical role in maintaining public health and hygiene.

On the Move: Propelling Transportation

In transportation, though less visible than their internal combustion counterparts, squirrel cage induction motors are making significant inroads, particularly in electric vehicles (EVs) and public transportation systems. The Tesla Model S, for instance, employs an advanced form of this motor, chosen for its simplicity, robustness, and efficiency. This not only illustrates the adaptability of squirrel cage motors to modern demands but also underscores their potential to contribute to sustainable transport solutions.

Homebound Harmony: Easing Daily Life

Within the domestic realm, these motors are the heartbeat of numerous appliances. From the cooling breeze of air conditioners to the essential spin of washing machines, squirrel cage induction motors help streamline chores, making daily life smoother and more comfortable. Their quiet operation and durability mean they can be relied upon day in, day out, without a second thought from homeowners.

Illuminating Case Studies: Milestones of Innovation

Delving into specific use cases brings the versatility of squirrel cage induction motors into sharper focus. An illustrative case is their deployment in automated warehouses, where speed, efficiency, and reliability are paramount. These warehouses, operated by global retail giants like Amazon, leverage the motor’s capabilities to run conveyors and lifts that sort and transport goods tirelessly—demonstrating an impressive synchronization of speed and accuracy.

Envisioning the Future: Unleashing Potential

Looking to the horizon, the potential applications of squirrel cage induction motors seem boundless. With the burgeoning interest in renewable energy, these motors are set to play a crucial role in wind turbines. Their simplicity and durability can maximize efficiency and reduce maintenance in these harsh environments, significantly contributing to sustainable energy goals.

Moreover, as the world leans more towards automation and robotics, the dependable nature of these motors ensures they will be integral in driving robots and automated systems across manufacturing and beyond—proving yet again that their journey from the past into the future of technology is far from over.

In conclusion, squirrel cage induction motors, through their broad spectrum of applications, have displayed an extraordinary capacity to adapt, evolve, and thrive. As we’ve journeyed through the realms of industry, transportation, and our homes, it’s clear that their silent operation belies a transformative impact, making them unsung champions of the electrical world. Let’s turn the page to explore how innovation continues to unfold in the realm of these versatile motors.

Troubleshooting and Maintenance of Squirrel Cage Induction Motors

Deciphering Dilemmas: Common Issues and Diagnostics

The robustness and reliability of squirrel cage induction motors are well-documented, yet they are not immune to the wear and tear of continuous operation. Recognizing and rectifying common issues is crucial to maintaining their efficiency and longevity.

- Overheating: Often traced back to overload conditions, inadequate cooling, or environmental factors. Using a thermal imager or even a simple touch test (carefully) can help identify hotspots indicative of issues ranging from bearing failure to improper ventilation.

- Vibration: Excessive vibration can signal misalignment, bearing wear, or an imbalance in the motor or the driven load. Employing vibration analysis tools can pinpoint the source, guiding corrective measures.

- Unusual Noises: Sounds like grinding or screeching may hint at bearing issues or rotor bar damage. Listening closely can help diagnose the problem before it exacerbates.

- Reduced Performance: If a motor starts exhibiting signs of slowdown or inefficiency, checking electrical connections, voltage levels, and the condition of the rotor can help identify electrical issues, including those caused by supply imbalances or worn contacts.

Prevention is Better Than Cure: Maintenance Tips

Routine maintenance can significantly extend the lifespan of squirrel cage induction motors and ensure they operate at peak efficiency. Here are some tips:

- Regular Cleaning: Keeping the motor and its vents clean from dust and debris ensures adequate cooling and prevents overheating.

- Lubrication: Bearings need regular lubrication to reduce friction and prevent wear. However, over-lubrication can attract dirt or cause excessive grease buildup, so follow the manufacturer’s guidelines.

- Routine Inspection: Periodic checks of the motor, its mountings, and electrical connections can preempt failures. Pay special attention to bearing condition and brush wear (if applicable).

- Balancing and Alignment: Ensure that both the motor and the driven equipment are properly aligned and balanced to avoid excessive vibration and bearing loads.

Making the Call: Repair vs. Replace

Deciding whether to repair or replace a squirrel cage induction motor depends on several factors, including the extent of damage, cost implications, and potential technological upgrades.

- Cost Considerations: If the cost of repair approaches or exceeds 50% of the cost of a new motor, replacement might be more economically feasible, considering also the efficiency gains and warranty benefits of a new motor.

- Technological Advances: In some cases, replacing an older motor with a modern, more efficient model can offer long-term savings through reduced energy consumption and maintenance needs.

- Historical Performance: If a motor has been a perennial source of trouble or its performance has degraded, investing in a new unit could improve reliability and productivity.

Real-World Application: A Maintenance Success Story

A telling example comes from a manufacturing facility that implemented a predictive maintenance program for their squirrel cage induction motors. By closely monitoring vibration analysis data, they preempted the failure of a critical motor driving a production line conveyor. Early detection of bearing wear allowed them to schedule repairs during planned downtime, avoiding significant production losses and exemplifying the tangible benefits of proactive maintenance.

In this chapter, we’ve navigated through the realms of troubleshooting and maintenance of squirrel cage induction motors, equipped with knowledge on preempting common issues, tips for upkeep, and insights on making informed repair or replacement decisions. This proactive approach not only enhances performance but also secures the reliability of operations, ensuring these motors continue to be the powerhouses of industry and daily life.

Squirrel Cage Induction Motor Innovations and the Future

As we delve into the future of squirrel cage induction motors, it becomes evident that the journey of innovation is far from reaching its zenith. The relentless pursuit of efficiency, reliability, and integration with modern industrial trends paints an exciting landscape for these electromechanical workhorses.

The Vanguard of Efficiency: Recent Advancements

Advancements in materials science and engineering have ushered in a new era for squirrel cage induction motors. The development of high-strength, lightweight materials has led to improvements in motor efficiency and power density. For instance, the use of advanced magnetic materials reduces core losses, while improvements in insulation materials enhance thermal management and longevity.

One noteworthy breakthrough is the integration of variable frequency drives (VFDs) with squirrel cage motors, which has significantly optimized energy consumption by allowing precise control of motor speed and torque in response to varying load requirements. This synergy not only trims down energy costs but also minimizes wear, extending the motor’s operational life.

A Digital Revolution: Impact of Digitalization and Automation

The digitalization wave has not bypassed the realm of squirrel cage induction motors. Smart sensors and Internet of Things (IoT) technology have become pivotal in monitoring motor performance in real time, providing insights into parameters such as temperature, vibration, and efficiency. This granular visibility enables predictive maintenance strategies, preempting failures and slashing downtime.

Furthermore, the advent of automation and robotics in manufacturing processes has propelled the demand for motors that can perform with greater precision and adaptability. Squirrel cage induction motors, armed with intelligent control systems, are stepping up to meet these demands, offering enhanced performance metrics and seamless integration into automated workflows.

Navigating the Future: Trends and Research Directions

Looking ahead, several trends and research directions stand out as potential game-changers for squirrel cage induction motors:

- Energy Efficiency Crusade: As global energy policies tighten and sustainability goals become more ambitious, research continues to focus on pushing the boundaries of motor efficiency. Innovations aim at further reducing electrical and mechanical losses and improving the overall design and manufacturing processes.

- Electrification and Mobility: The electrification of transport systems, including electric vehicles (EVs) and electric aviation, presents a burgeoning domain for squirrel cage motors. Advances in compact, high-performance motors that can withstand the rigors of mobility applications are on the horizon.

- Advanced Control Algorithms: The incorporation of sophisticated control algorithms, leveraging machine learning and artificial intelligence (AI), promises to revolutionize how squirrel cage motors are managed. These technologies could enable self-optimizing motors that adjust operational parameters in real time for unparalleled efficiency and performance.

Real-World Innovation: Case Study of Adaptive Motor Performance

A groundbreaking application of these innovations can be seen in a case study from the renewable energy sector. A large wind farm deployed advanced squirrel cage induction motors equipped with IoT sensors and VFDs in their wind turbines. These motors not only adapted efficiently to variable wind speeds but also utilized predictive maintenance algorithms to schedule servicing proactively. The result was a notable uptick in energy production and a reduction in operational interruptions, encapsulating the transformative potential of contemporary motor technology innovations.

In conclusion, Chapter 8 unveils a journey into the evolving landscape of squirrel cage induction motor innovations and their symbiosis with the future of industrialization, digitalization, and sustainability. It’s a testament to the enduring relevance of these motors and their capacity to adapt and thrive amidst the tidal waves of technological advancement. As we stand on the cusp of this new era, the possibilities and challenges ahead promise to reshape our understanding and utilization of squirrel cage induction motors in ways we are just beginning to imagine.

Embracing the Electrical Workhorse

As we reach the culmination of our exploration into the robust world of squirrel cage induction motors, it is vital to reflect upon the key insights that make this topic not only intellectually enriching but also practically invaluable for both seasoned professionals and zealous enthusiasts.

Recapitulation of Key Insights

Fundamentals and Innovations: In earlier discussions, we unraveled the basics of how squirrel cage induction motors function, their innate design superiority, and the consequent proliferation in various sectors. We traced the technological trajectory that has transformed them from simple, fixed-speed units to sophisticated, energy-efficient components in modern machinery.

Design and Application: We examined their intricate design elements, dissected the roles of stators and rotors, and the delicate art of choosing the right motor for a given task. Through real-world applications in industries like manufacturing, transportation, and renewable energy, we showcased the adaptability and resilience of these motors.

Upkeep and Troubleshooting: Maintenance philosophies and the repercussions of neglect were deliberated, with an emphasis on proactive steps for prolonging motor life and ensuring operational efficiency, thus reducing downtime and costs.

Enhancing Professional Aptitude and Curiosity

For professionals in the field, comprehension of squirrel cage induction motors is no trivial matter—it can be the differentiator between a system that is merely functional and one that is optimally performance-tuned. It speaks to the heart of machinery reliability, energy conservation, and cost-efficient production.

Enthusiasts find in these motors a fascinating interplay of physics and engineering that can serve as a gateway to deeper exploration into the electromechanical world. The knowledge gained herein can become the foundation stone upon which innovative projects and aspirations are built.

A Catalyst for Continuous Learning

Embrace Emerging Trends: As technology progresses, the integration of smart sensors, IoT, VFDs, and AI into squirrel cage motor systems is becoming the norm. These advancements present an evolving landscape rich with potential for those keen to keep abreast of cutting-edge developments.

Seek Deeper Understanding: Dive into case studies like the wind farm that successfully harnessed the synergy of advanced motors and IoT sensors to enhance efficiency. Such instances underscore the real-world impacts of embracing and understanding these motors.

Join the Conversation: Engage with communities of experts and peers. Participate in discussions; attend seminars and workshops; contribute to journals and forums. Your insights and experiences can both inform and be enriched by the collective wisdom of the field.

Endnotes and Encouragements

It is the hope that this exploration into the world of squirrel cage induction motors has not only informed but also inspired me. The journey does not end here. Let curiosity be your compass and knowledge your roadmap as you continue to delve into the electrical engineering realm. Innovate courageously, maintain dutifully, and learn incessantly—for the horizons of understanding are boundless, and each day brings forth new electrical symphonies waiting to be mastered.